Method and equipment for preparing multi-layer composite material and structural damping composite material

A multi-layer composite material and composite material technology, applied in the field of structural damping composite materials, can solve problems such as poor bonding between damping materials and structural materials, easy damage to interlayer structures, difficulty in eliminating noise and vibration pollution and hazards, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

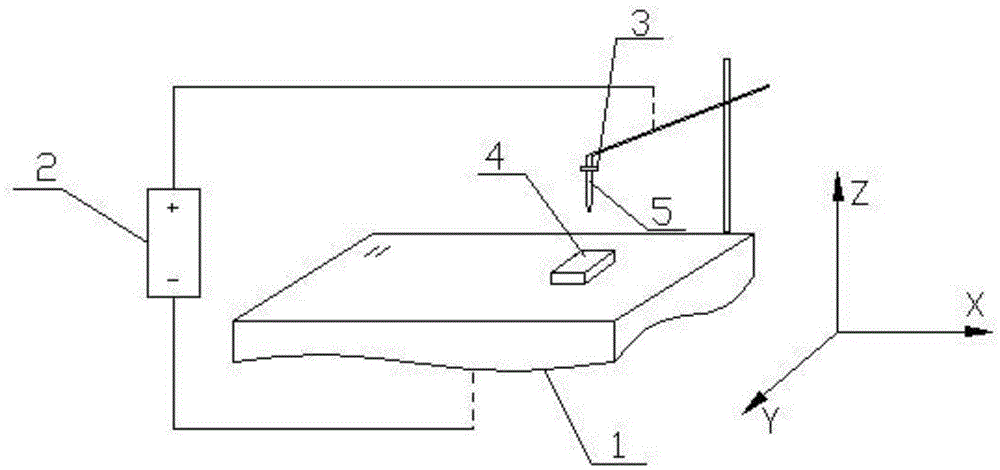

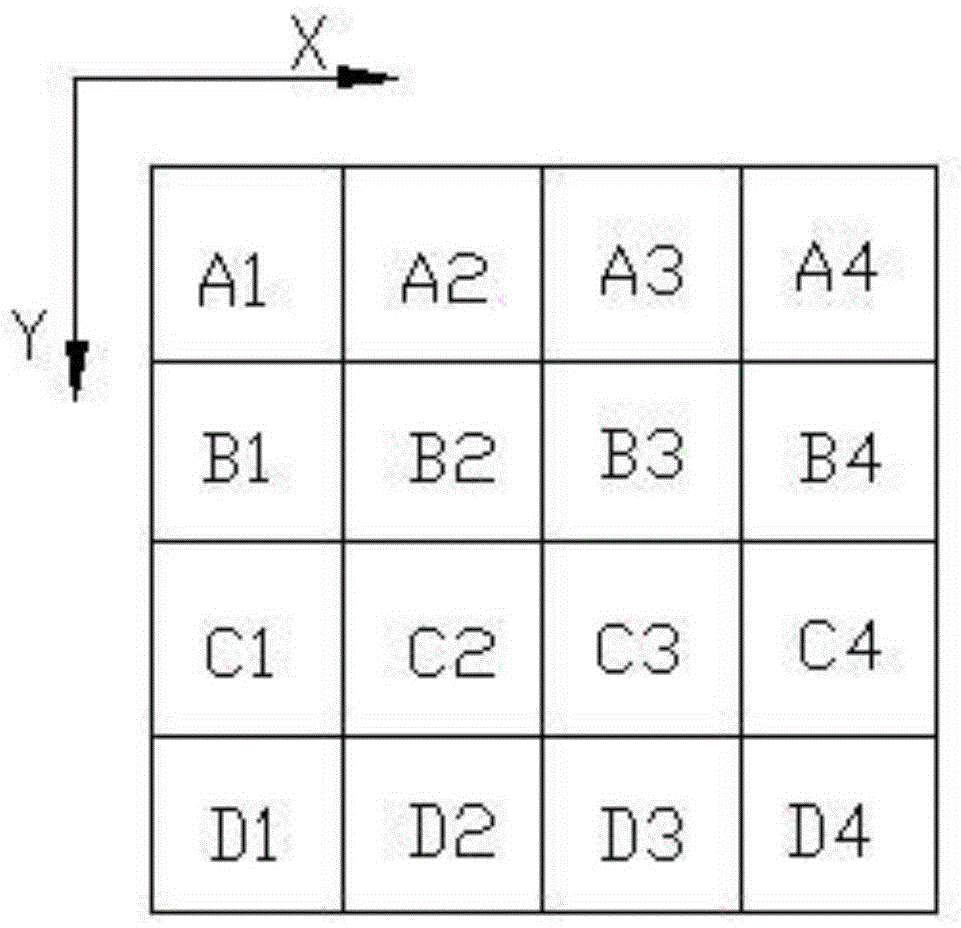

[0020]The multilayer composite material in this embodiment is a structural damping composite material with 316 type alloy steel as the matrix layer, Zn-Al alloy as the first damping layer and Fe-Cr alloy as the second damping layer, the first damping layer and the source of the second damping layer are Zn-Al alloy electrode and Fe-Cr alloy electrode respectively, wherein, each component and its content in Zn-Al alloy are Al20wt%, Cu5wt%, Mg0.1wt%, the rest It is Zn; each component and its content in the Fe-Cr alloy are Cr10wt%, Al5wt%, Si2wt%, and the rest is Fe. The area required for deposition in this embodiment is figure 2 The grids of A1-A4 and B1-B4 are prepared as follows:

[0021] use as figure 1 In the shown equipment, the 316-type alloy steel 4 is placed on the workbench 1 and connected to the cathode of the pulse power supply 2, and then the electrode clamping part 3 connected to the anode of the pulse power supply 2 clamps the Zn-Al alloy electrode ( The first e...

Embodiment 2

[0025] The multilayer composite material in this embodiment is a structural damping composite material with 304 type alloy steel as the matrix layer, Fe-Cr alloy as the first damping layer and Zn-Al alloy as the second damping layer, the first damping layer and the source of the second damping layer are Fe-Cr alloy electrode and Zn-Al alloy electrode respectively, wherein, each component and its content in Zn-Al alloy are Al24wt%, Cu4wt%, Mg0.06wt%, the rest It is Zn; each component and its content in the Fe-Cr alloy are Cr16wt%, Al4wt%, Si0.6wt%, and the rest is Fe. The area required for deposition in this embodiment is figure 2 The grid of A1-A4 in the grid, its preparation process is as follows:

[0026] use as figure 1 In the shown equipment, 304-type alloy steel 4 is placed on the workbench 1 and connected to the cathode of the pulse power supply 2, and then the electrode clamping part 3 connected to the anode of the pulse power supply 2 clamps the Fe-Cr alloy electrod...

Embodiment 3

[0030] The multilayer composite material in this embodiment is a structural damping material with aluminum alloy as the matrix layer, Zn-Al alloy as the first damping layer and Fe-Cr alloy as the second damping layer, the first damping layer and the second The source of the damping layer is a Zn-Al alloy electrode and a Fe-Cr alloy electrode, wherein the components and their contents in the Zn-Al alloy are Al27wt%, Cu2wt%, Mg0.04wt%, and the rest is Zn; Each component and its content in the Fe-Cr alloy are 12.75wt% Cr, 1.97wt% Al, 1.1wt% Si, and the rest is Fe. The area required for deposition in this application is figure 2 For all grids in , the preparation process is as follows:

[0031] use as figure 1 In the shown equipment, the aluminum alloy 4 is placed on the workbench 1 and connected to the cathode of the pulse power supply 2, and then the electrode clamping part 3 connected to the anode of the pulse power supply 2 clamps the Zn-Al alloy electrode (the first elect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pulse width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com