Diesel low-exhaust-temperature fault prediction system and method

A technology of fault prediction and prediction method, which is applied in the direction of test/monitoring control system, general control system, control/regulation system, etc. It can solve the problems of high degree of component correlation, complex diesel engine structure, and no fault prediction yet, and achieve compatibility. Strong and efficient handling of faults

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

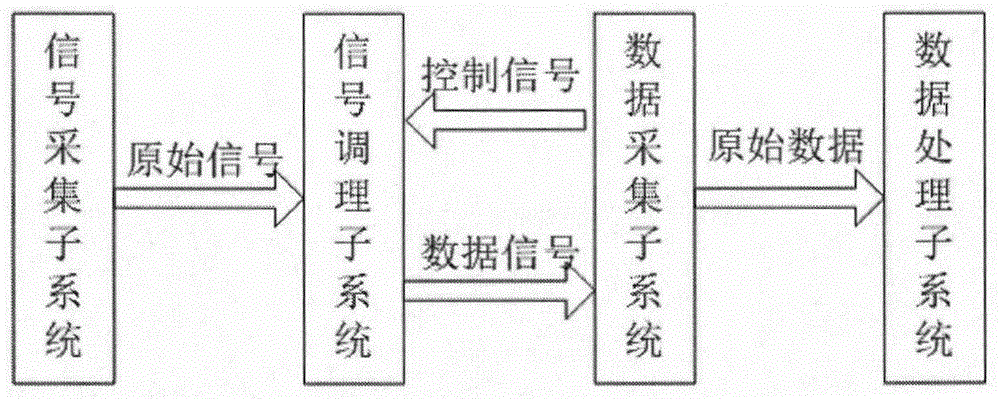

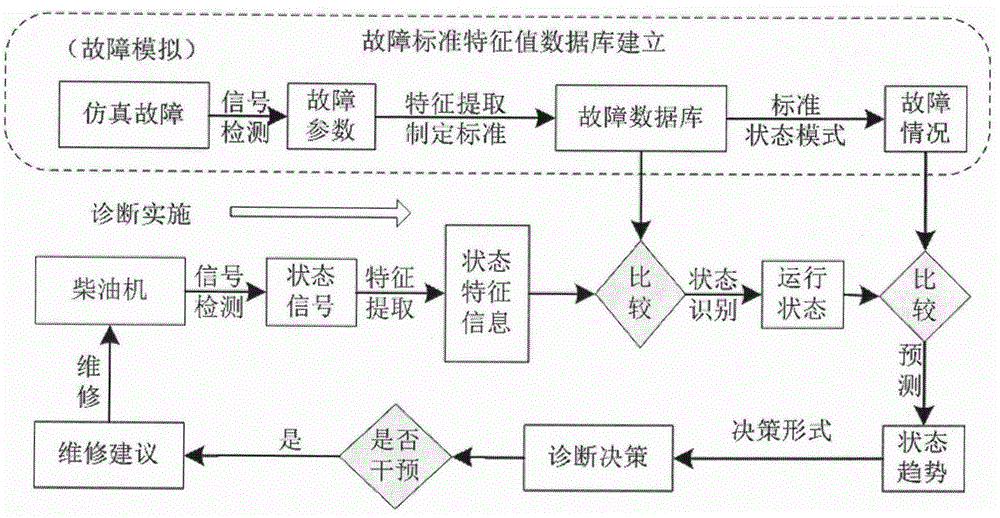

[0029] A low exhaust temperature fault prediction system for a diesel engine, including a signal acquisition system, a modeling simulation system, and a fault diagnosis system connected in sequence; the signal acquisition system is used to collect signals on the diesel engine, process them, and transmit the signals to a monitoring computer storage and processing; it includes four subsystems of signal acquisition, signal conditioning, data acquisition and data processing; the signal acquisition subsystem includes sensors to extract the original signal of the diesel engine, and the acquisition frequency of the signal is once every 1 second; The conditioning subsystem performs system filtering, range adjustment, signal conversion, and signal amplification processing on the original signal; the data acquisition subsystem performs A / D conversion on the signal, and converts the power signal output by the signal conditioning subsystem into a value for the next step data Processing and...

Embodiment 2

[0031] A method for predicting a low exhaust temperature fault system of a diesel engine, comprising the following steps:

[0032]Step 1, the signal acquisition system directly extracts and processes the original signal of the diesel engine, and transmits the signal to the monitoring computer for storage and processing; it uses PHP scripting language to write software, and reads the relevant parameters of the diesel engine in the SQLServer database every 1 second And record it in the txt file, analyze the relevant parameters in the file, remove the distortion points in the data, and perform smoothing processing; the signal acquisition system includes four subsystems: signal acquisition, signal conditioning, data acquisition and data processing, and the signal acquisition sub-system The system is mainly composed of sensors, which directly extract the original signal of the diesel engine; the signal conditioning subsystem performs system filtering, range adjustment, signal conver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com