A kind of yttrium-based rare earth low-alloy high-strength steel and its manufacturing method

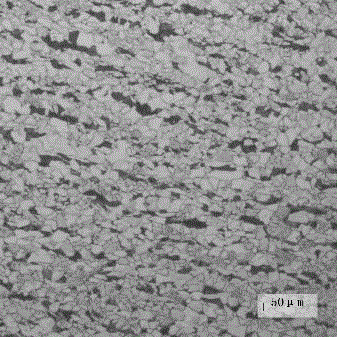

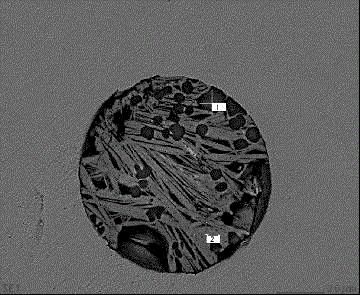

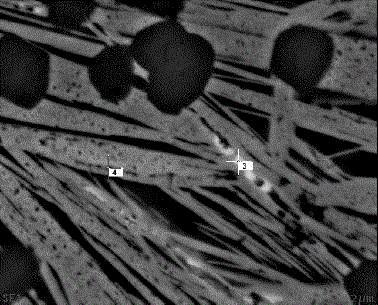

A low-alloy, high-strength, manufacturing method technology, applied in the direction of improving process efficiency, can solve the problems of limited improvement of banded structure, affecting the pass rate of steel performance, and limited improvement, so as to reduce the interlayer spacing of pearlite and inhibit Pearlite volume, effect of reducing impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0039] See Table 2 for the composition of the steel produced by the yttrium-based rare earth low-alloy high-strength steel and the manufacturing method of the present invention.

[0040] Table 2 Yttrium-based rare earth treated steel composition, wt%

[0041] Grade C mn Si P S Cr Ni Cu Mo V Ti Alt Nb N Y Ce CCSEH36 0.13 1.20 0.21 0.021 0.003 0.07 0.04 0.05 0.002 0.003 0.011 0.023 0.017 0.006 0.006 0.023 Q345GJB 0.14 1.42 0.30 0.020 0.010 0.03 0.05 0.06 0.005 0.08 0.012 0.023 0.025 0.009 0.009 0.020 Q345qC 0.13 1.50 0.31 0.018 0.009 0.04 0.04 0.05 0.005 0.06 0.015 0.030 0.028 0.008 0.008 0.019 Q370qE 0.16 1.46 0.22 0.010 0.005 0.03 0.03 0.04 0.004 0.07 0.014 0.028 0.032 0.008 0.010 0.018 Q345B 0.18 1.58 0.30 0.025 0.023 0.04 0.04 0.06 0.005 0.05 0.003 0.005 0.001 0.011 0.007 0.016 Q390C 0.15 1.51 0.34 0.015 0.008 0.05 0.05 0.05 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com