Metal face composite curtain wall board and curtain wall with same

A curtain wall panel and metal surface technology, applied in the direction of walls, building components, buildings, etc., can solve the problems of water and gas passing, troublesome installation process, failure of core material function, etc., to improve water tightness and air tightness, and improve wind resistance. The effect of easy performance and shape molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

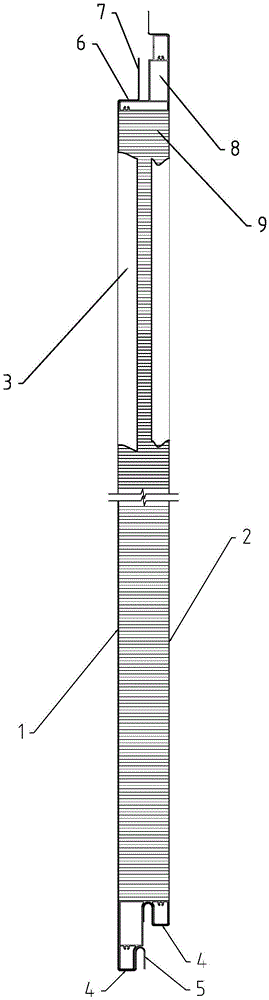

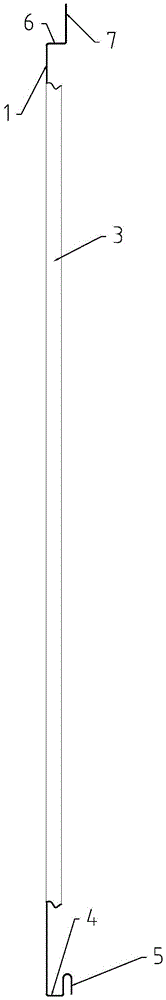

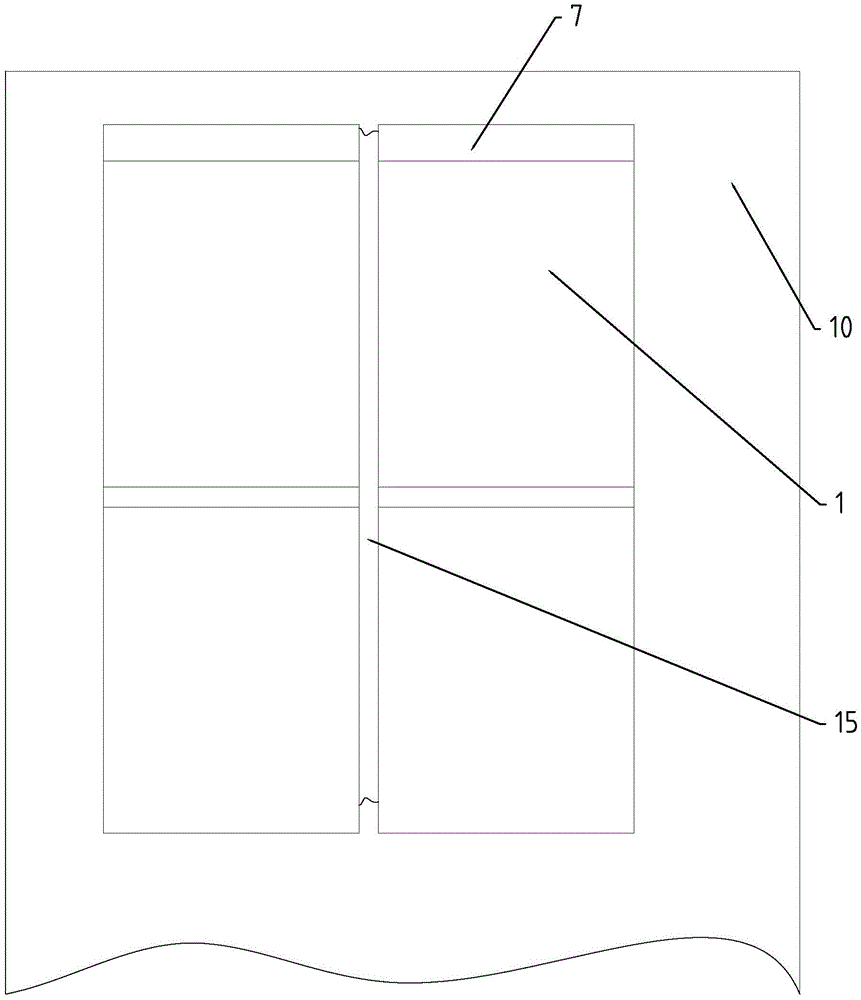

[0019] In order to clearly illustrate the technical features of this solution, the present invention will be described in detail below through specific implementation modes and in conjunction with the accompanying drawings.

[0020] Such as Figure 1-2 As shown, a metal-surface composite curtain wall panel includes an outer panel 1, an inner panel 2 having the same structure as the outer panel 1, and a sandwich layer sandwiched between the outer panel 1 and the inner panel 2, the inner panel 2 and the outer panel 1 are arranged face to face, and the outer panel 1 includes two opposite side parts and two opposite end parts, one side of the two sides is provided with a female port, and the other side is provided with a male port matching the female port, Both ends are provided with flanges 3 that bend toward the inner panel 2 and are perpendicular to the outer panel 1. An inverted U-shaped plate 5 connected to the first horizontal short plate 4, an open end of the inverted U-sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com