Patents

Literature

30results about How to "The ratio of ingredients is flexible" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Neodymium iron boron magnetic materials and preparation method of the same

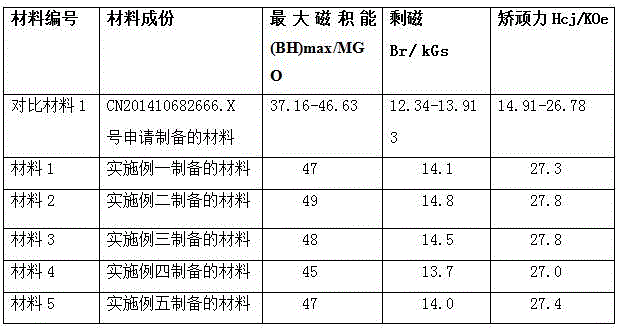

The invention discloses neodymium iron boron magnetic materials and a preparation method of the neodymium iron boron magnetic materials. The neodymium iron boron magnetic materials comprise, by weight, 27-34.5 % of neodymium (Nd), 4.5-5.75 % of praseodymium (Pr), 0.45-0.575 of gadolinium (Gd), 2-4% of boron (B), 0.08-0.16 % of niobium (Nb), 0.01-0.02 % of hafnium (Hf), 0.01-0.02 % of wolfram (W) and 0.045-0.0575 % of scandium (Sc), and the rest is ferrum (Fe). The neodymium iron boron magnetic materials have uniform textures and strong structures, and can not only improve tenacity performance of the materials but also improve magnetic performance to some extent. The preparation method of the neodymium iron boron magnetic materials fully utilizes praseodymium-neodymium waste materials to directly produce raw materials for alloy, is flexible in composition proportion, qualified in quality control, capable of reducing cost and simple in technology, and fully utilizes waste powder materials with high oxygen content.

Owner:江苏澳芯微电子有限公司

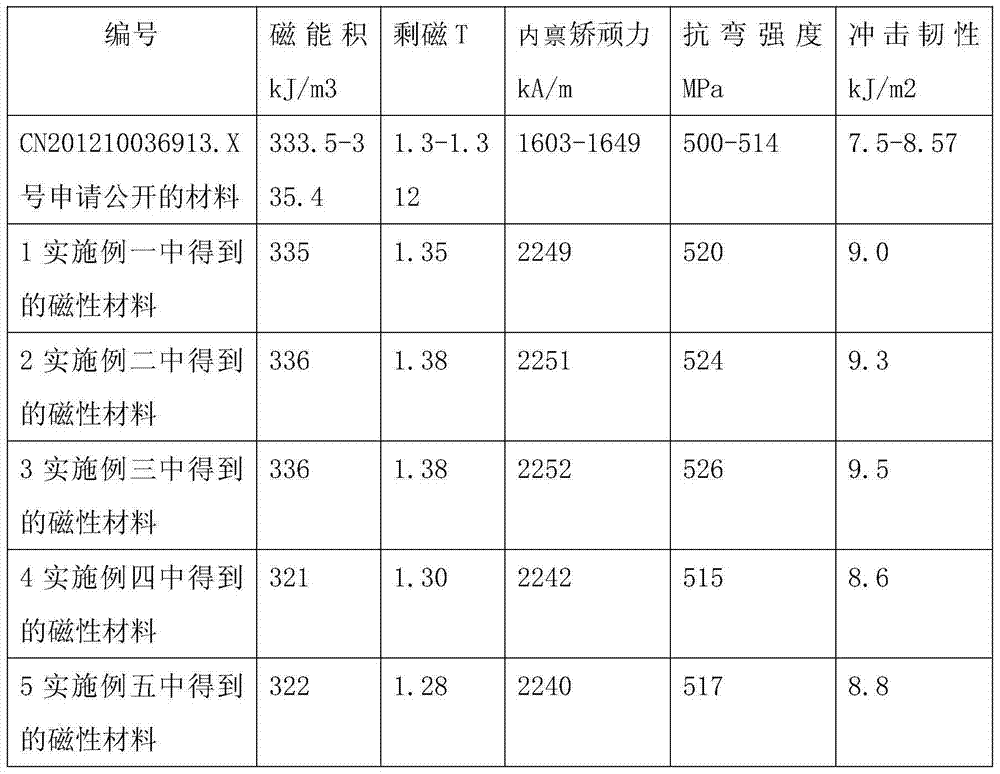

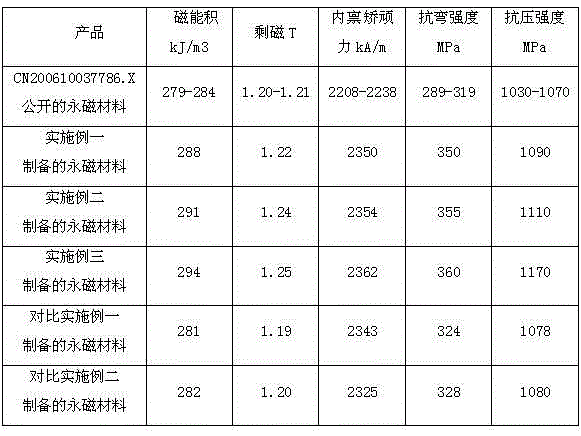

High bending force resistant permanent magnet materials and preparation method thereof

ActiveCN103106992AReduce stray magnetic fieldEasy to useMagnetic materialsRheniumManufactured material

The invention discloses high bending force resistant permanent magnet materials and a preparation method thereof. The magnet materials comprise, by weight, 22-30% neodymium, 4.4-6% praseodymium, 0.044-0.06% lanthanum, 2-5% boron, 0.044-0.06% molybdenum, 0.044-0.06% nickel, 0.044-0.06% rhenium, 0.044-0.06% scandium and the balance ferrum. The high bending force resistant permanent magnet materials are uniform in organization, strong in structure and capable of improving bending force resistant performance of the materials and magnetic performance. The preparation method of the magnet material takes full use of praseodymium-neodymium waste to directly produce raw materials used by alloy, composition proportion is flexible, quality is well controlled, cost is lowered, the process is simple and powder waste with high oxygen content is fully used.

Owner:XUZHOU NANFANG YONGCI MATERIAL

Magnetic material containing nitrogen-boron composite phase and preparation method

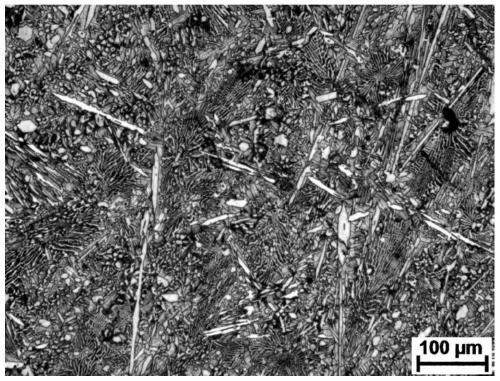

ActiveCN105489337AUniform tissueStrong and stable structureInorganic material magnetismMetallurgyNitrogen

The invention provides a magnetic material containing a nitrogen-boron composite phase. The magnetic material is high in residual magnetic flux density; the preparation method is simple in process, low in production cost and suitable for industrial production. The permanent magnet material comprises the following components in percentage by mass: 24-30% of Nd, 2.4-3.0% of Y, 3.6-4.5% of Eu, 1.2-1.5% of Ce, 1.2-1.5% of Tb, 2-4% of B, 0.2-0.6% of P, 0.12-0.3% of Ba, 0.45-0.60% of V and the balance of Fe, wherein the permanent magnet material also comprises 0.55-0.86% of N in percentage by mass.

Owner:XUZHOU NANFANG YONGCI MATERIAL

Rare earth permanent magnet material utilizing recycled waste materials and preparation method

The invention provides a rare earth permanent magnet material utilizing recycled waste materials. An alloy material is high in coercivity. The preparation method is simple in process, low in production cost and suitable for industrial production. The permanent magnet material comprises the following components in percentage by mass: 18-22% of Nd, 7.2-8.8% of Y, 3.6-4.4% of Eu, 3.6-4.4% of Dy, 2-6% of B, 0.1-0.5% of P, 0.15-0.20% of Ag, 0.45-0.60% of Ni, 0.01-0.04% of Si, 0.45-0.60% of Ti and the balance of Fe; the mass ratio of Nd to Y to Eu to Dy in the permanent magnet material is 10:4:2:2; and the permanent magnet material also comprises 0.045-0.060% of N in percentage by mass.

Owner:XUZHOU NANFANG YONGCI MATERIAL

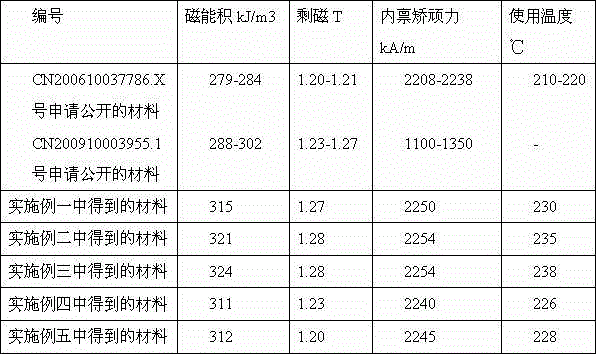

Heat-resistant neodymium iron boron material and preparation method thereof

The invention provides a heat-resistant neodymium iron boron material and a preparation method thereof. The material not only has good magnetic properties, but also has high heat resistance. The preparation method has a simple process and a low production cost, thus being suitable for industrialized production. The heat-resistant neodymium iron boron material comprises the following components by weight: 21-24% of Nd, 7-8% of Pr, 1-2% of B, 0.07-0.08% of Ir, 0.07-0.08% of Rh, 0.7-0.8% of Sc, and the rest Fe.

Owner:SHANXI SANYIQIANG MAGNETIC IND +1

Functional material and preparation method

ActiveCN105355355AUniform tissueStrong and stable structureInorganic material magnetismMedical deviceAerospace technology

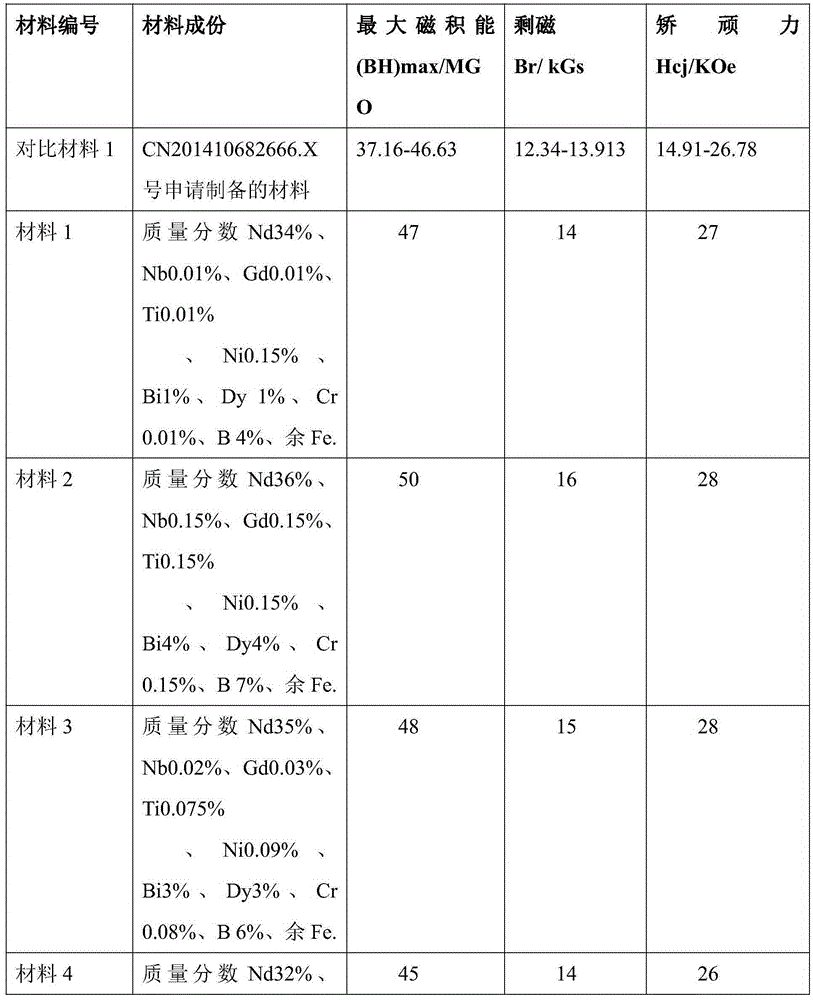

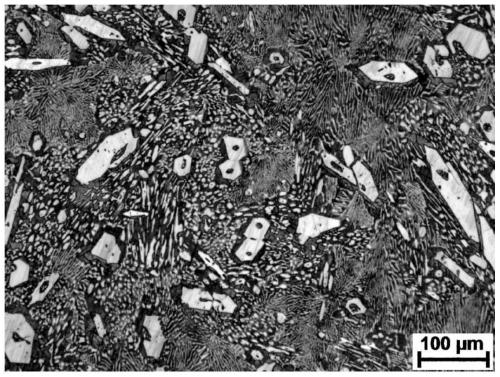

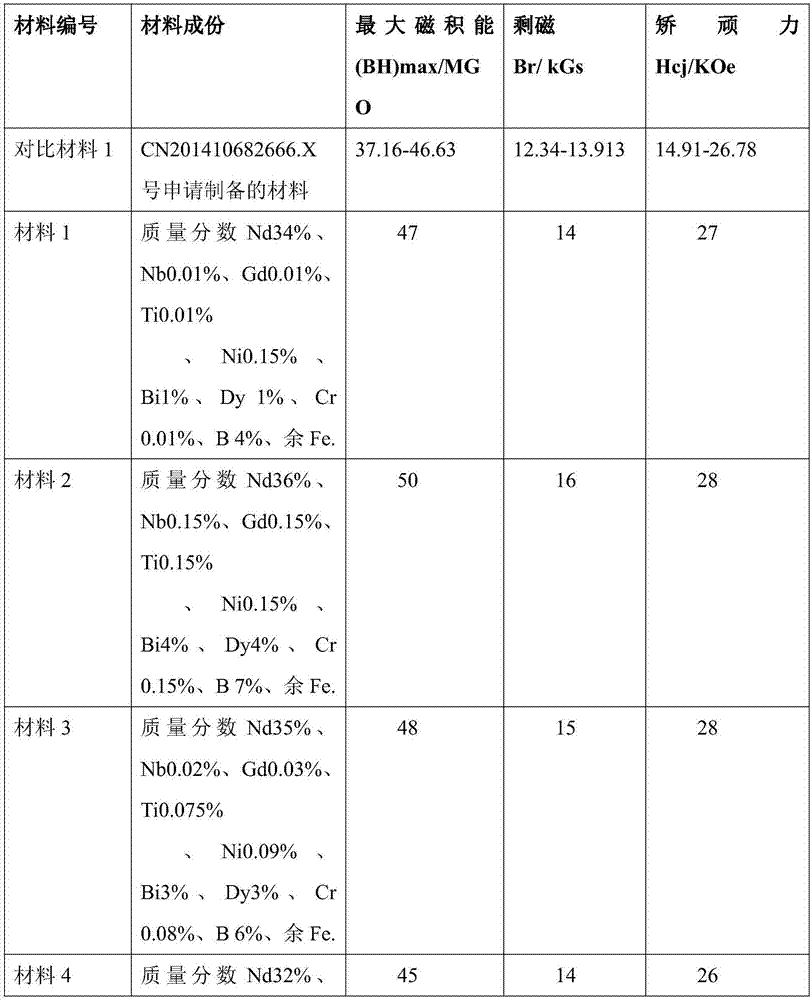

The invention discloses a functional material and a preparation method. The functional material is blended by components in percentage by mass as follows: 34%-36% of Nd, 0.01%-0.15% of Nb, 0.01%-0.15% of Gd, 0.01%-0.15% of Ti, 0.01%-0.15% of Ni, 1%-4% of Bi, 1%-4% of Dy, 0.01%-0.15% of Cr, 4%-7% of B and the balance of Fe. The functional material has uniform tissue and strong structure, the corrosion resistance of the material can be improved, and the magnetism is improved. The permanent magnet material has good stability and practicability and can be widely applied to various fields such as electronic devices, aerospace engineering, computer equipment, magnetic separators, communication equipment, medical equipment, electric bicycles, electronic toys and the like.

Owner:盐城市华达照明电器有限公司

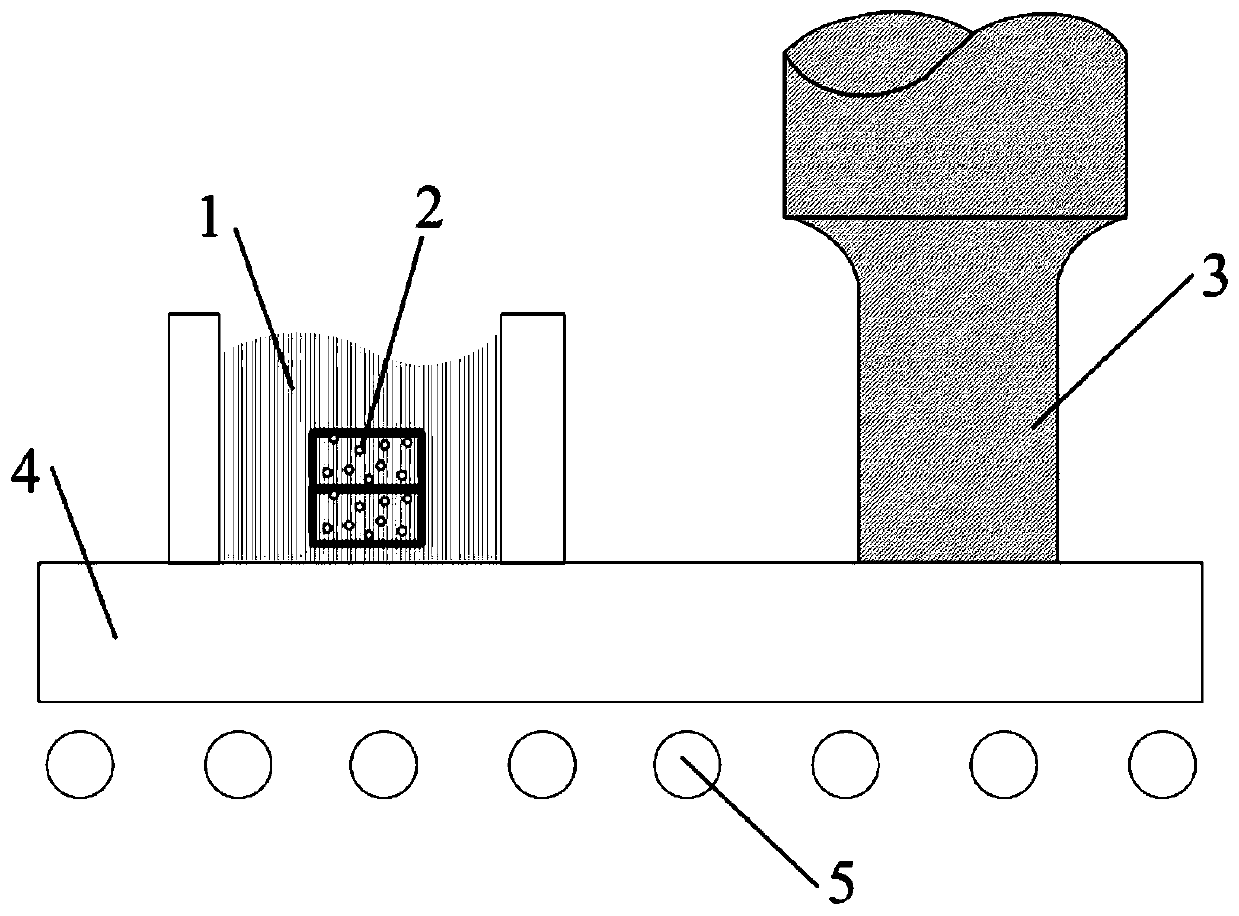

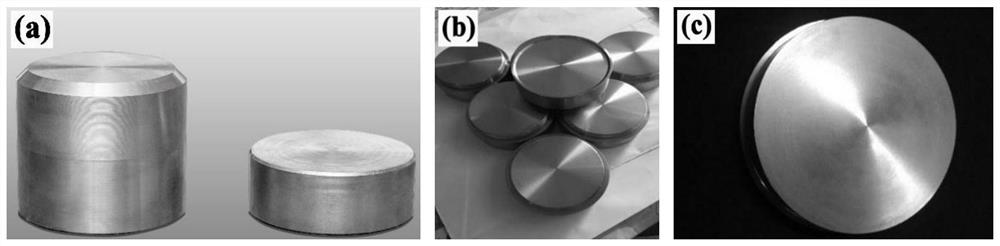

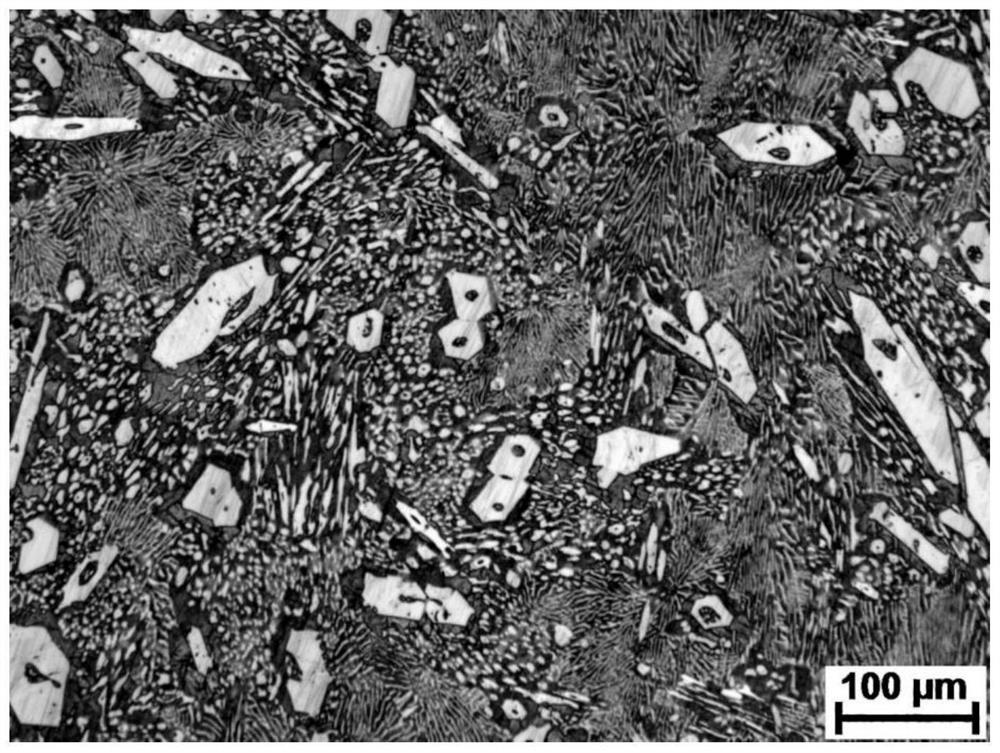

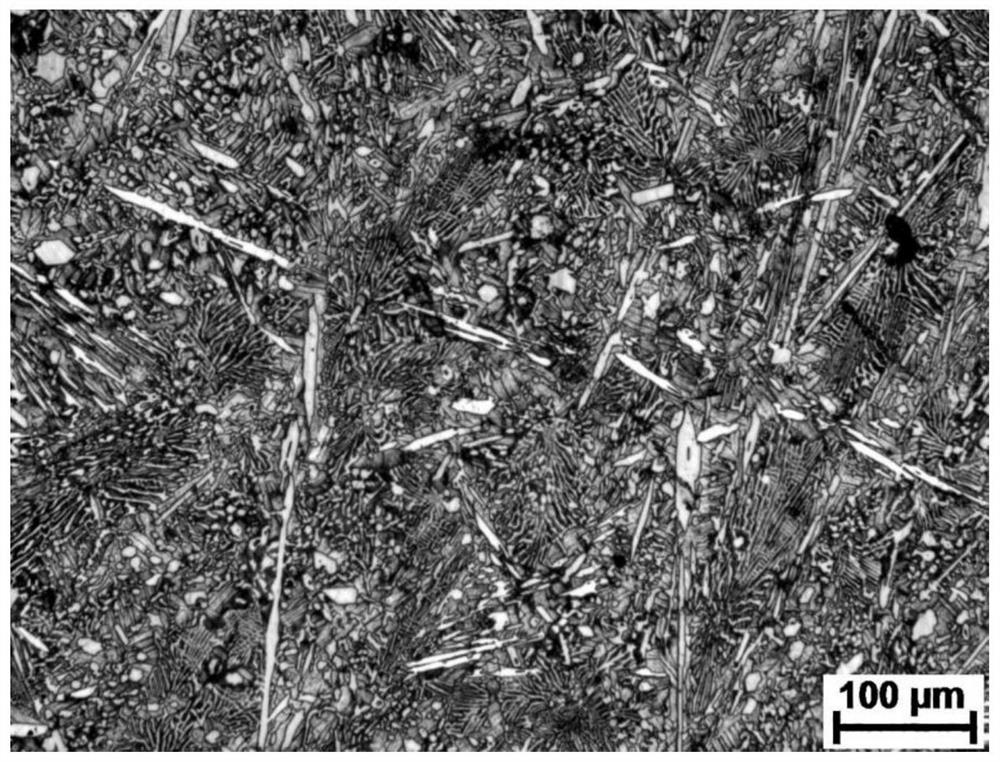

Low-cost preparation method of titanium silicon alloy target material

ActiveCN110257783AThe ratio of ingredients is flexibleUniform compositionVacuum evaporation coatingSputtering coatingSelf consumptionSilicon alloy

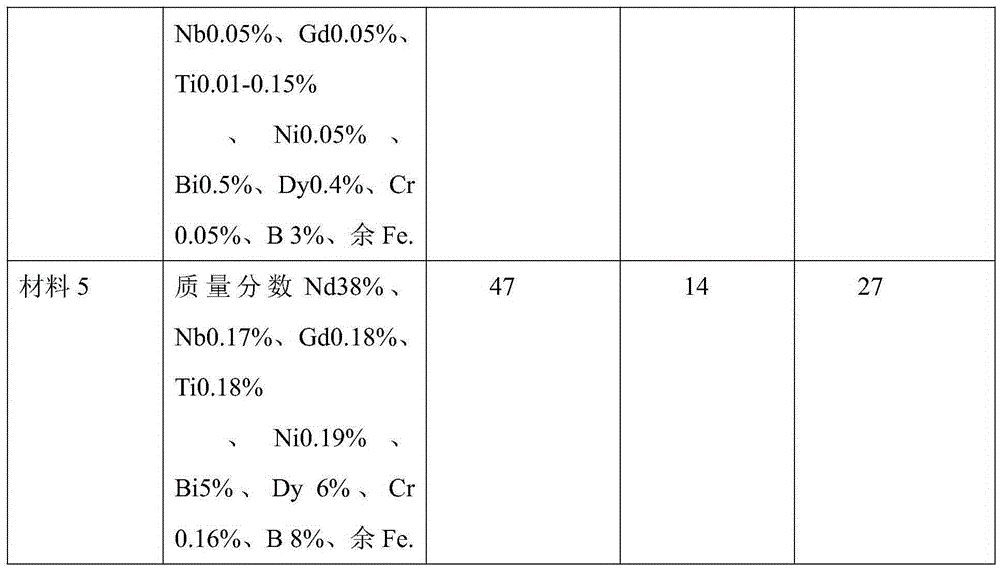

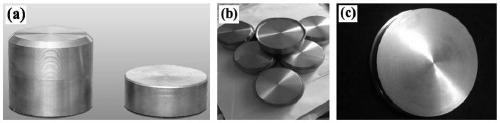

The invention provides a low-cost preparation method of a titanium silicon alloy target material. The low-cost preparation method of the titanium silicon alloy target material comprises the following steps of A, mixing: uniformly mixing sponge titanium and crystal silicon according to the proportion; B, pressing an electrode: pressing the mixed raw material into an electrode rod, and heating the electrode rod; C, carrying out self-consumption smelting for the first time: under a protective atmosphere, welding the heated electrode, then carrying out vacuum self-consumption smelting for the first time, and obtaining a primary ingot of titanium silicon alloy; D, welding: after flattening two ends of the primary ingot of the titanium silicon alloy, combining and welding the primary ingot of the titanium silicon alloy by utilizing a vacuum electron beam welding technology, and obtaining an electrode material; E, carrying out self-consumption smelting for the second time: carrying out vacuum self-consumption smelting on the electrode material for the second time, and obtaining a secondary ingot of the titanium silicon alloy; and F, processing the secondary ingot of the titanium silicon alloy, and obtaining the final titanium silicon target material. The titanium silicon target material prepared by the method provided by the invention has a compact structure, and is uniform and fine, high in raw material production rate, low in cost, and suitable for engineering mass production.

Owner:上海交通大学包头材料研究院 +1

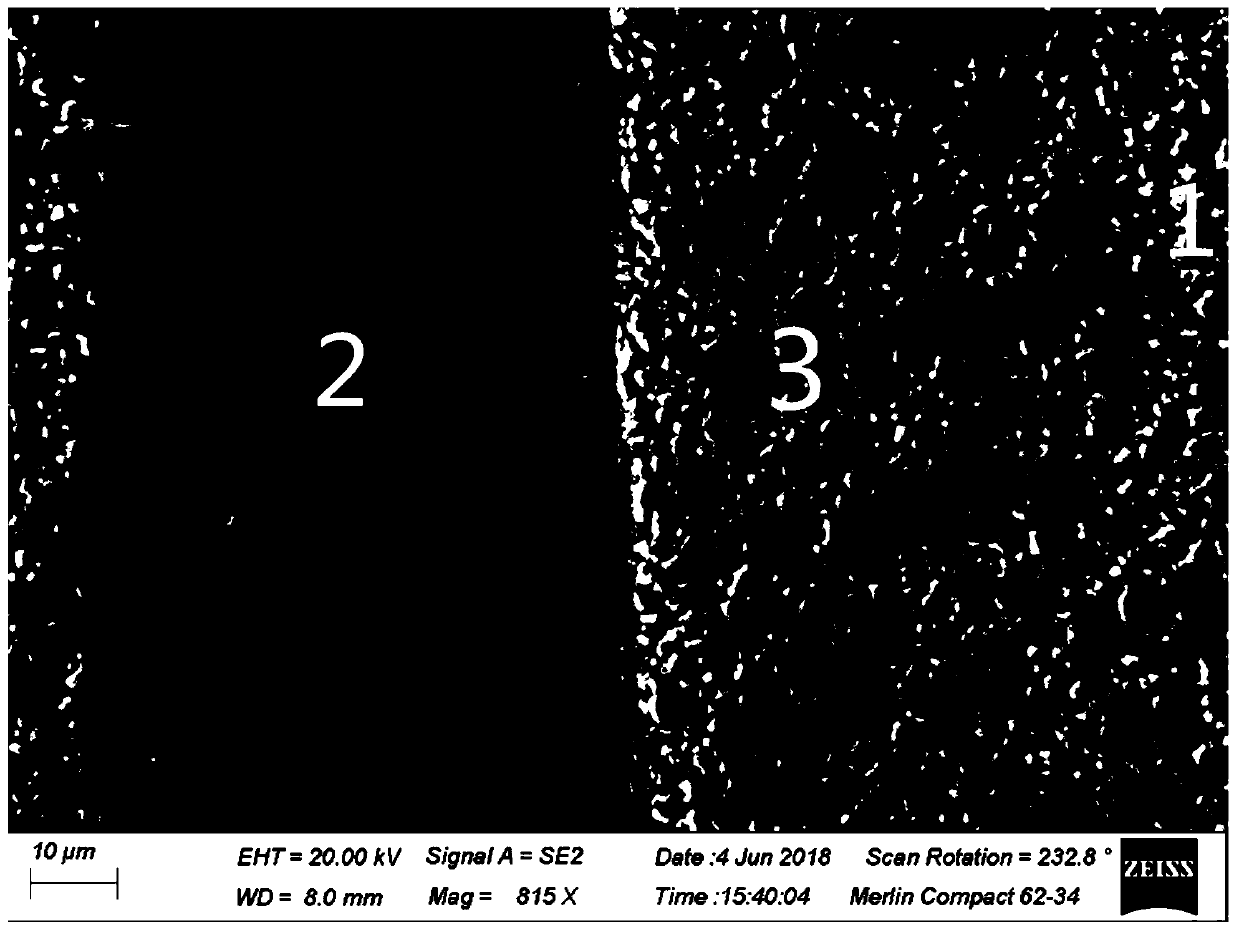

Method for ultrasonic-assisted porous ceramic brazing

ActiveCN109759662AFlexible choiceNot limited by ceramic compositionSoldering apparatusUltrasonic assistedPre treatment

The invention relates to a method for porous ceramic brazing, in particular to a method for ultrasonic-assisted porous ceramic brazing. The problems that as for existing ceramic / ceramic welding, a vacuum environment is needed, or the ceramic surface needs to be subjected to certain metallization treatment, the certain heat preservation time is needed, thus the welding efficiency is low, and jointperformance is low are solved. The preparation method comprises the steps: 1 to-be-welded part pretreatment, 2 ceramic wetting, and 3 ceramic welding, or the preparation method comprises the steps: 1porous ceramic pretreatment, and 2 ceramic welding. The method is used for ultrasonic-assisted porous ceramic brazing.

Owner:HARBIN INST OF TECH

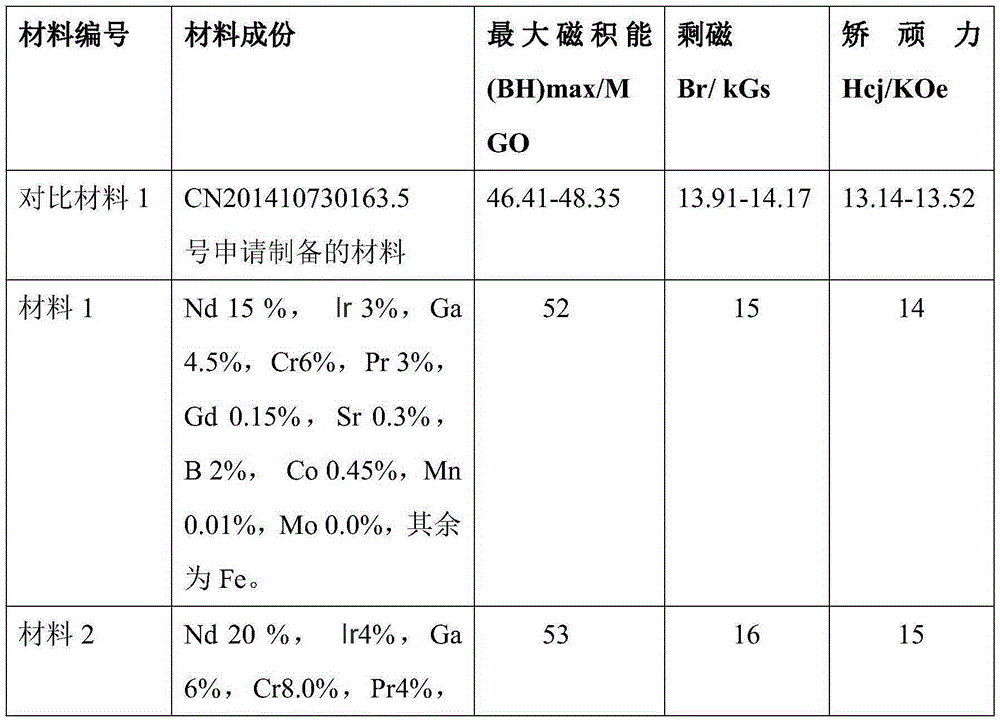

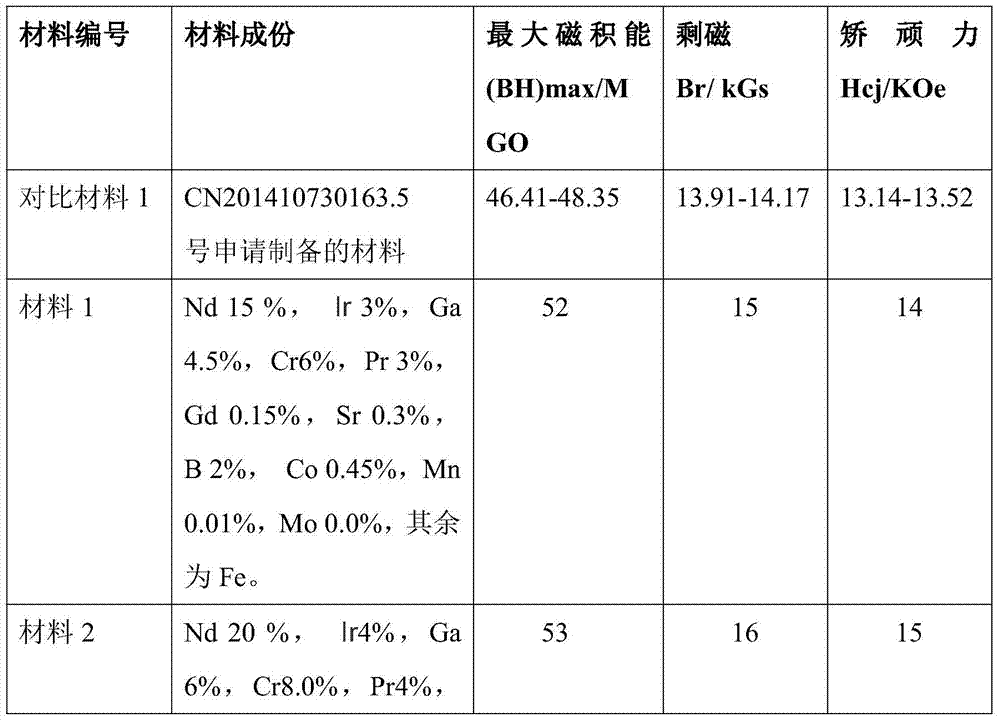

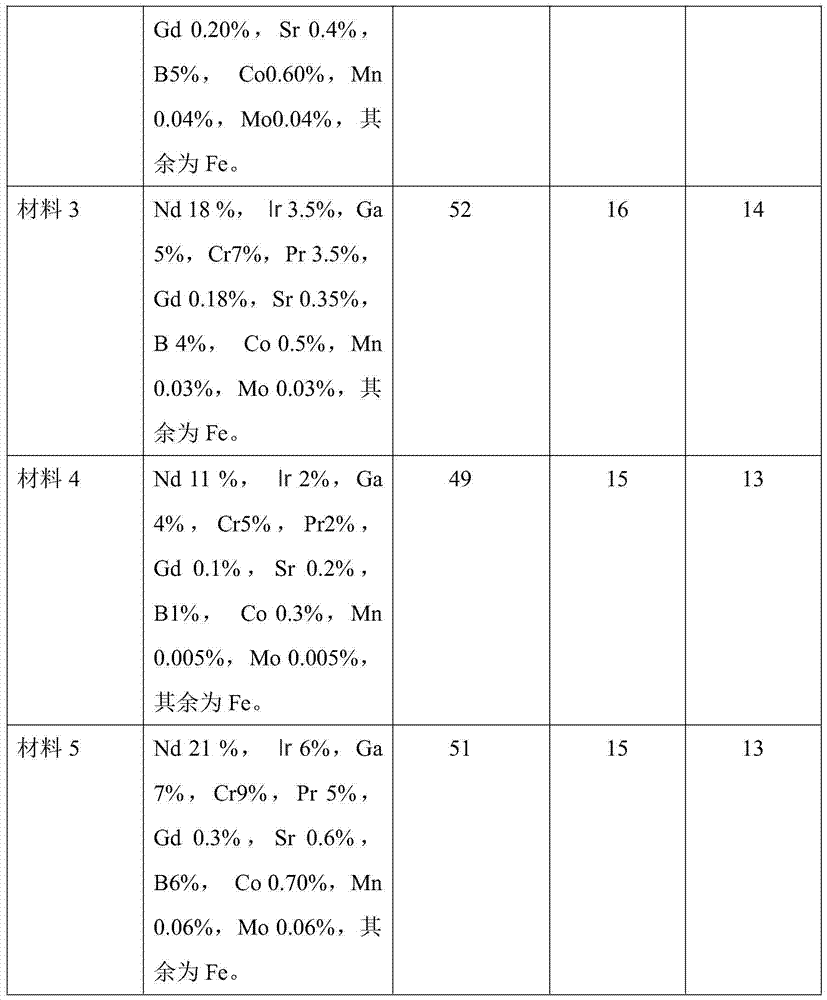

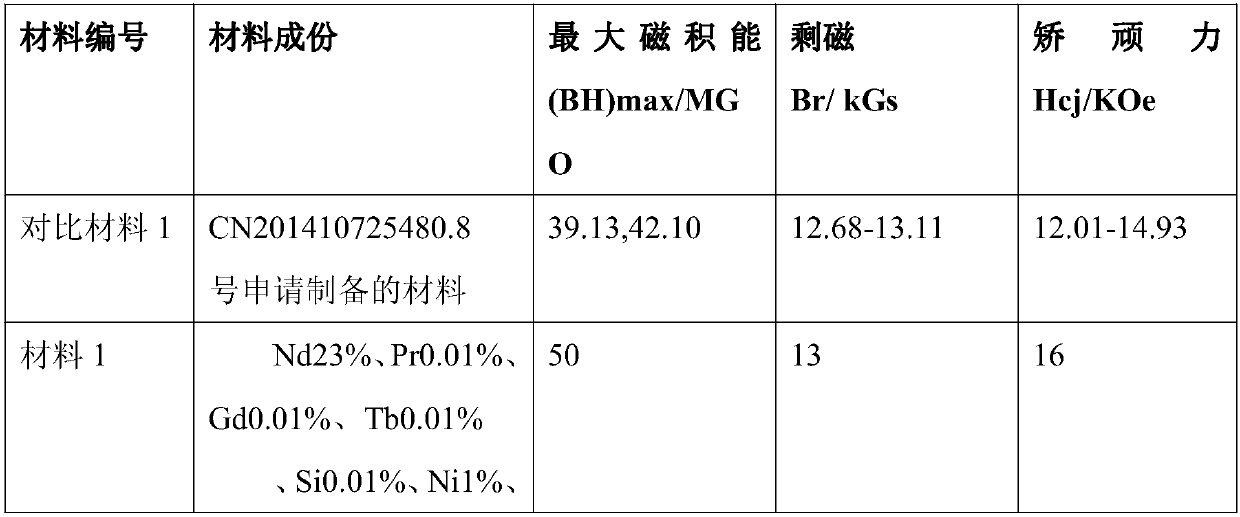

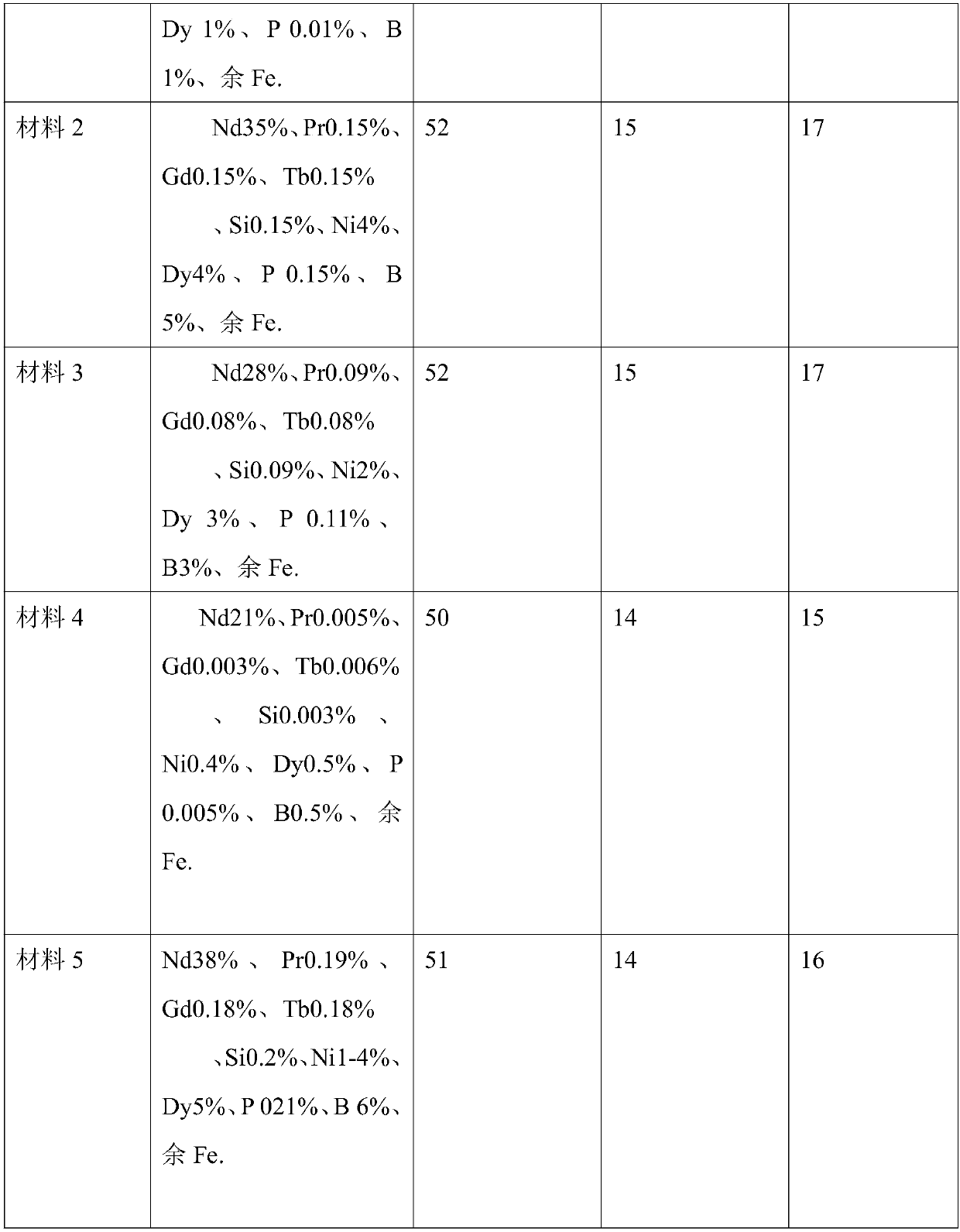

Multi-rare-earth-phase material and preparation method thereof

ActiveCN105405564AUniform tissueStrong and stable structureInorganic material magnetismRare earthMaterials science

The invention discloses a multi-rare-earth-phase material and a preparation method thereof. The material comprises the following components in percentage by mass: 15-20% of Nd, 3-4% of Ir, 4.5-6% of Ga, 6.0-8.0% of Cr, 3-4% of Pr, 0.15-0.20% of Gd, 0.3-0.4% of Sr, 2-5% of B, 0.45-0.60% of Co, 0.01-0.04% of Mn, 0.01-0.04% of Mo, and the balance of Fe. The material disclosed by the invention has the advantages of uniform texture and robust structure; in addition, the material is improved in corrosion resistance and magnetic property. The material is prepared by using the preparation method disclosed by the invention. The simple and effective anti-oxidation method can ensure a small difference in oxygen content between the surface and inside of a magnetic body and therefore makes the preparation of a high-performance rare earth material possible. The permanent magnet material disclosed by the invention has excellent stability and practicability, can be widely applied to various fields such as electronic devices, aerospace technology, computer equipment, magnetic separators, communication equipment, medical equipment, electric bicycles, electronic toys.

Owner:XUZHOU NANFANG YONGCI MATERIAL

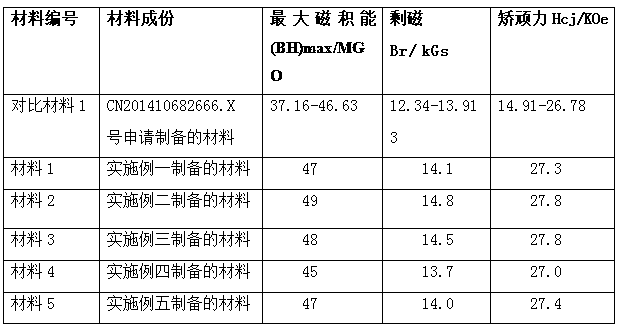

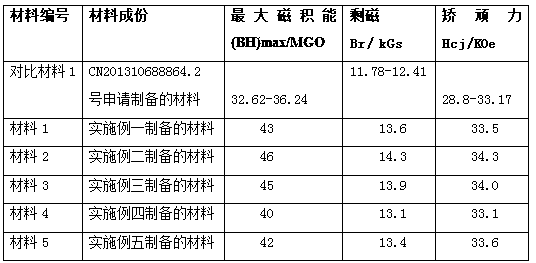

A kind of preparation method of NdFeB magnetic material

ActiveCN105702404BNovel methodThe ratio of ingredients is flexibleInorganic material magnetismAluminium powderSodium borohydride

The invention discloses a method for preparing a neodymium-iron-boron magnetic material, belonging to the technical field of materials. The preparation method disclosed by the invention comprises the following steps of: adding aluminium powder after mixing iron trioxide, neodymium oxide and Al3O4, burning by utilizing a magnesium rod to generate a reactant, then, initially separating the generated reactant to remove light substances, such as generated magnesium oxide and aluminium oxide, further oxidizing, adding sodium borohydride solution to reduce at high temperature, and roasting to obtain the neodymium-iron-boron magnetic material. Examples prove that the method disclosed by the invention is relatively simple, and simple and convenient to operate; the quality and the production efficiency of the neodymium-iron-boron magnetic material are increased; the production cost is reduced; furthermore, the prepared neodymium-iron-boron magnetic material is difficult to oxidize and good in corrosion resistance; and thus, the neodymium-iron-boron magnetic material can be suitable for large-scale popularization and application.

Owner:包头恒宇磁源科技有限公司

Multiphase permanent magnet material for waste recycling and preparation method thereof

Owner:XUZHOU NANFANG YONGCI MATERIAL

A method for ultrasonically assisted porous ceramic brazing

ActiveCN109759662BFlexible choiceNot limited by ceramic compositionSoldering apparatusUltrasonic assistedUltrasound assisted

The invention relates to a method for porous ceramic brazing, in particular to a method for ultrasonic-assisted porous ceramic brazing. The problems that as for existing ceramic / ceramic welding, a vacuum environment is needed, or the ceramic surface needs to be subjected to certain metallization treatment, the certain heat preservation time is needed, thus the welding efficiency is low, and jointperformance is low are solved. The preparation method comprises the steps: 1 to-be-welded part pretreatment, 2 ceramic wetting, and 3 ceramic welding, or the preparation method comprises the steps: 1porous ceramic pretreatment, and 2 ceramic welding. The method is used for ultrasonic-assisted porous ceramic brazing.

Owner:HARBIN INST OF TECH

Neodymium iron boron magnetic materials and preparation method of the same

ActiveCN103093916BImprove stray magnetic fieldImprove irreversible loss of magnetic fluxMagnetic materialsNiobiumHafnium

The invention discloses neodymium iron boron magnetic materials and a preparation method of the neodymium iron boron magnetic materials. The neodymium iron boron magnetic materials comprise, by weight, 27-34.5 % of neodymium (Nd), 4.5-5.75 % of praseodymium (Pr), 0.45-0.575 of gadolinium (Gd), 2-4% of boron (B), 0.08-0.16 % of niobium (Nb), 0.01-0.02 % of hafnium (Hf), 0.01-0.02 % of wolfram (W) and 0.045-0.0575 % of scandium (Sc), and the rest is ferrum (Fe). The neodymium iron boron magnetic materials have uniform textures and strong structures, and can not only improve tenacity performance of the materials but also improve magnetic performance to some extent. The preparation method of the neodymium iron boron magnetic materials fully utilizes praseodymium-neodymium waste materials to directly produce raw materials for alloy, is flexible in composition proportion, qualified in quality control, capable of reducing cost and simple in technology, and fully utilizes waste powder materials with high oxygen content.

Owner:江苏澳芯微电子有限公司

A heat-resistant NdFeB material and its preparation method

InactiveCN103146993BImprove stray magnetic fieldReduce stray magnetic fieldMetallurgyHeat resistance

The invention provides a heat-resistant neodymium-iron-boron material and a preparation method thereof. The material not only has good magnetism, but also has high heat resistance. The preparation method has simple process, low production cost and is suitable for industrialized production. The weight percentage of the heat-resistant NdFeB material is: Nd21-24%, Pr7-8%, B1-2%, Ir0.07-0.08%, Rh0.07-0.08%, Sc0.7-0.8 %, the rest is Fe.

Owner:SHANXI SANYIQIANG MAGNETIC IND +1

A low-cost preparation method of titanium-silicon alloy target

ActiveCN110257783BThe ratio of ingredients is flexibleUniform compositionVacuum evaporation coatingSputtering coatingSilicon alloyManufactured material

Owner:上海交通大学包头材料研究院 +1

Corrosion-resistant neodymium-iron-boron permanent magnet material and preparation method thereof

ActiveCN103077796BImprove stray magnetic fieldReduce stray magnetic fieldMagnetic materialsAlloyWaste material

The invention discloses a corrosion-resistant neodymium-iron-boron permanent magnet material and a preparation method thereof. The corrosion-resistant neodymium-iron-boron permanent magnet material comprises the following components in percentage by weight: 20-26 percent of Nd, 5-6.5 percent of Pr, 1-4 percent of B, 0.05-0.065 percent of Ir, 0.05-0.065 percent of Os, 0.5-0.65 percent of Sc, 0.5-0.65 percent of Cu and the balance of Fe. The corrosion-resistant neodymium-iron-boron permanent magnet material disclosed by the invention is provided with uniform tissue and a robust structure, so that the corrosion resistance of the material can be enhanced, and the magnetic performance is improved. According to the preparation method of the corrosion-resistant neodymium-iron-boron permanent magnet material, raw materials of an alloy are directly produced by fully utilizing praseodymium and neodymium waste, a component mixture ratio is flexible, and the quality is controlled appropriately; and moreover, the cost can be reduced, a process is simple, and powder waste with high oxygen content is fully utilized.

Owner:XUZHOU NANFANG YONGCI MATERIAL

A kind of functional material and preparation method

ActiveCN105355355BImprove temperature stabilityWide operating temperature rangeInorganic material magnetismMedical equipmentMagnetic separator

The invention discloses a functional material and a preparation method. The functional material is blended by components in percentage by mass as follows: 34%-36% of Nd, 0.01%-0.15% of Nb, 0.01%-0.15% of Gd, 0.01%-0.15% of Ti, 0.01%-0.15% of Ni, 1%-4% of Bi, 1%-4% of Dy, 0.01%-0.15% of Cr, 4%-7% of B and the balance of Fe. The functional material has uniform tissue and strong structure, the corrosion resistance of the material can be improved, and the magnetism is improved. The permanent magnet material has good stability and practicability and can be widely applied to various fields such as electronic devices, aerospace engineering, computer equipment, magnetic separators, communication equipment, medical equipment, electric bicycles, electronic toys and the like.

Owner:盐城市华达照明电器有限公司

A kind of permanent magnet material with high compressive strength and preparation method thereof

The invention discloses a permanent magnet material with high pressure resisting intensity and a preparation method of the permanent magnet material with high pressure resisting intensity. The permanent magnet material with high pressure resisting intensity comprises, by weight, 14.4-24% of neodymium, 3.6-6% of praseodymium, 1-5% of boron, 0.036-0.06% of wolfram, 1-3% of niobium, 0.012-0.02% of rhenium, 0.036-0.06% of scandium, and the rest is ferrum, wherein the weight ratio among neodymium, praseodymium and wolfram is 4:1:0.01, and the weight ratio between wolfram and rhenium is 3:1. Due to the fact that permanent magnet material with high pressure resisting intensity utilizes neodymium and praseodymium waste to directly generate raw material of an alloy, composition proportion is flexible, quality is well controlled, and cost can be reduced, process is simple, powder waste high in oxygen content is fully utilized, environment is protected and effectively improved, and high social value is possessed.

Owner:SHANXI SANYIQIANG MAGNETIC IND +1

High bending force resistant permanent magnet materials and preparation method thereof

ActiveCN103106992BReduce stray magnetic fieldEasy to useMagnetic materialsRheniumManufactured material

The invention discloses high bending force resistant permanent magnet materials and a preparation method thereof. The magnet materials comprise, by weight, 22-30% neodymium, 4.4-6% praseodymium, 0.044-0.06% lanthanum, 2-5% boron, 0.044-0.06% molybdenum, 0.044-0.06% nickel, 0.044-0.06% rhenium, 0.044-0.06% scandium and the balance ferrum. The high bending force resistant permanent magnet materials are uniform in organization, strong in structure and capable of improving bending force resistant performance of the materials and magnetic performance. The preparation method of the magnet material takes full use of praseodymium-neodymium waste to directly produce raw materials used by alloy, composition proportion is flexible, quality is well controlled, cost is lowered, the process is simple and powder waste with high oxygen content is fully used.

Owner:XUZHOU NANFANG YONGCI MATERIAL

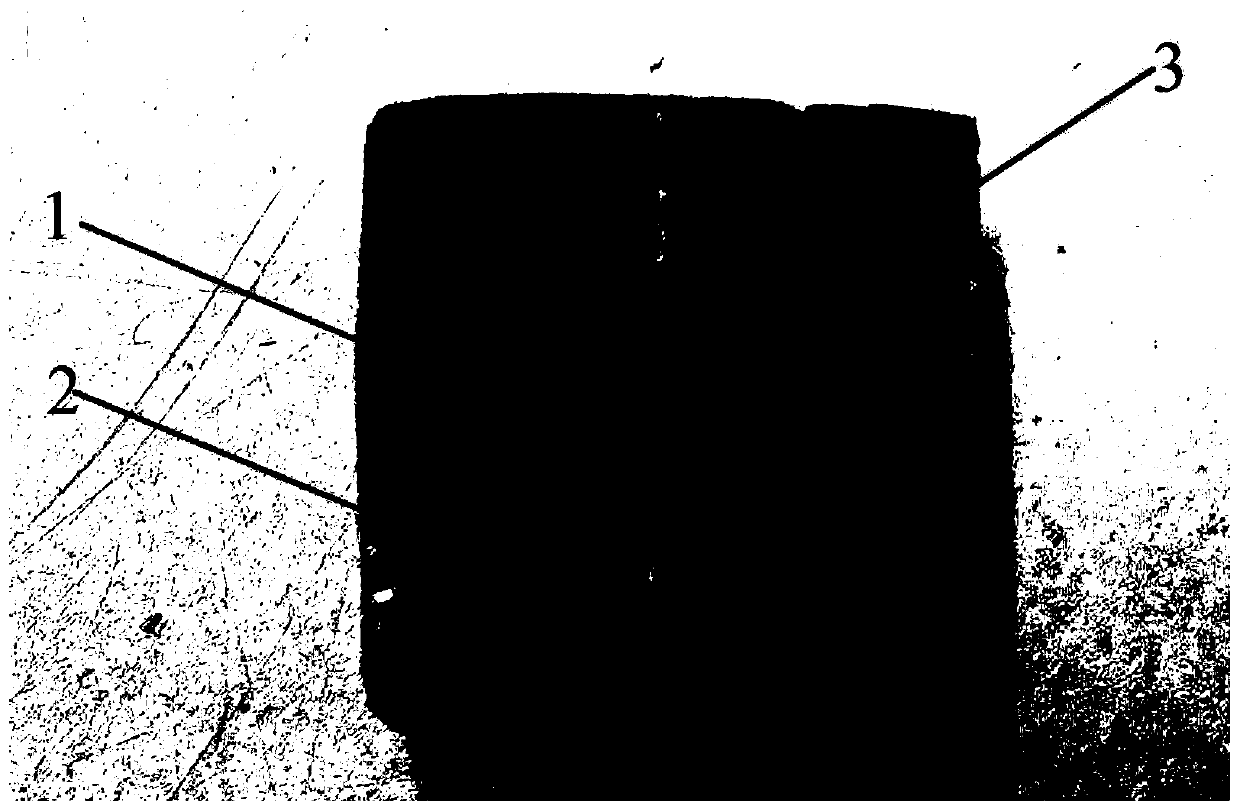

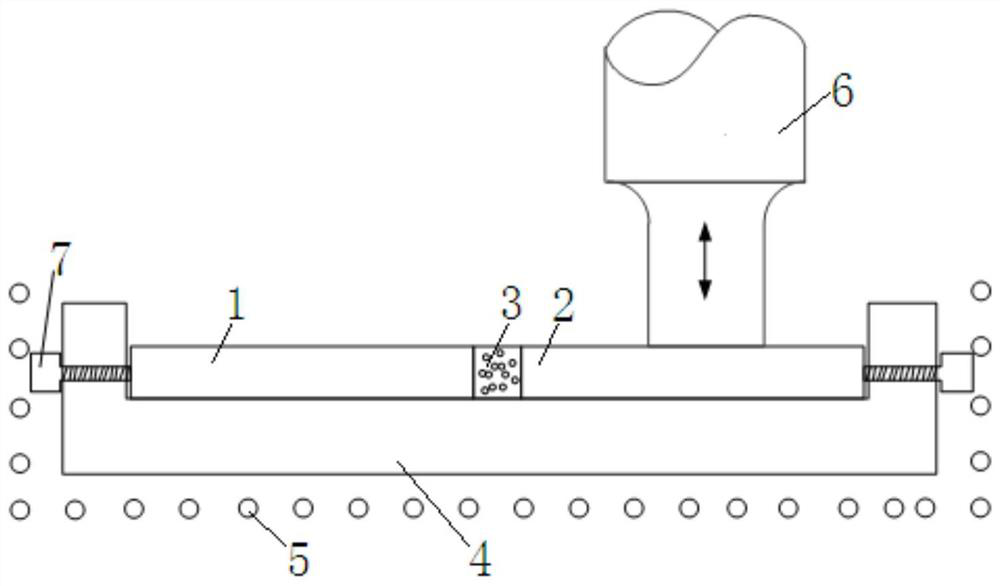

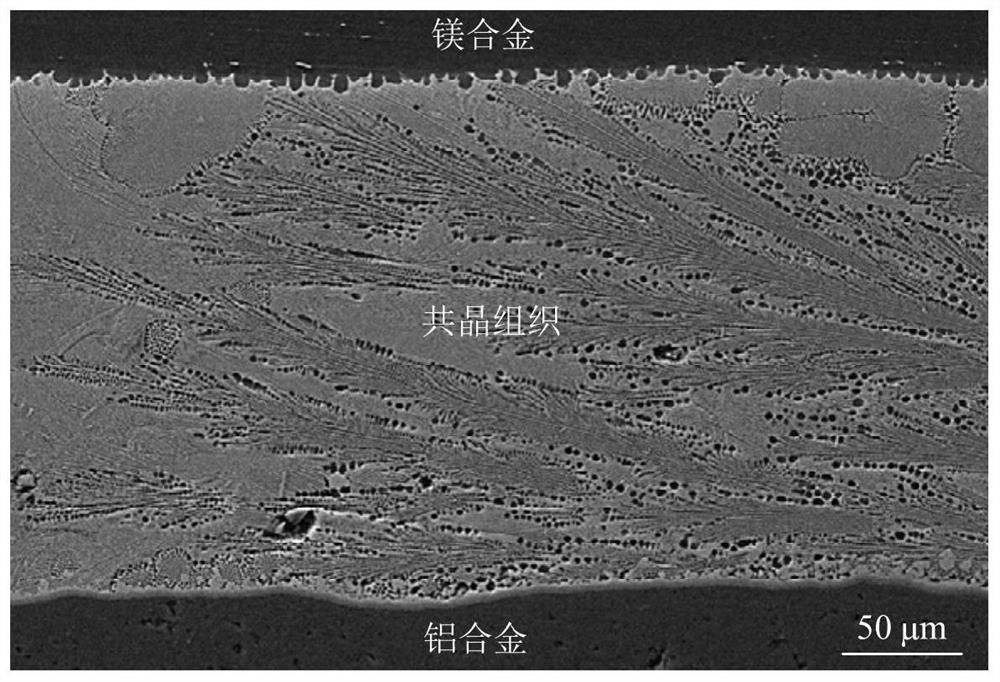

Ultrasonic-assisted semi-solid welding method of aluminum alloy and magnesium alloy

ActiveCN109773294BImprove welding efficiencyFlexible choiceSoldering apparatusUltrasonic cavitationWeld seam

The invention provides an ultrasonic-assisted semi-solid welding method used for aluminum alloy and magnesium alloy, and relates to a welding method used for aluminum alloy and magnesium alloy. By adoption of the ultrasonic-assisted semi-solid welding method used for aluminum alloy and magnesium alloy, the problems that according to a traditional welding method for aluminum alloy and magnesium alloy, hard and fragile intermetallic compounds are generated due to the high welding temperature; and a welding method based on an intermediate layer needs a vacuum or gas-shielded environment and is low in welding efficiency are solved. The ultrasonic-assisted semi-solid welding method used for aluminum alloy and magnesium alloy comprises the first step of selection of solder components, the secondstep of solder preparation, the third step of pre-treatment for obtaining a to-be-welded assembly, and the fourth step of application of ultrasonic vibration when the temperature reaches a welding temperature so as to conduct welding under the ultrasonic cavitation effect. The ultrasonic-assisted semi-solid welding method used for aluminum alloy and magnesium alloy has the beneficial effects thatfirstly, the welding efficiency of aluminum and magnesium is improved, and intermetallic compounds in weld joints are eliminated; secondly, the solder can be selected flexibly; thirdly, the solder components can be proportioned flexibly; fourthly, the welding temperature is low; fifthly, the ultrasonic application position is flexible; and sixthly, the cost is low, and the adaptability is high. The ultrasonic-assisted semi-solid welding method is mainly used for welding aluminum alloy and magnesium alloy.

Owner:HARBIN INST OF TECH

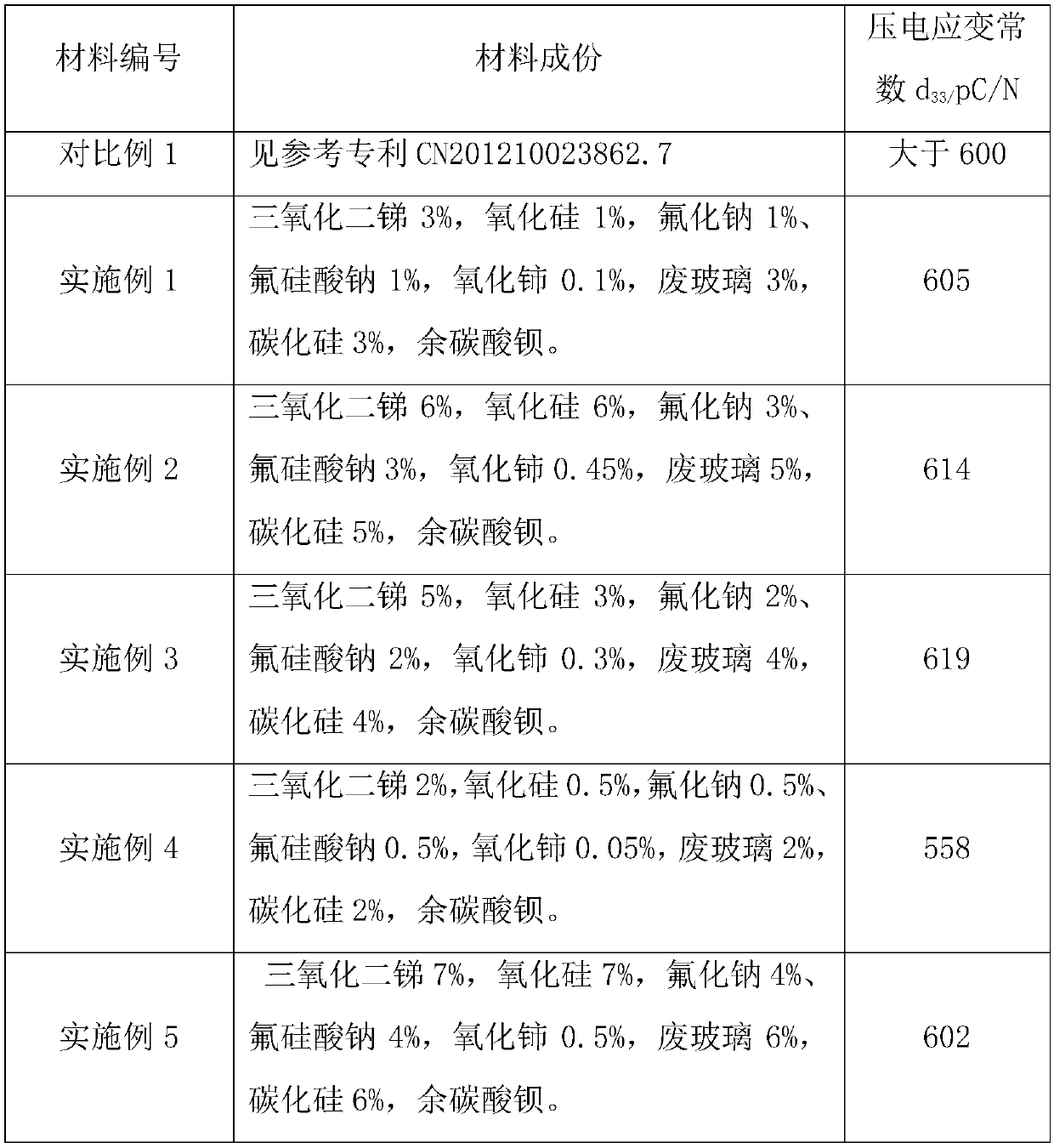

A kind of piezoelectric functional porous electrode composite material and its preparation method

ActiveCN106206928BAvoid violent oxidationLower sintering temperaturePiezoelectric/electrostrictive device manufacture/assemblyPolystyreneCerium

The invention relates to a piezoelectric functional porous electrode composite material and a preparation method thereof. The ingredients are prepared according to the following mass percentages: 3-6% of antimony trioxide, 1-6% of silicon oxide, 1-3% of sodium fluoride, and fluorosilicic acid Sodium 1‑3%, cerium oxide 0.1‑0.45%, waste glass 3‑5%, silicon carbide 3‑5%, and the balance is barium carbonate. The material preparation process includes ball milling, pressing on a tablet press, sintering in a resistance furnace, ball milling again, mixing and pressing with polystyrene copolymer SEBS, and the like. Due to the reducibility of the silicon carbide, the invention effectively prevents the violent oxidation of the material, can make the difference of the oxygen content between the surface of the material and the inside of the material smaller, and makes it possible to obtain a high-performance material. With barium carbonate as the matrix, various conductive ions such as antimony and cerium are distributed on it, which not only has a uniform piezoelectric structure, but also has a strong structure; the combination of antimony and cerium can not only improve the dielectric properties of the material, but also ensure The piezoelectricity of the material. The invention can reduce cost, has simple process and is environmentally friendly, and the prepared material has good stability and practicability.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

A kind of multi-rare earth phase material and preparation method thereof

ActiveCN105405564BUniform tissueStrong and stable structureInorganic material magnetismRare earthOxygen content

Owner:XUZHOU NANFANG YONGCI MATERIAL

Magnetic material and preparation method thereof

ActiveCN105405565BUniform tissueStrong and stable structureInorganic material magnetismEngineeringElectron

The invention discloses a magnetic material and a preparation method thereof. The magnetic material has a uniform tissue and a strong structure; the anti-corrosion capability of the material can be improved; and the magnetic property is also improved. The magnetic material has good stability and practicability, and can be widely applied to various fields of an electronic device, an aerospace technology, computer equipment, a magnetic separator, communication equipment, medical equipment, an electric bicycle, an electronic toy and the like. According to the preparation method of a permanent magnet material disclosed by the invention, wastes are fully utilized as an alloy raw material directly; the composition proportion is flexible; the quality control is in place; the cost can be reduced; the process is simple; a power waste with high oxygen content is fully utilized; the method is environment-friendly and has high social value; and the environment is effectively improved.

Owner:苏州圆格电子有限公司

Nitrogen-boron composite phase magnetic material and preparation method thereof

ActiveCN105489337BChange direct exchangeImprove coercive forceInorganic material magnetismNitrogenVolumetric Mass Density

The invention provides a magnetic material containing a nitrogen-boron composite phase. The magnetic material is high in residual magnetic flux density; the preparation method is simple in process, low in production cost and suitable for industrial production. The permanent magnet material comprises the following components in percentage by mass: 24-30% of Nd, 2.4-3.0% of Y, 3.6-4.5% of Eu, 1.2-1.5% of Ce, 1.2-1.5% of Tb, 2-4% of B, 0.2-0.6% of P, 0.12-0.3% of Ba, 0.45-0.60% of V and the balance of Fe, wherein the permanent magnet material also comprises 0.55-0.86% of N in percentage by mass.

Owner:XUZHOU NANFANG YONGCI MATERIAL

A kind of high toughness magnetic material and preparation method thereof

ActiveCN103093915BImprove stray magnetic fieldImprove irreversible loss of magnetic fluxMagnetic materialsHafniumBoron

The invention discloses high tenacity magnetic materials and a preparation method of the high tenacity magnetic materials. The component percentages of the high tenacity magnetic materials comprise, by weight, 28-38% of neodymium (Nd), 2.8-3.8% of praseodymium (Pr), 1-4% of boron (B), 0.09-0.198% of tantalum (Ta), 0.08-0.176 % of hafnium (Hf), 0.02-0.044 % of wolfram (W) and 0.028-0.038% of scandium (Sc), and the rest is ferrum (Fe). The high tenacity magnetic materials have uniform textures and strong structures, and can not only improve tenacity performance of the materials but also improve magnetic performance. The preparation method fully utilizes praseodymium-neodymium waste materials to directly produce raw materials for alloy, is flexible in composition proportion, qualified in quality control, capable of reducing cost and simple in technology, and fully utilizes waste powder materials with high oxygen content.

Owner:江苏澳芯微电子有限公司

Composite waste recycling rare earth magnetic material and preparation method

The invention provides a composite waste-material-recycled rare earth magnetic material and a preparation method therefor. The alloy material has relatively high coercivity. The preparation method is simple in process, low in production cost, and suitable for realizing industrial production. The material comprises the following components based on mass percentage: 30-35% of Nd, 0.6-0.7% of Y, 1.2-1.4% of Ce, 0.6-0.7% of La, 1.2-1.4% of Pr, 0.3-0.35% of Gd, 0.6-0.7% of Sm, 0.6-0.7% of Co, 2-6% of B, 1.25-1.86% of N, 0.3-0.35% of Hf, 0.3-0.35% of Be and the balance of Fe; and the 1.25-1.86% of N based on mass percentage is included in the material.

Owner:XUZHOU NANFANG YONGCI MATERIAL

Nitrogen-containing permanent magnet material and preparation method

ActiveCN106876074BHigh residual magnetic inductionHigh saturation magnetizationInorganic material magnetismNitrogenMagnetic flux

The invention provides a nitrogen-containing permanent magnet material and a preparation method therefor. The nitrogen-containing permanent magnet material has relatively high residual magnetic flux density. The preparation method is simple in process, low in production cost, and suitable for realizing industrial production. The permanent magnet material comprises the following components based on mass percentage: 22-25% of Nd, 4.4-5.0% of Ce, 6.6-7.5% of La, 0.22-0.25% of Tm, 3-6% of B, 1.5-1.8% of N, 0.15-0.18% of Ti, 0.22-0.25% of Sn, 0.22-0.25% of Ta and the balance of Fe; and the 1.5-1.8% of N based on mass percentage is included in the material.

Owner:XUZHOU NANFANG YONGCI MATERIAL

Nitrogen-containing permanent magnet material and preparation method therefor

ActiveCN106876074AUniform tissueImprove corrosion resistanceInorganic material magnetismNitrogenUltimate tensile strength

The invention provides a nitrogen-containing permanent magnet material and a preparation method therefor. The nitrogen-containing permanent magnet material has relatively high residual magnetic flux density. The preparation method is simple in process, low in production cost, and suitable for realizing industrial production. The permanent magnet material comprises the following components based on mass percentage: 22-25% of Nd, 4.4-5.0% of Ce, 6.6-7.5% of La, 0.22-0.25% of Tm, 3-6% of B, 1.5-1.8% of N, 0.15-0.18% of Ti, 0.22-0.25% of Sn, 0.22-0.25% of Ta and the balance of Fe; and the 1.5-1.8% of N based on mass percentage is included in the material.

Owner:XUZHOU NANFANG YONGCI MATERIAL

Rare earth permanent magnet material recycled from waste and preparation method thereof

The invention provides a rare earth permanent magnet material utilizing recycled waste materials. An alloy material is high in coercivity. The preparation method is simple in process, low in production cost and suitable for industrial production. The permanent magnet material comprises the following components in percentage by mass: 18-22% of Nd, 7.2-8.8% of Y, 3.6-4.4% of Eu, 3.6-4.4% of Dy, 2-6% of B, 0.1-0.5% of P, 0.15-0.20% of Ag, 0.45-0.60% of Ni, 0.01-0.04% of Si, 0.45-0.60% of Ti and the balance of Fe; the mass ratio of Nd to Y to Eu to Dy in the permanent magnet material is 10:4:2:2; and the permanent magnet material also comprises 0.045-0.060% of N in percentage by mass.

Owner:XUZHOU NANFANG YONGCI MATERIAL

Multi-rare earth phase permanent magnet material and preparation method

ActiveCN105489332BImprove coercive forceWell formedInorganic material magnetismSolid state diffusion coatingMetallurgyRare earth

The invention provides a permanent magnet material containing multiple rare earth phases and a preparation method. The permanent magnet material is high in magnetic energy product; the preparation method is simple in process, low in production cost and suitable for industrial production. The permanent magnet material containing the multiple rare earth phases comprises the following components in percentage by mass: 15-20% of Nd, 3-4% of Y, 4.5-6% of La, 6.0-8.0% of Ce, 3-4% of Pr, 0.15-0.20% of Pd, 0.3-0.4% of Sm, 2-5% of B, 0.45-0.60% of Co, 0.01-0.04% of Mn, 0.01-0.04% of Mo and the balance of Fe; the mass ratio of Pd to Co in the permanent magnet material is 1:3; the mass ratio of Nd to Y to La to Ce to Pr to Pd to Sm is 10:2:3:4:2:0.1:0.2; and the permanent magnet material also comprises 0.15-0.55% of N in percentage by mass.

Owner:XUZHOU NANFANG YONGCI MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com