Experiment device and method for simulating drilling-production double-work-condition pit shaft sand carrying multi-phase flowing

An experimental device, multi-phase flow technology, applied in earth-moving drilling, flushing wellbore, wellbore/well components, etc., can solve the problem of lack of gas-liquid two-phase complex sand-carrying problem, limitation, inability to guarantee calculation accuracy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0081] Specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

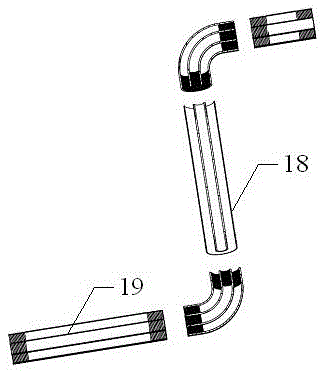

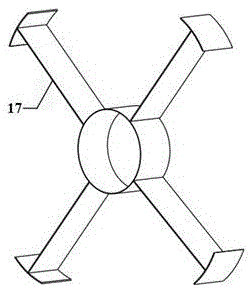

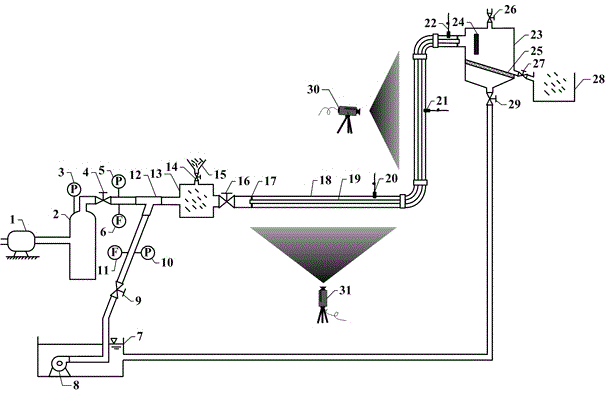

[0082] Such as figure 1 As shown, an experimental device for simulating sand-carrying multiphase flow in a wellbore under dual working conditions of drilling and production is composed of a gas supply system, a liquid supply system, a sand injection system, a test pipe section, a separation and recovery system, and a monitoring system. The air supply system is composed of an air pump 1, a stabilized pressure tank 2 and an air flow regulating valve 4. The air pump 1 is connected to the stabilized gas tank 2 through a pipeline. The tank pressure gauge 3 is installed on the top of the stabilized gas tank 2 to detect the inside of the tank. pressure. The top of the pressure-stabilizing gas tank 2 is connected to the Y-shaped tee 12 through a pipeline, and an airflow regulating valve 4 is installed on the pipeline. After the airflow regulating valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com