Photoresist recovery system and method thereof

A technology of photoresist and recovery system, which is applied in the direction of photoplate making process coating equipment, etc., can solve the problems of increased production cost, waste of photoresist liquid, and decreased competitiveness, so as to reduce waste and reduce production cost and reduction in replacement times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Embodiments of the invention are described more fully hereinafter with reference to the accompanying drawings. However, the present invention may be practiced in many different forms and is not limited to the embodiments set forth herein. The directional terms mentioned in the following embodiments, such as "upper", etc., are only referring to the directions of the accompanying drawings, so the directional terms used are for explaining the description rather than limiting the present invention. In addition, the size and relative size of each layer may be exaggerated for the sake of clarity in the drawings.

[0055]Hereinafter, a photoresist recovery system according to an embodiment of the present invention will be described. The embodiments of the present invention are illustrated by taking the application in photoresist coating manufacturing process equipment as an example, but it is not limited thereto.

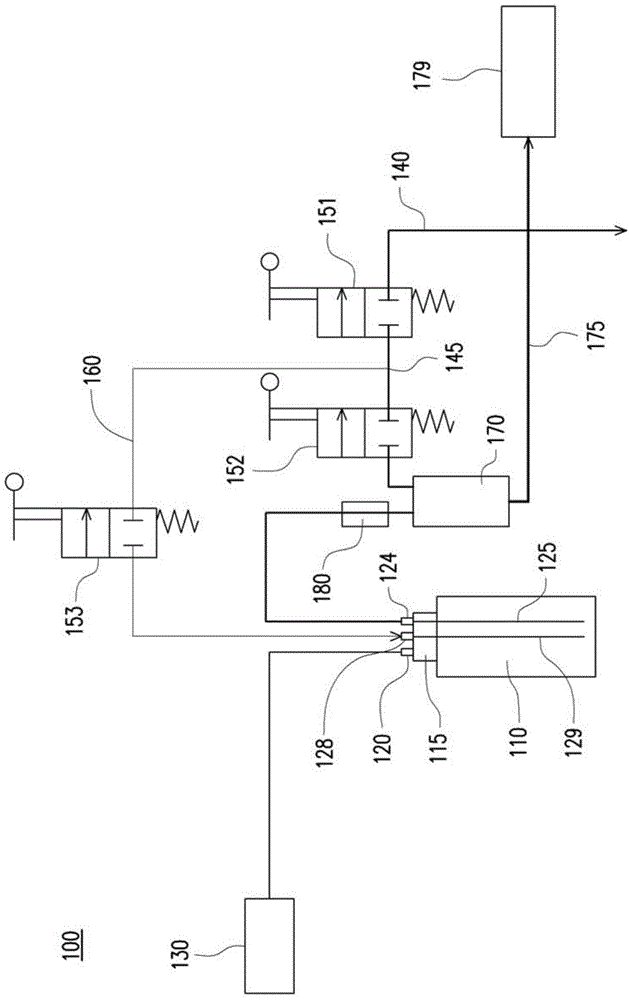

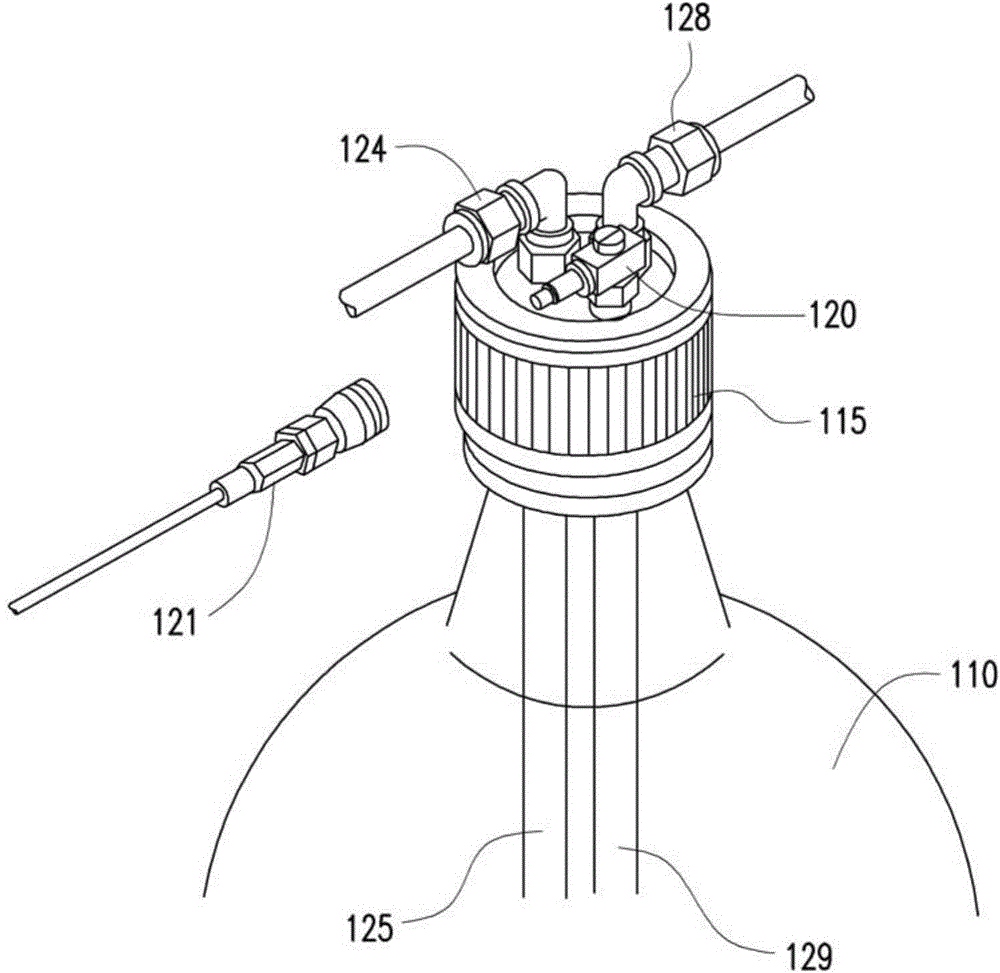

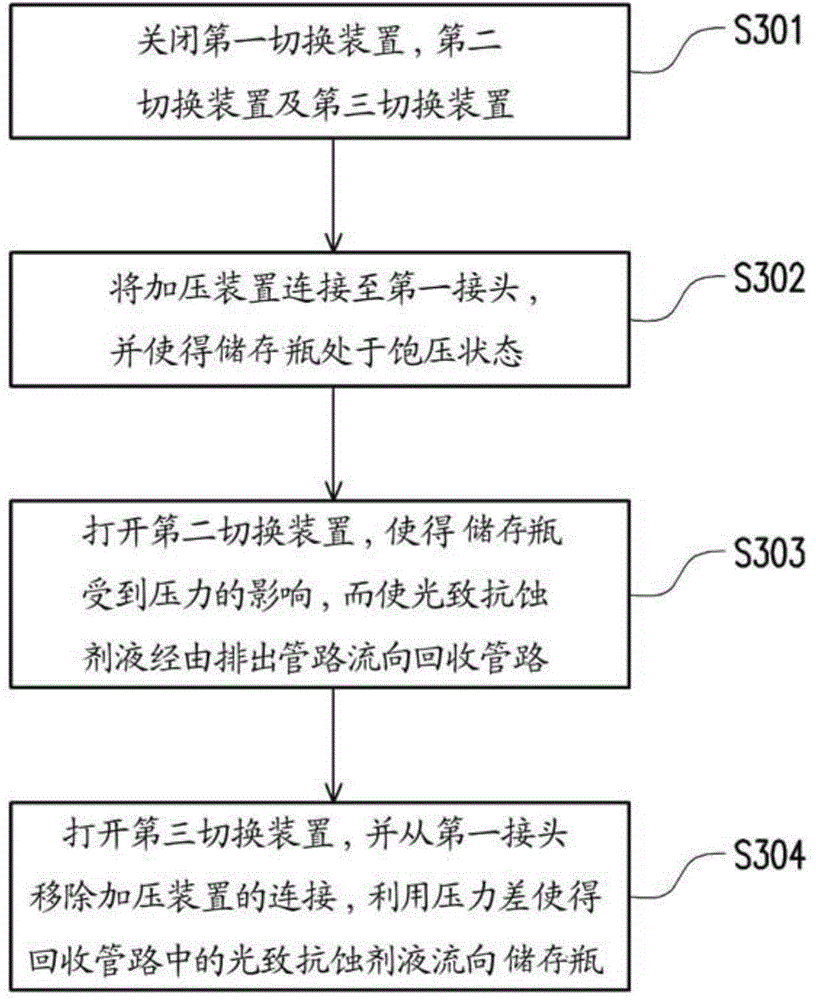

[0056] figure 1 It is a structural configuration diagram of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com