Ice source air exchanger with evaporative condenser

A technology of evaporative condensers and air exchangers, applied in the direction of water shower coolers, heat exchanger types, direct contact heat exchangers, etc., can solve problems affecting the operation of air conditioning systems, increased power consumption, and high cost, and achieve No geographical restrictions, high cooling efficiency, high heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to make the technical means, creative features, goals and functions achieved by the present invention clearer and easier to understand, the present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments:

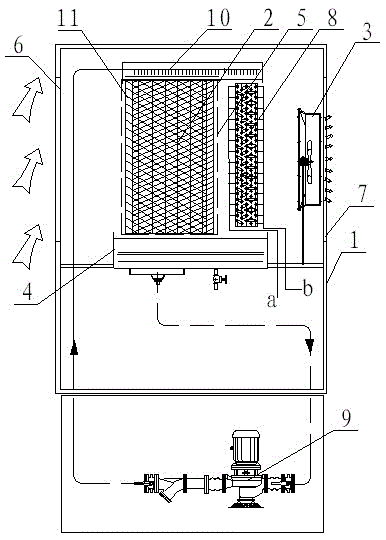

[0012] Such as Figure 1-3 As shown, the present invention includes a housing 1, a heat dissipation filler 2, a fan 3 and an ice source solution accumulation pool 4, wherein the heat dissipation filler 2 is filled in a filling chamber 5 provided in the housing 1, and between the filling chambers 5 An air inlet 6 and an air outlet 7 are arranged on the side wall of the housing 1 on the side, the fan 3 is fixed at the air outlet 7 of the housing 1, and an evaporative condenser is arranged in the housing 1 between the fan 3 and the filling chamber 5 8. The evaporative condenser 8 is close to the filling chamber 5. The inlet a of the evaporative condenser 8 is connected to the outlet pipe of the compresso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com