Core wire extruding production line for flame-retardant power cable

A production line and power cord technology, which is applied in the manufacture of circuits, electrical components, cables/conductors, etc., can solve the problems of flame-retardant power cord quality and output impact, long production process, complex process, etc., to achieve intelligent unmanned management , low cost, and the effect of ensuring product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to deepen the understanding and recognition of the present invention, the present invention will be further described and introduced below in conjunction with the accompanying drawings.

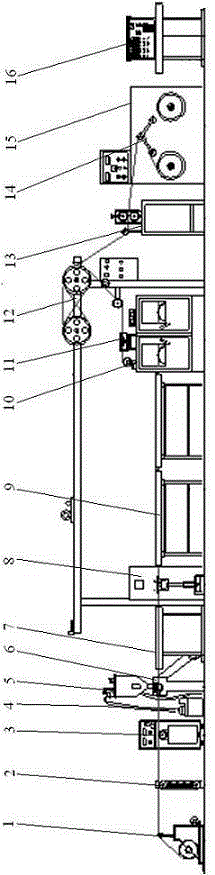

[0028] Such as figure 1 As shown, a core wire extrusion production line for flame-retardant power cords, including an electric power pay-off machine 1, a vertical tension frame 2, a wire preheater 3, an insulating plastic extrusion mechanism, and a cooling and drying mechanism arranged in sequence , traction mechanism 10, spark testing machine 11, wire storage tension frame 12, laser marking machine 13, wire take-up mechanism and PLC electric control platform 16.

[0029] The electric power pay-off machine 1 is equipped with a pay-off motor and a pay-off controller, and a plurality of tension wheels arranged on the vertical tension frame 2 are installed on the support shaft, and a balance potential is connected between the tension wheels. device, the balance potentiometer and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com