Isothermal forging forming method for clamping plate forge piece made of 2024 aluminum matrix composite

An aluminum-based composite material and isothermal forging technology, which is applied in the field of warm forging, can solve the problems of difficult forging forming, unsatisfactory filling of forgings, easy folding at the cross-section transition, etc., and achieves the effect of improving the forming quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0021] The main chemical element content (percentage by weight) of the 2024 aluminum-based composite material is: Mn content 0.56%, Si content 0.065%, Cr content 0.0026%, Ti content 4.14%, Cu content 4.00%, Fe content 0.019% %, B content is 1.94%, Mg content is 1.52%, Zr content is 0.014%, and the balance is Al.

[0022] The steps of this method are as follows:

[0023] Take a blank of 2024 aluminum-based composite material of a certain specification, put it into an electric furnace, heat it to 420°C, and keep it warm for 270 minutes;

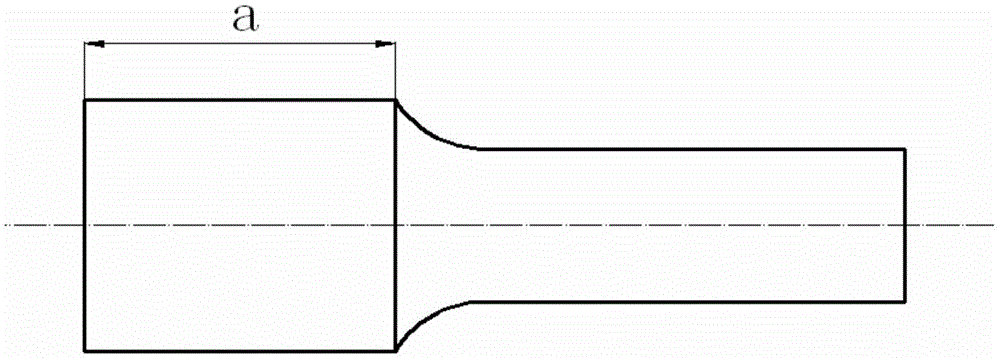

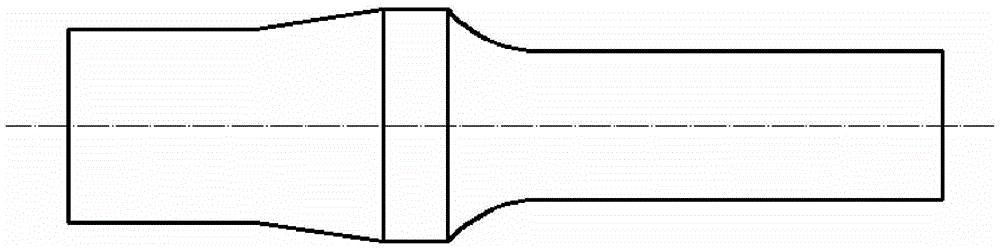

[0024] Take out the billet after heat preservation, upsetting on the free forging hammer, and then elongate; control the left end of the billet to remain unchanged, divide and elongate the distance a from the left end of the billet, and then flatten the billet as a whole, as shown in 1 ; Then the left end of the blank is drawn and shaped to make a middle blank, as shown in 2;

[0025] Return the intermediate billet to the furnace and heat it ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com