Prediction method for normalized fatigue delamination propagation rate of CFRP (carbon fiber-reinforced plastic) multi-directional laminated plate

A technology of expansion rate and prediction method, which is applied in the field of prediction of fatigue delamination expansion rate of CFRP multi-directional laminates, can solve the problems that the fatigue delamination expansion rate cannot be estimated, the test period is long, and has not yet been proposed, so as to shorten the test workload, The effect of reducing test cost and good consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention is described in further detail below in conjunction with embodiment.

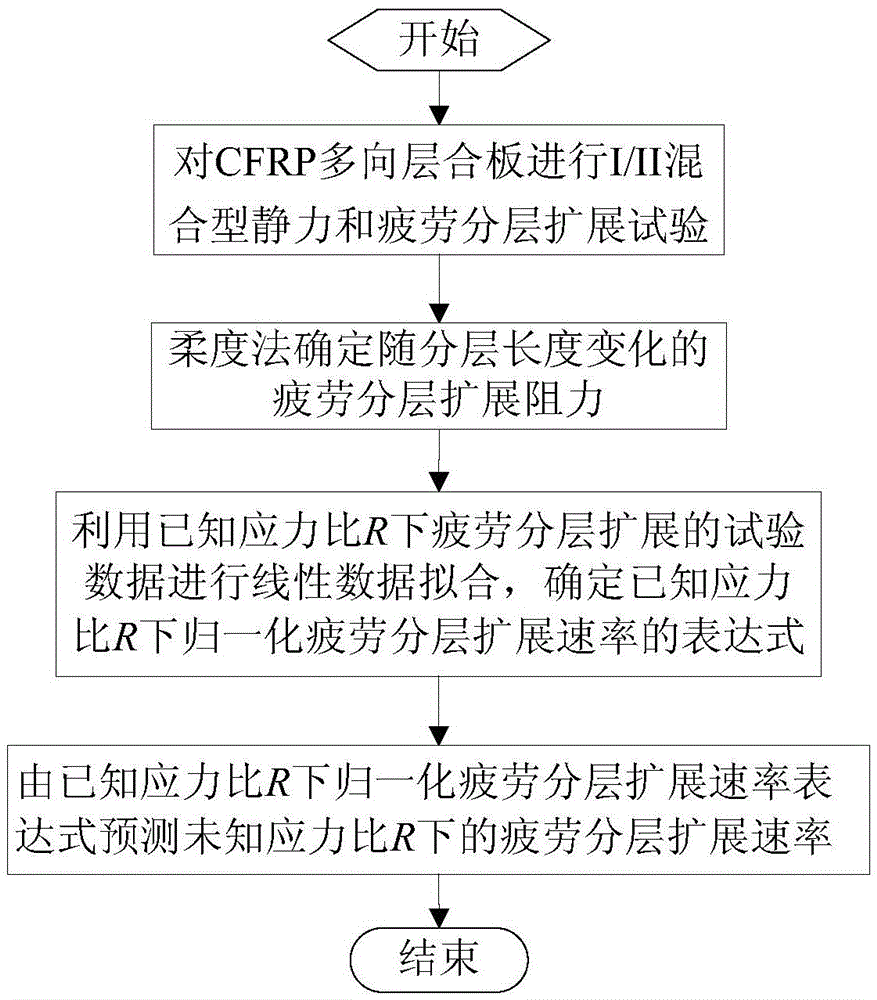

[0032] A method for predicting the fatigue delamination expansion rate of a normalized CFRP multidirectional laminate in the present invention, the specific implementation steps are as follows:

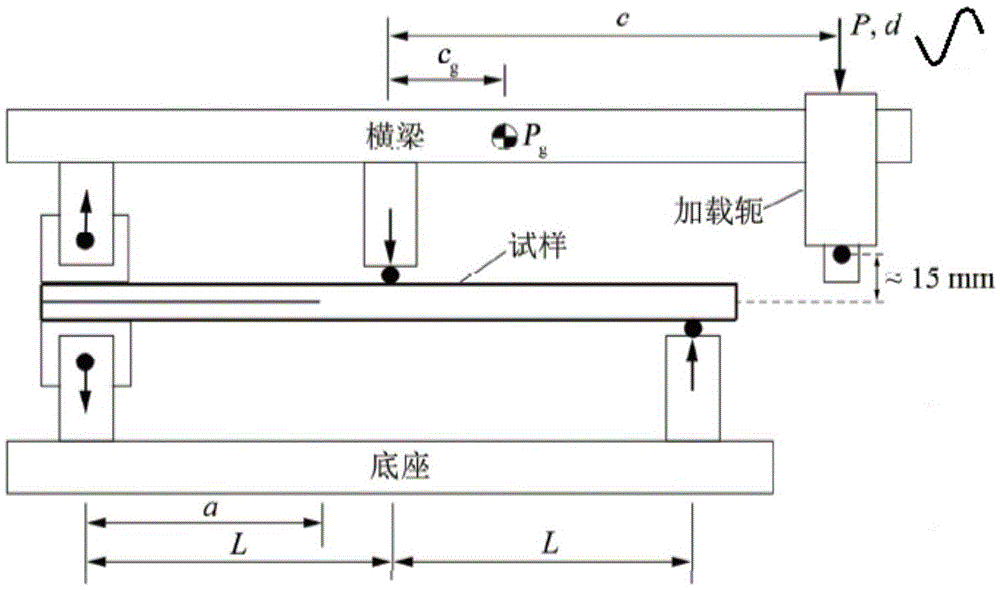

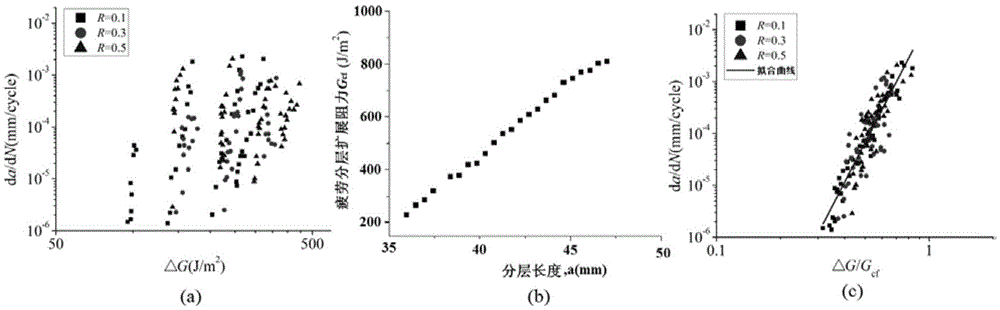

[0033] Step 1: According to ASTM standard D6671M-06 for unidirectional prepreg made of T700 / 9511 carbon fiber / bismaleimide resin system, the layup sequence is (+45 / -45 / 06) S / / (-45 / +45 / 06) S Mixing ratio of CFRP multidirectional laminates Type I / II Hybrid Static Delamination Expansion Test, and the Mixing Ratio Under the fatigue layered extension test. Among them, fatigue delamination expansion tests under three different stress ratios R=0.1, R=0.3 and R=0.5 were carried out respectively. The test loading scheme is as follows figure 2 As shown, the mixing ratio required for the test can be achieved by adjusting the distance c between the loading point and the middle section of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com