Permanent magnet material containing multiple rare earth phases and preparation method

A permanent magnet material and rare earth technology, applied in the fields of magnetic materials, inorganic material magnetism, metal material coating technology, etc., can solve the problem of insufficient magnetic energy product, and achieve the effect of improving the environment, high social value, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

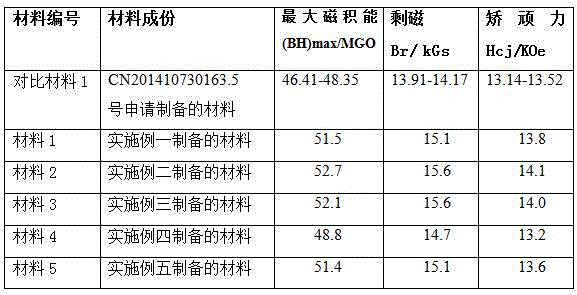

Examples

Embodiment 1

[0037] The preparation method of multi-rare earth phase permanent magnet material of the present invention, the method comprises the steps:

[0038] 1) Waste disposal:

[0039] a) Take NdFeB permanent magnet waste with a mass fraction of 15% Na 2 CO 3 solution to remove oil from waste, Na 2 CO 3 The mass ratio of waste to waste is 0.03:1. After the treated waste is filtered and washed 3 times, it is dried in an oven at 125°C for 2 hours to obtain deoiled waste; then the deoiled waste is placed in a concentration of 30% In the concentrated sulfuric acid, the mass ratio of oil-removing waste material and concentrated sulfuric acid is 1: 1.2, after soaking for 3 hours, it is filtered, and washed 3 times with tap water, the filter residue is discarded, and the filtrate and washing liquid are combined; the above-mentioned combined feed liquid is placed in In the stirred reactor, stir at 200°C for 2 hours, then evenly add sodium sulfate and stir for 2 hours to form a double salt...

Embodiment 2

[0050] The preparation method of multi-rare earth phase permanent magnet material of the present invention, the method comprises the steps:

[0051] 1) Waste disposal:

[0052] a) Take NdFeB permanent magnet waste with a mass fraction of 10% Na 2 CO 3 solution to remove oil from waste, Na 2 CO 3 The mass ratio of waste to waste is 0.02:1. After the treated waste is filtered and washed 3 times, it is dried in an oven at 120°C for 1 hour to obtain deoiled waste; then the deoiled waste is placed in a concentration of 25% In the concentrated sulfuric acid, the mass ratio of oil-removing waste material and concentrated sulfuric acid is 1: 1.0, it is filtered after soaking for 2 hours, and washed 3 times with tap water, the filter residue is discarded, and the filtrate and washing liquid are combined; the above-mentioned combined feed liquid is placed in In the stirred reactor, stir at 150°C for 1 hour, then add sodium sulfate evenly and stir for 1-2 hours to form a double salt ...

Embodiment 3

[0063] In this example, the preparation of multi-rare earth phase permanent magnet material alloy ingot: according to the following mass percentage for batching: Nd18%, Y3.6%, La5.4%, Ce7.2%, Pr3.6%, Pd0.18%, Sm0 .36%, B3%, Co0.54%, Mn0.03%, Mo0.03%, and the rest is Fe. All the other preparation conditions and processes are the same as in Example 1. The mass percent content of N in the treated material is 0.35%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com