Progressive die complex metal plate member stamping process sequence planning method

A technology for process sequence and sheet metal parts, which is applied in the field of process sequence planning for complex sheet metal parts in progressive dies, and can solve problems such as unqualified product quality, complex process design, and cumbersome calculations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0082] 1. Identify the features of sheet metal parts:

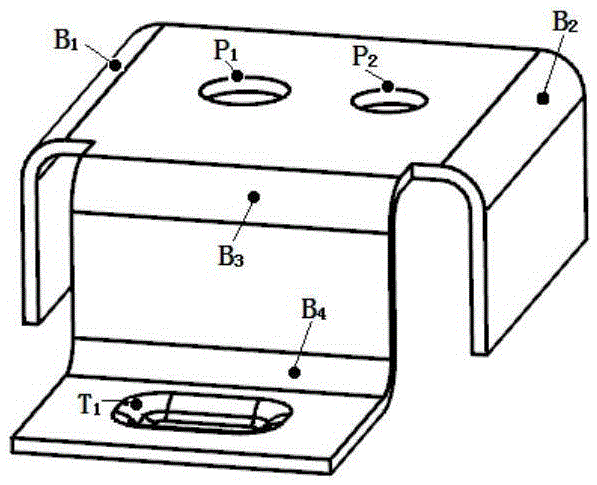

[0083] Typical features of sheet metal parts include punching, shearing, bending, stretching, local forming, etc., such as figure 1 The basic features of the sheet metal part shown are: 4 bending features B1, B2, B3, B4, 2 punching holes P1, P2, and 1 local forming feature T1.

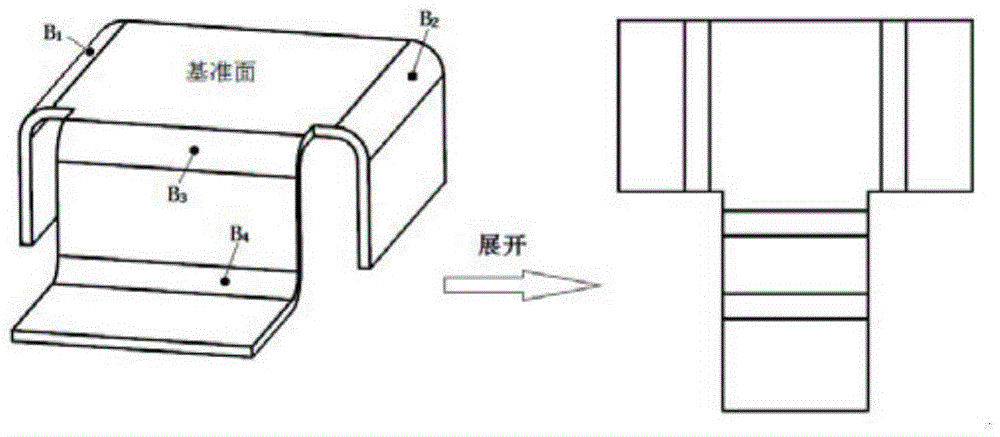

[0084] 2. Bending and unfolding, generating layout features:

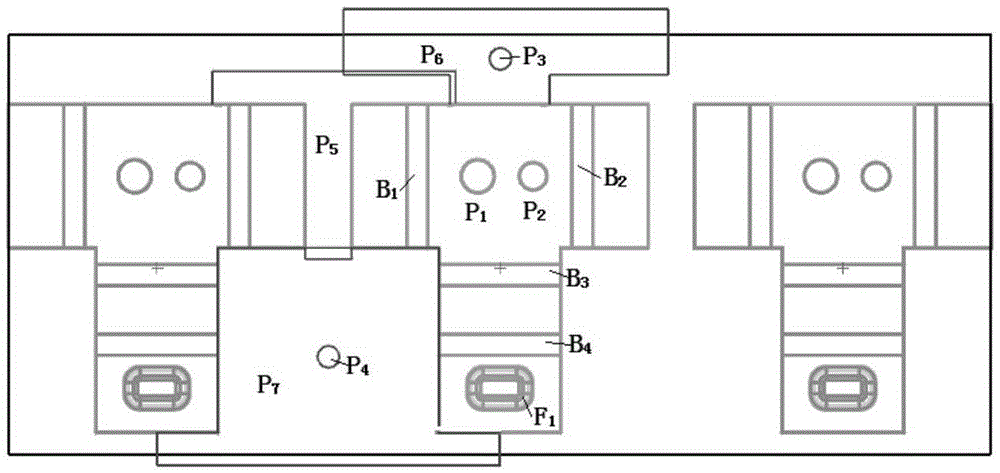

[0085] refer to figure 2 As shown, the sheet metal parts are unfolded, laid out on the strip, and the waste design is carried out, among which punching type: punching P1, punching P2, punching P3, punching P4; blanking type: blanking P5, blanking Material P6, blanking P7; Bending type: Bending B1, Bending B2, Bending B3, Bending B4; Forming type: F1, the position of all features such as image 3 shown.

[0086] 3. Generate sequence planning matrix

[0087] Generate an operation priority matrix according to the process layout rules, and define different sizes of weights on differen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com