Multi-cutter-location numerical control milling machine

A CNC milling machine, multi-tool technology, applied in the field of mechanical processing, can solve problems such as unreasonable cooling mechanism setting, overheating and scrapping of workpieces, equipment failures, etc., achieve stable and smooth tool changing actions, improve work safety, and prolong service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with specific embodiment and accompanying drawing, the present invention will be further described:

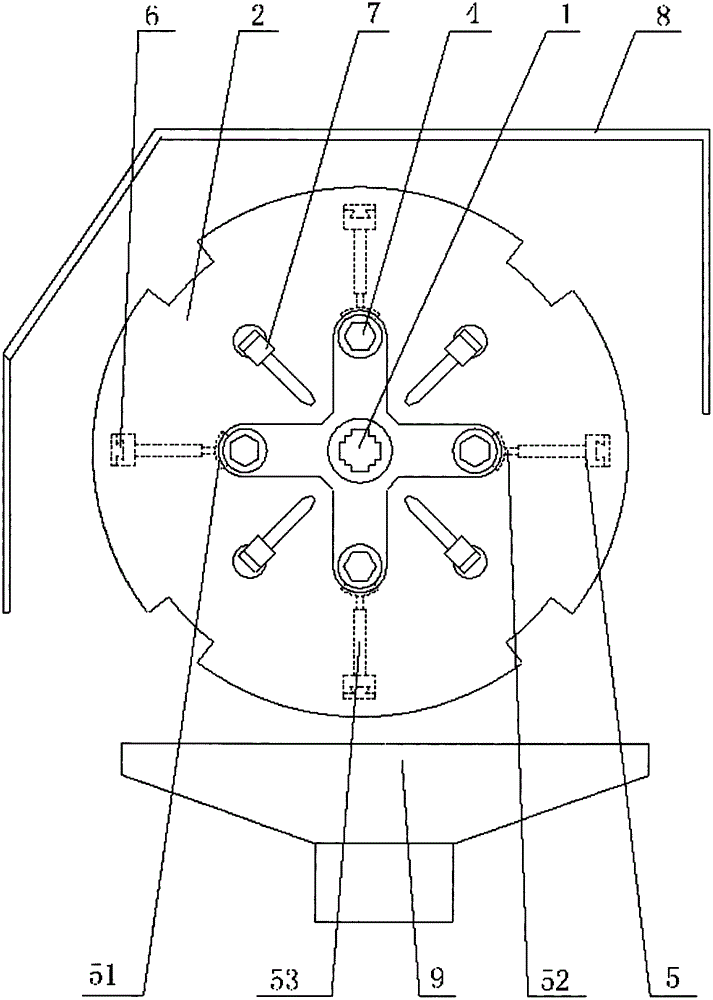

[0018] Refer to attached figure 1 As shown, the multi-cutter CNC milling machine of the present invention includes a workpiece clamping mechanism and a tool clamping mechanism, the workpiece clamping mechanism is provided with a feed drive mechanism, the tool clamping mechanism is provided with a displacement drive mechanism, and the tool clamping mechanism includes a positioning The shaft 1 and the positioning shaft are also equipped with a rotary drive mechanism; the positioning shaft 1 is equipped with a tool disc 2 through a bearing movable sleeve, and the tool disc 2 has at least two tool movable grooves 3, and the tool 4 is arranged on the tool movable slot along the axial direction of the tool disc. In the groove, the tool 2 includes at least two groups of milling cutters with different cutter heads, wherein at least one group of milling cutt...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap