Safety apparatus for thermal battery soaked in high-temperature alkali liquor for discharging

A technology of safety device and high-temperature lye, which is applied to the parts of primary batteries, battery cover/end cover, battery pack parts, etc., can solve the limitation of the use environment and application range of hot batteries, and cannot meet the requirements and constraints of discharge. Heat battery and other issues, to achieve the effect of ensuring strength and operability, simple structure, and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

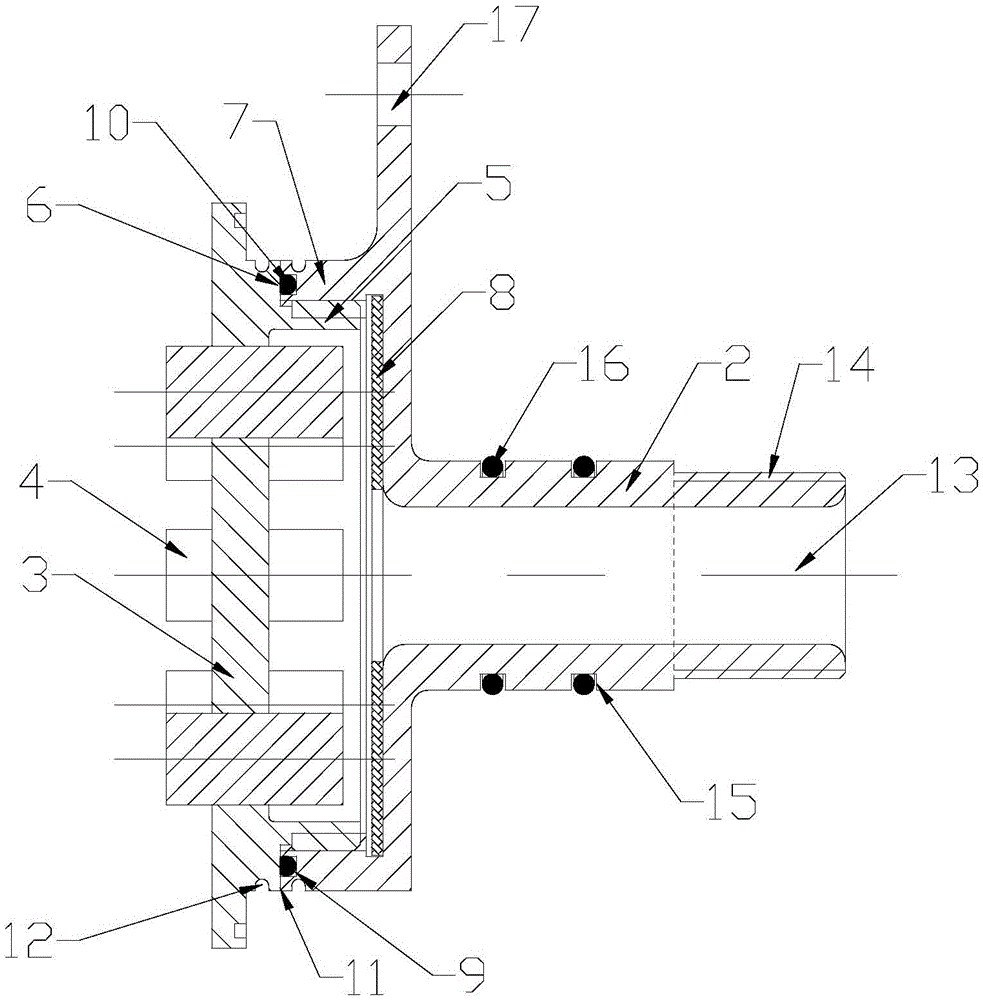

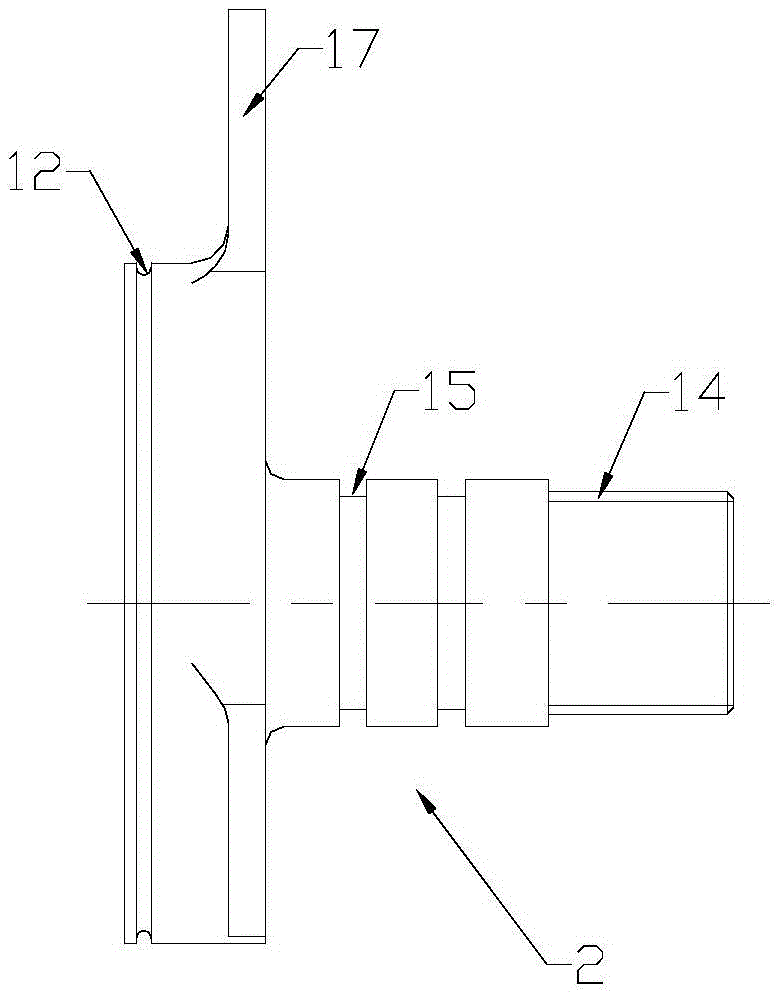

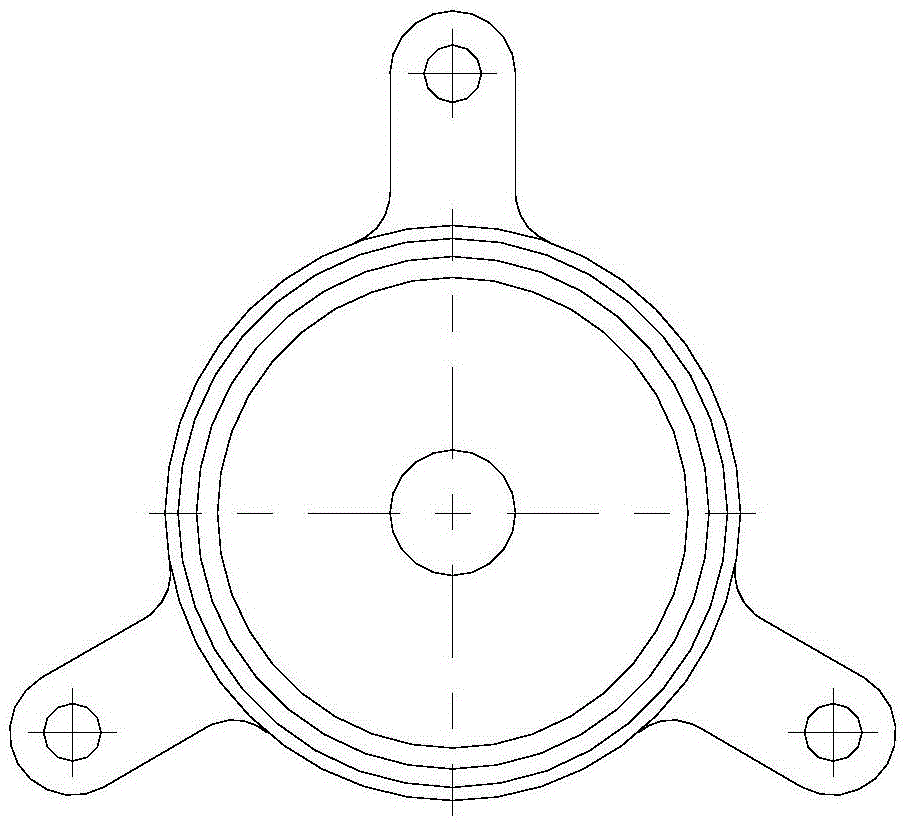

[0027] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0028] see Figure 1~5 , a safety device for discharging thermal batteries soaked in high-temperature alkaline solution, including a thermal battery cover 1 and a safety cap 2; the thermal battery cover 1 includes a battery cover body 3 with eight pole holes inside and a battery cover body 3 sealed and fixed in eight pole holes. The thermal battery pole 4 on the pole hole, the battery cover body 3 protrudes an external thread step 5 on the periphery of the thermal battery pole 4, and the outer raised edge 6 between the external thread step 5 and the battery cover body 3; safety The side wall of the cavity at 7 places on the outer edge of the protective cap is provided with an internal thread that matches the external thread of the battery cov...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap