Sport ball gliding press

A ball hot stamping machine and motion technology, applied in printing, printing process, gold powder printing and other directions, can solve the problems of troublesome template operation, large temperature error, large positioning error, etc., to save power, reduce power consumption, and reduce energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

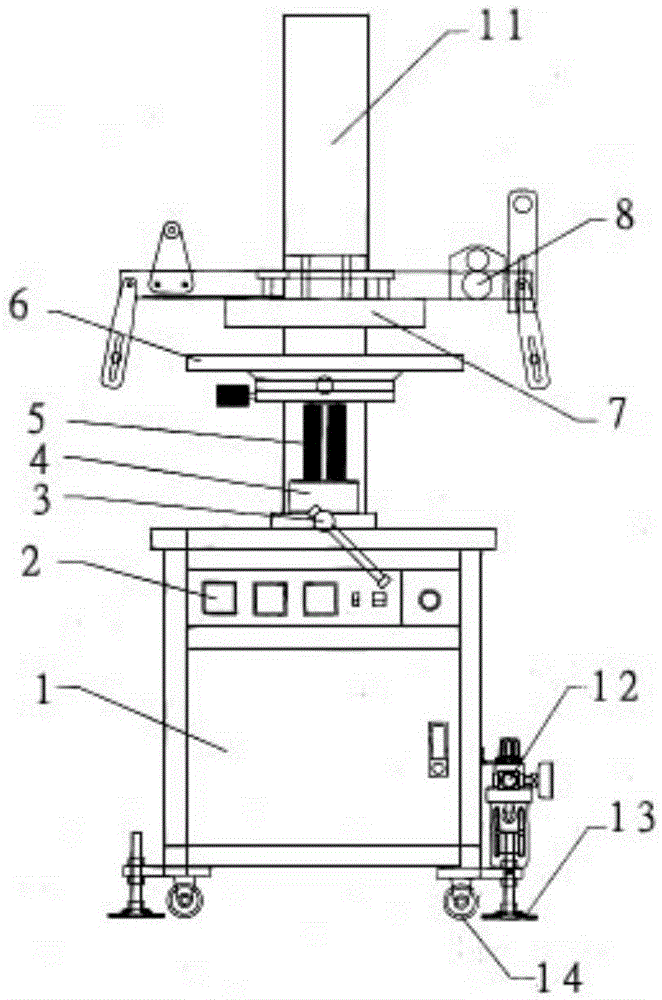

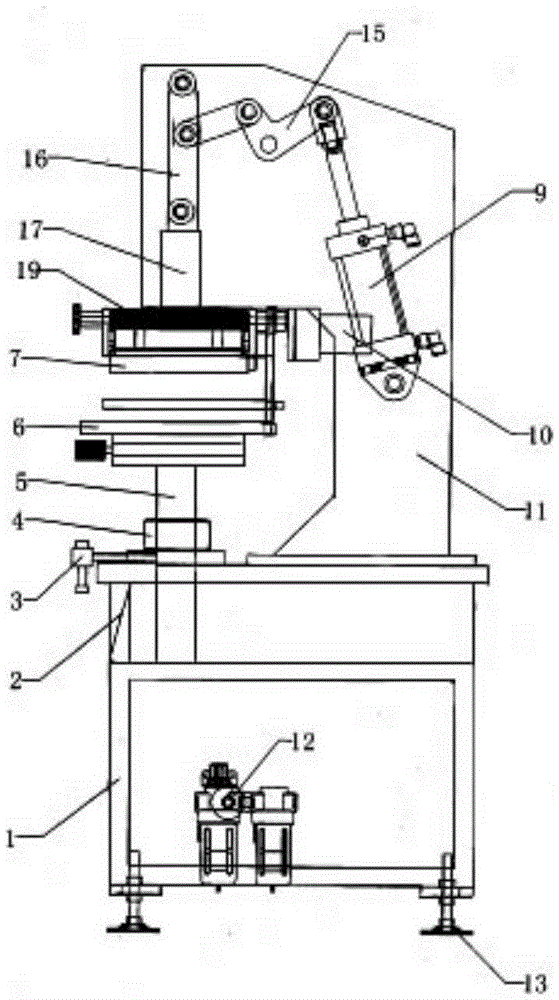

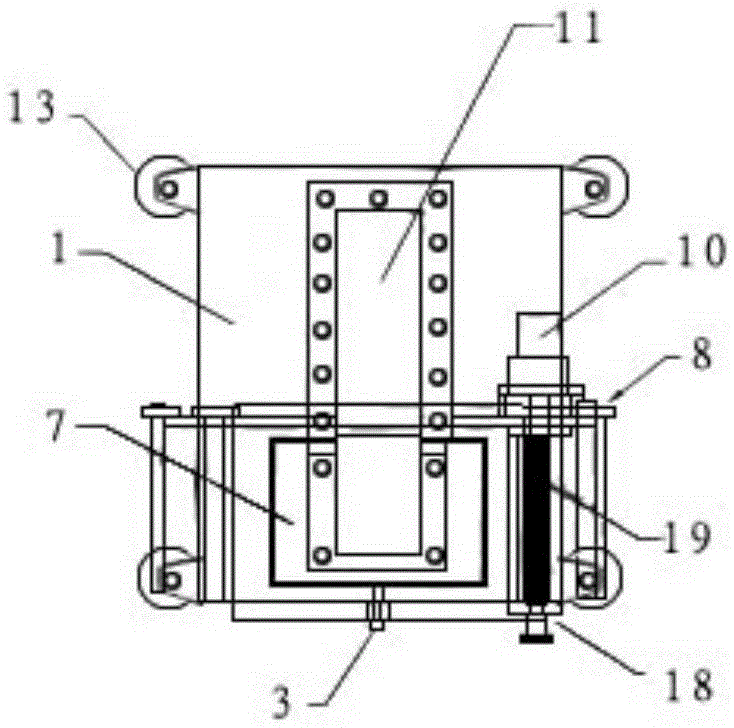

[0013] A sports ball hot stamping machine of the present invention will be further described below in conjunction with the accompanying drawings of the description.

[0014] see figure 1 , figure 2 and image 3 , a sports ball hot stamping machine of the present invention includes a support 1, an operating table 6 and a heating device, a control panel 2 is installed on the front end of the support 1, an air filter 12 is installed on the side of the support 1, and the support 1 The bottom end of the bottom corner wheel 14 and the bottom corner plate 13 are installed, and the top of the support 1 is equipped with a vertical frame body 11. The drive device 9, the output end of the drive device 9 is sequentially connected to the adjustment shaft 15 and several transmission shafts 16 of different specifications, the bottom of the transmission shaft 16 is connected to a pulley 17, and the bottom of the pulley 17 is connected to the heating device, which includes a heating furnace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com