A kind of preparation method of non-metal element doped carbon-coated metal nanoparticle magnetic composite material

A technology of metal nanoparticles and magnetic composite materials, which is applied in metal processing equipment, transportation and packaging, etc., can solve the problems of inability of the pyrolysis process of metal precursors, non-metallic element doping, and non-magnetic carbon coating materials. , to achieve the effect of high degree of graphitization, large specific surface area and good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

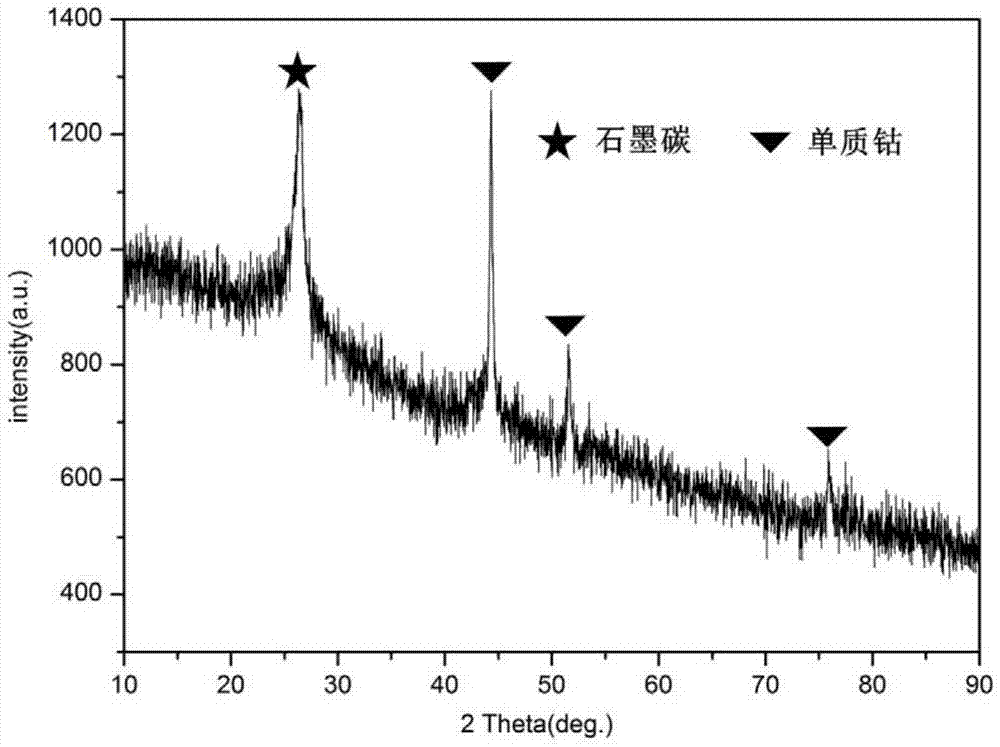

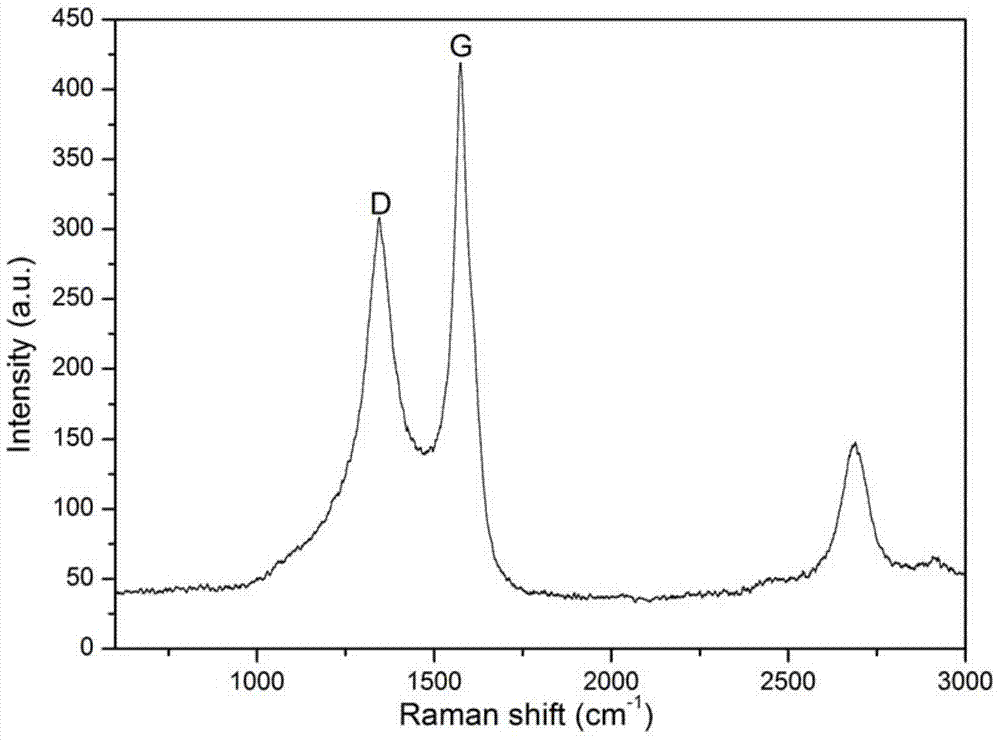

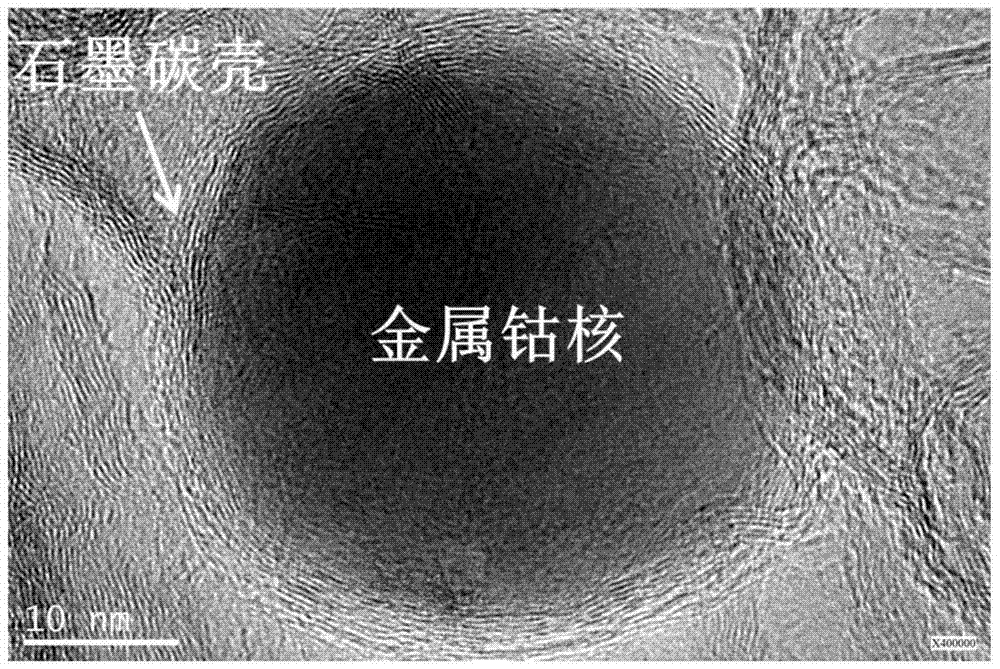

[0032] (1) Weigh 10.09g (120mmol) dicyandiamide (C 2 h 4 N 4 ) and 2.445g (8.4mmol) cobalt nitrate hexahydrate (Co(NO 3 ) 2 ·6H 2O) add in the beaker that contains 300mL methanol solution, continue to stir 20min under the condition of 50 ℃, obtain homogeneous phase clear solution; Obtain homogeneous phase powder after homogeneous phase clear solution is dried, grind; Homogeneous phase powder is placed in quartz tube, Place the quartz tube in the uniform temperature zone of the tubular resistance furnace, raise the temperature to 500°C at a rate of 10°C / min in a nitrogen atmosphere with a flow rate of 0.2mL / min, and keep the temperature constant for 2 hours; then raise the temperature to 700°C, and keep the temperature for 2 hours. hour; after the reaction was finished, the quartz tube was cooled to room temperature in a nitrogen atmosphere to obtain a black powder;

[0033] (2) Put the black powder obtained in step (1) into a beaker, add 300mL of 0.5mol / L sulfuric acid so...

Embodiment 2

[0040] The preparation method of this embodiment is the same as that of Example 1, the only difference is that the water-soluble metal M 2+ Salt selection 1.670g (8.4mmol) ferrous chloride tetrahydrate (FeCl 2 4H 2 O) to replace cobalt nitrate hexahydrate (Co(NO 3 ) 2 ·6H 2 O), obtained nitrogen-doped carbon-coated iron nanoparticles magnetic composite material.

[0041] The mass of the composite material obtained in this example is ~1.6 g, and the doping rate of nitrogen is ~8%.

[0042] Figure 6 For the XRD diffraction pattern of the nitrogen-doped carbon-coated iron nanoparticle magnetic composite material prepared in this example, it can be seen from the figure that the diffraction peak corresponding to 26 ° is graphite carbon, and the remaining three diffraction peaks correspond to simple substance Iron; there are no other diffraction peaks in the spectrum, indicating that the composite material is of high purity without any impurities.

[0043] Figure 7 The XPS...

Embodiment 3

[0045] The preparation method of this embodiment is the same as that of Example 1, the only difference is that the water-soluble metal M 2+ Salt selection 1.997g (8.4mmol) nickel chloride hexahydrate (NiCl 2 ·6H 2 O) to replace cobalt nitrate hexahydrate (Co(NO 3 ) 2 ·6H 2 O) to prepare nitrogen-doped carbon-coated nickel nanoparticle magnetic composite material.

[0046] The mass of the composite material prepared in this embodiment is ~1.3g, and the doping rate of nitrogen is ~7%.

[0047] Figure 8 For the XRD diffraction pattern of the nitrogen-doped carbon-coated nickel nanoparticle magnetic composite material prepared in this example, it can be seen from the figure that the diffraction peak corresponding to 26 ° is graphite carbon, and the remaining three diffraction peaks correspond to simple substance Nickel; there are no other diffraction peaks in the spectrum, indicating that the composite material is of high purity without any impurities.

[0048] Figure 9 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com