Optimization method for impeller hydraulic power of normal residual heat removal pump used for nuclear power plant

A waste heat discharge pump and hydraulic optimization technology, applied in the field of nuclear power, can solve the problems of long cycle, heavy workload, high cost, etc., and achieve the effect of reducing optimization cost, reducing workload, and good economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing, the present invention is further described, but not as limitation of the present invention:

[0026] as attached Figure 4 As shown in the figure, an impeller hydraulic optimization method for a normal waste heat discharge pump used in a nuclear power plant is characterized in that it includes the following optimization steps:

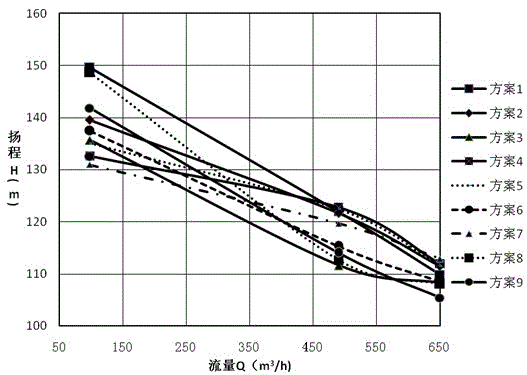

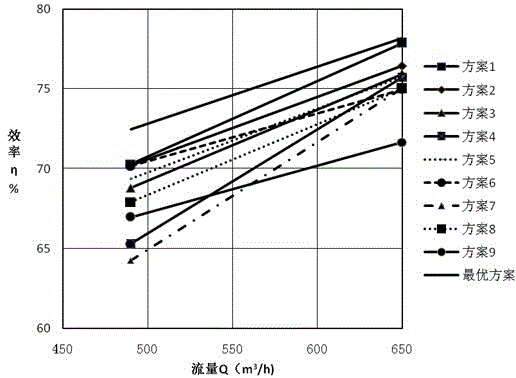

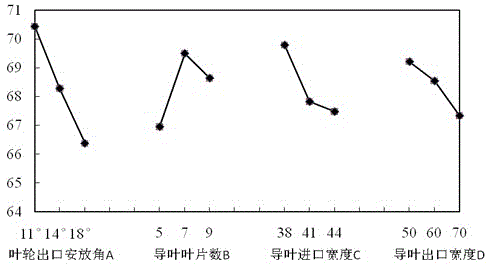

[0027] 1) Determining the objective function: First, make a preliminary hydraulic design for the impeller and guide vane of the hydraulic components of the normal waste heat discharge pump through the empirical design method, and use the Fluent software to carry out numerical simulation of the hydraulic power, and obtain the numerical simulation results, the pump head has been meet the requirements, but the efficiency does not meet the requirements of the specification, and the highest efficiency point shifts to the large flow, so the pump efficiency is selected as the objective function of the opt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com