Clogging device for casting furnaces for aluminum products

A technology for aluminum products and furnaces, applied in the production field of aluminum products, can solve the problems of time-consuming and laborious operation of furnace eye blockage, and achieve the effect of saving time and labor, simple operation and increasing contact area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

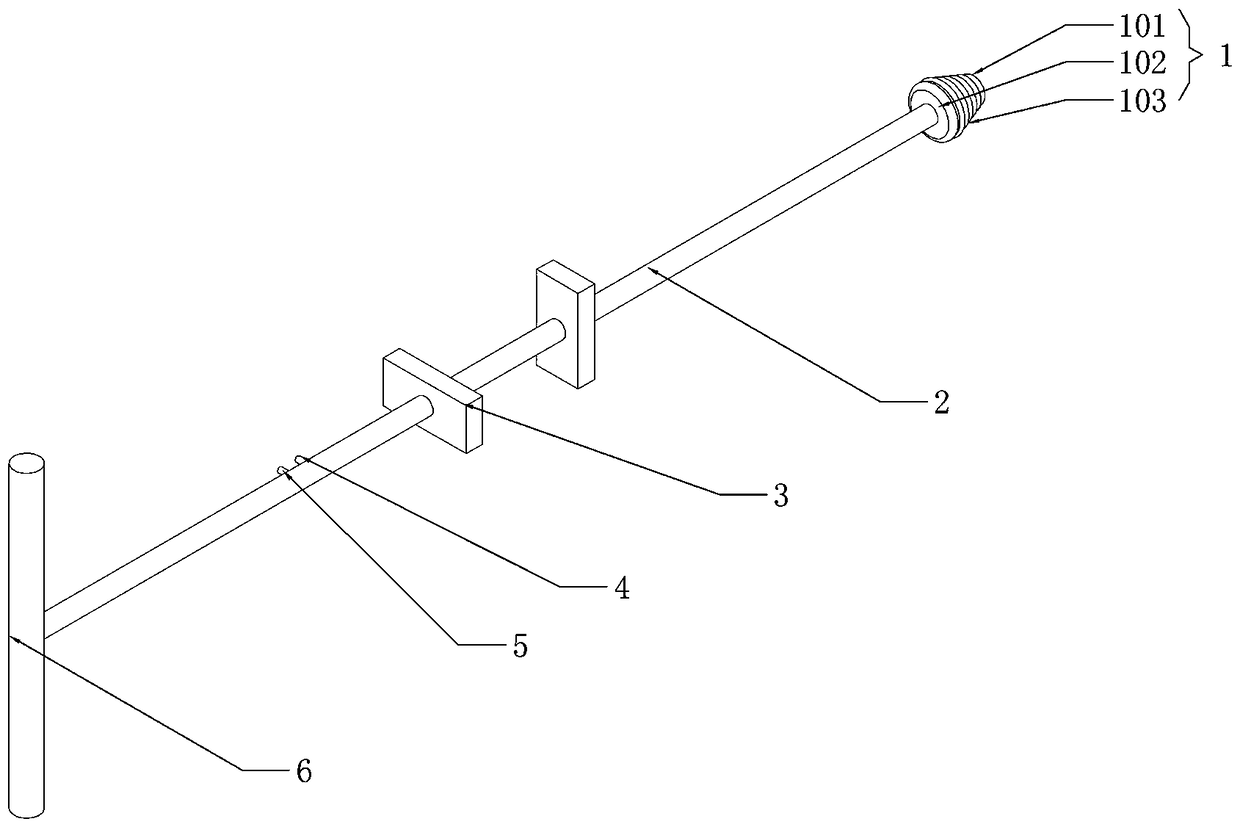

[0016] Embodiment 1: as attached figure 1 As shown, the plugging device for casting furnaces for aluminum products includes a long rod 2 and a plug head 1. The plug head 1 includes a top 101 and a plug body 102. The surface of the plug body 102 has several circles of round threads whose diameter gradually decreases toward the top 101. 103, the diameter ratio between adjacent round threads 103 is 1:1.2; the long rod 2 and the plug body 102 are hollow structures, with cooling water circulation pipes inside, and the middle part of the long rod 2 is on the rod on the same side There is a water inlet pipe 4 and an outlet pipe 5 connected to the cooling water circulation pipeline; the middle part of the long rod 2 is welded with a striking plate 3, and the end of the long rod 2 is provided with a support rod 6 whose length is greater than the width of the chute. 101 is an arc surface.

Embodiment 2

[0017] The difference between embodiment 2 and embodiment 1 is that the diameter ratio between adjacent circular threads 103 is 1:1.5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com