Fuzzy controller of denitrated urea pyrolysis process

A fuzzy controller, urea technology, applied in the direction of adaptive control, general control system, control/regulation system, etc., can solve the problems of insufficient pyrolysis amount and incomplete pyrolysis, achieve stable denitrification efficiency and improve reliability , to avoid the effect of equipment blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

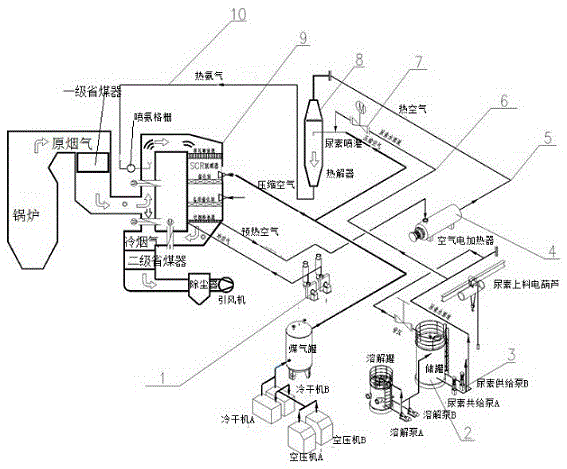

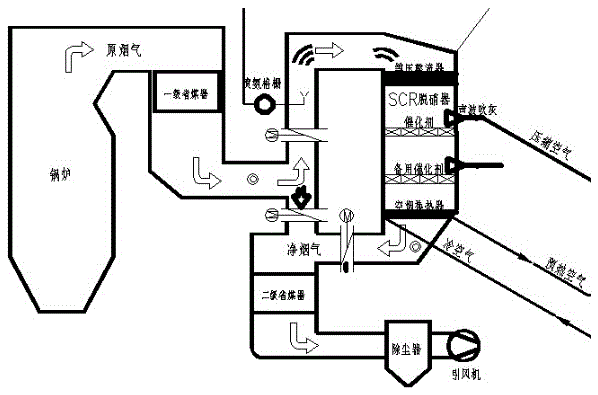

[0028] Embodiment 1: see figure 1 , figure 2 , the urea pyrolysis treatment process is that the urea solution stored in the urea solution storage tank 2 passes through the urea supply pump 3 along the urea solution pipeline 6 , is atomized by the regulating valve 7 , and then enters the urea pyrolysis furnace 8 . The hot air for pyrolysis is transported by the dilution fan 1 to the air heater 4 to be heated to the pyrolysis temperature, and then sent to the urea pyrolysis furnace 8 through the hot air pipeline 5 to mix and pyrolyze the atomized urea droplets. The final hot ammonia gas is sent to the denitrification reactor 9 through the hot ammonia gas pipeline 10 for denitrification reaction to complete the entire process flow, and the flow rate of the urea solution is controlled through the regulating valve 7 to achieve flow matching.

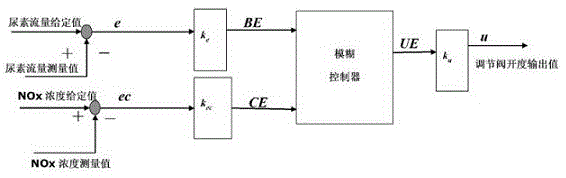

[0029] The existing urea pyrolysis adopts the traditional PID adjustment method, which is a single-loop closed-loop control, and there are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com