Switch machine notch monitoring system and method based on binocular visual processing identification

A monitoring system and switch machine technology, applied in closed-circuit television systems, measuring devices, instruments, etc., can solve problems such as improving the difficulty and cost of system operation and upgrading, real-time high-definition transmission delay of images and videos, and inability to gap quantitative analysis. , to achieve the effect of enhancing the gold content of technology, reducing the difficulty of development, and reducing the tension of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be described in detail below in conjunction with the accompanying drawings and specific examples.

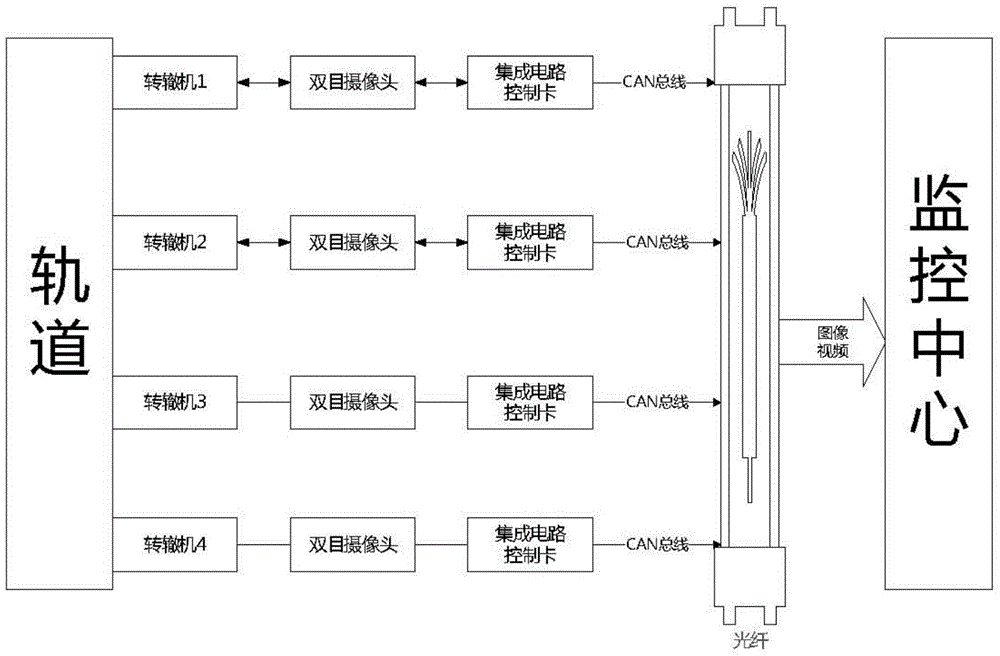

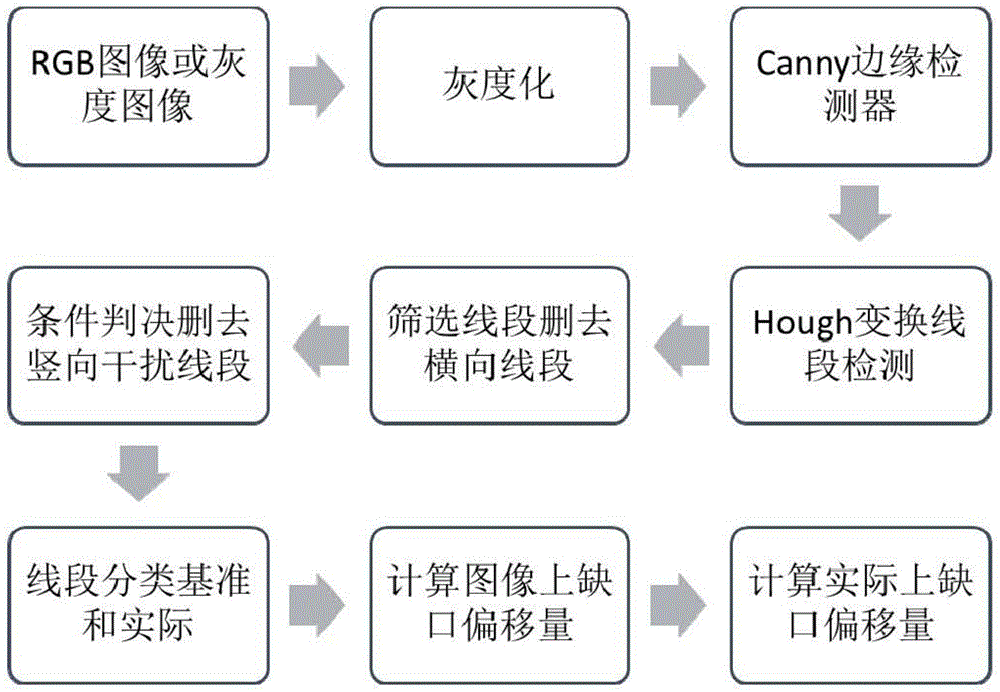

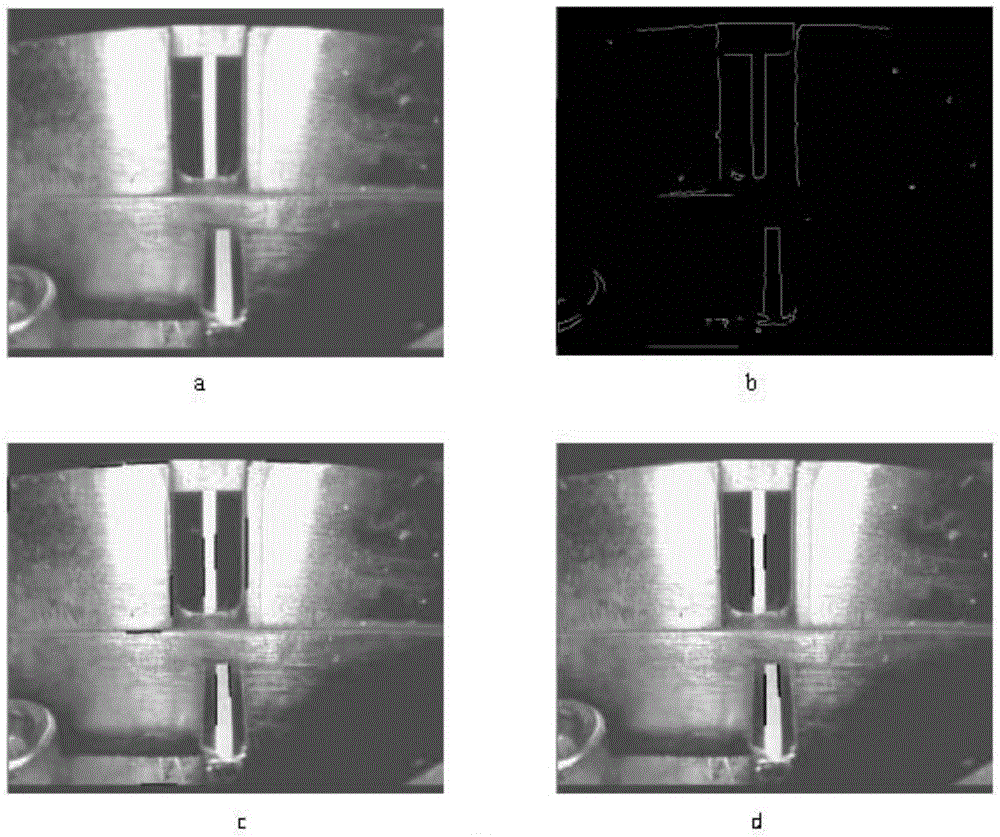

[0049] combine figure 1 As shown, the overall structure of the switch machine gap monitoring system is divided into three major subsystems: the on-site switch machine part, the CAN bus optical fiber transmission part, and the monitoring center part. In the on-site switch machine part, the system needs to install a binocular high-definition camera, aim the lens of the camera at the gap position of the track, and place the two cameras on the left and right symmetrically. The camera is connected to the integrated circuit control card through the USB interface, and the integrated circuit control card Based on the ARM and Linux platforms, the data collected by the camera is encoded, stored, compressed and other operations. In the monitoring center, an image visual processing and recognition system is running. This system processes image and video da...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com