High-precision measurement device and measurement method for angle of pitch

A technology of measuring device and pitch axis, which is applied in the directions of measuring device, measuring angle, surveying and mapping, and navigation, etc., can solve the problem that the accuracy level operation convenience cannot meet the requirements of pitch angle measurement of two-dimensional turntable, and the difficulty of high-precision measurement of two-dimensional turntable, The detection method cannot be realized, etc., to achieve the effect of automatic testing and result recording and output, simple and fast installation and placement of instruments, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

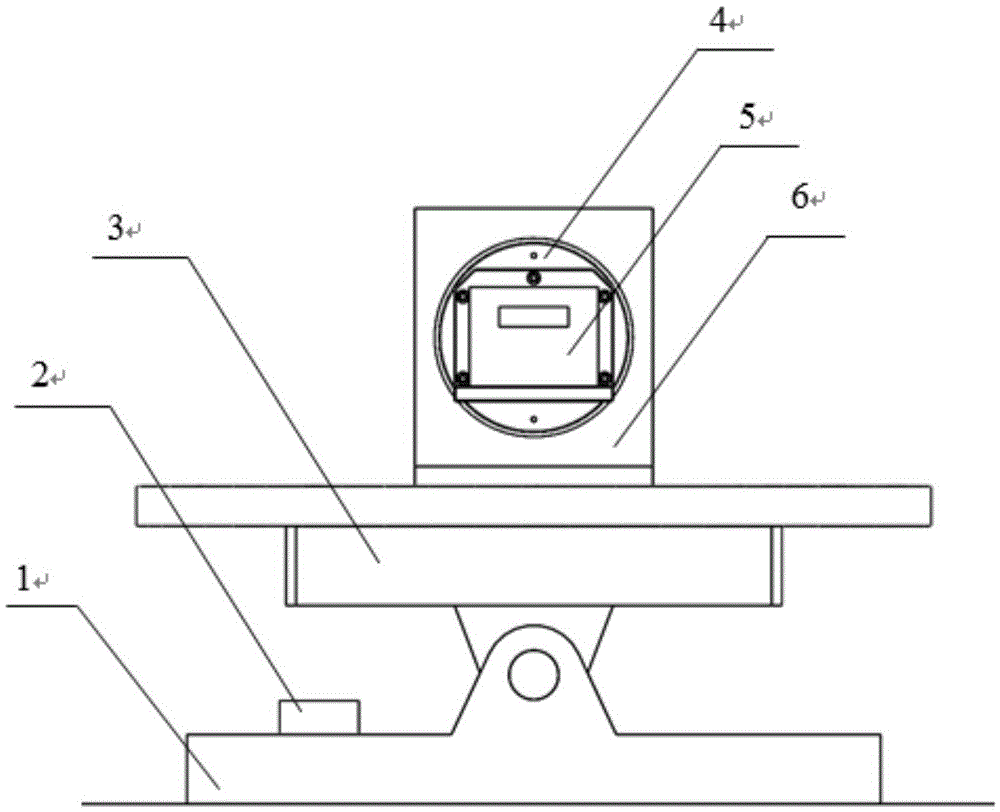

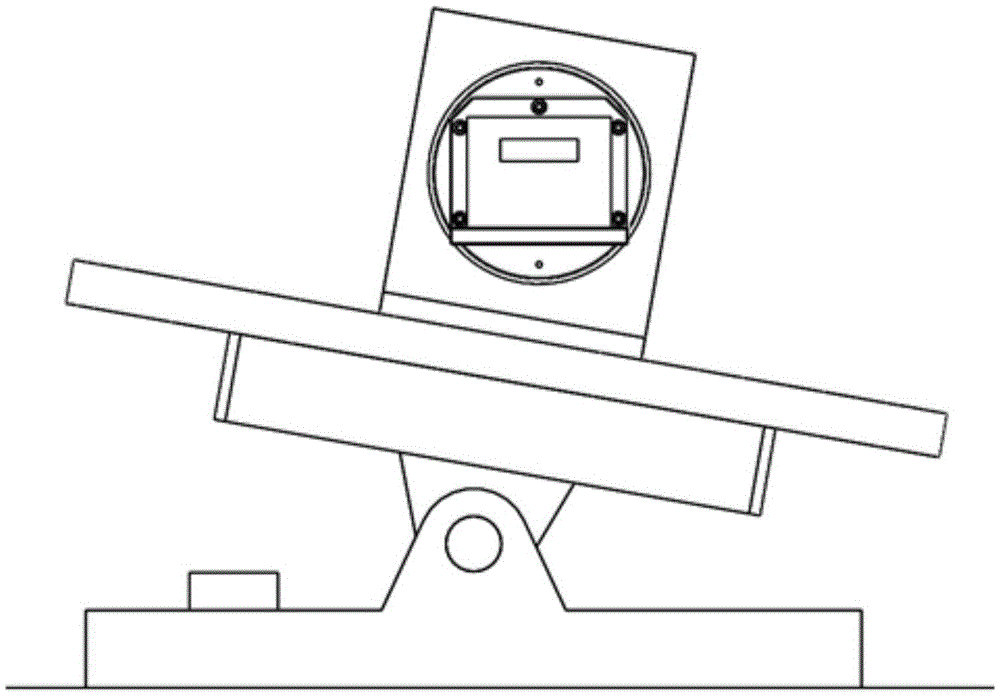

[0033] In this scheme, the pitch angle high-precision measuring device is composed of a horizontal multi-tooth indexing platform and a high-precision electronic level, see figure 1 . The two-dimensional turntable base 1 is fixed with a high-precision electronic level 2 for additional compensation, and the two-dimensional turntable pitch axis moving table 3 is axially connected to the two-dimensional turntable base 1 . The horizontal multi-tooth indexing table 4 has a horizontal multi-tooth indexing table base 6, and the high-precision electronic level 5 is located in the center of the multi-tooth indexing table.

[0034] When measuring the pitch angle of the turntable, proceed as follows:

[0035] 1. Set the pitch angle of the two-dimensional turntable to zero, so that the plane of the turntable is horizontal.

[0036] 2. Return the position of the horizontal multi-tooth indexing table 4 to zero, and the high-precision electronic level 5 is reliably fixed on the center of th...

Embodiment 2

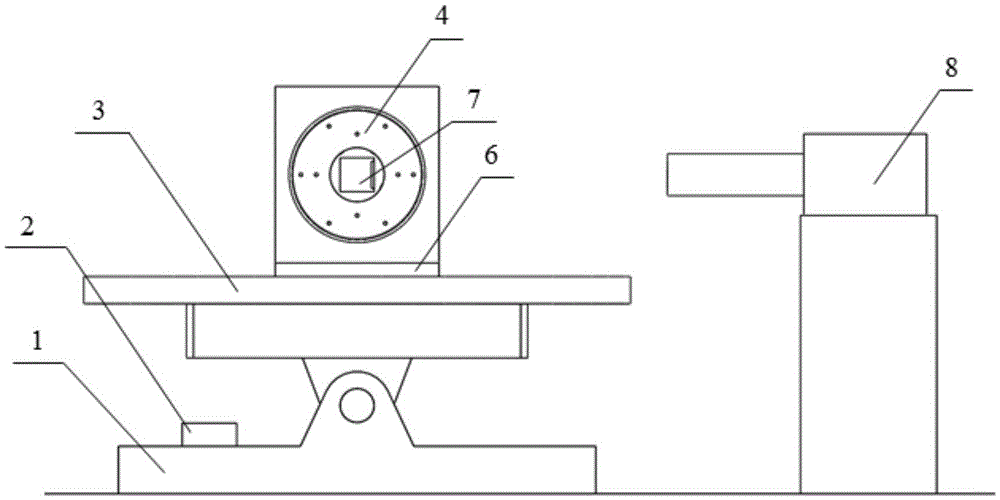

[0044] Measuring system composed of bottom-horizontal multi-tooth indexing table, reflector and high-precision optoelectronic collimator, see image 3 . The two-dimensional turntable base 1 is fixed with a high-precision electronic level 2 for additional compensation, and the two-dimensional turntable pitch axis moving table 3 is axially connected to the two-dimensional turntable base 1 . The horizontal multi-tooth indexing table 4 has a horizontal multi-tooth indexing table base 6, and the plane mirror 7 is located in the center of the multi-tooth indexing table. The high-precision optoelectronic autocollimator 8 is firmly and reliably placed on the side of the same foundation as the two-dimensional turntable base 1 .

[0045] When measuring the pitch angle of the turntable, proceed as follows:

[0046] 1. Set the pitch angle of the two-dimensional turntable to zero, so that the plane of the turntable is horizontal.

[0047] 2. Return the position 4 of the horizontal multi-t...

Embodiment 3

[0055] can also be used as Figure 5 Devices shown: 1. Two-dimensional turntable base; 2. High-precision electronic level for additional compensation; 3. Two-dimensional turntable pitch axis moving table; 4. Horizontal multi-tooth indexing table; 5. High-precision electronic level; 6 , Horizontal multi-tooth indexing table base; 9, electronic level meter pitch angle fine-tuning mechanism; 10, magnetic fixing device; 11, electric control system.

[0056] Its measuring method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com