Neodymium iron boron magnetic materials and preparation method of the same

A magnetic material and NdFeB technology, applied in the field of NdFeB magnetic materials and preparation, can solve the problems of insufficient magnetic properties of materials and insufficient damage resistance of materials, and achieve improved environment, good stability and practicability, and high social effect of value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

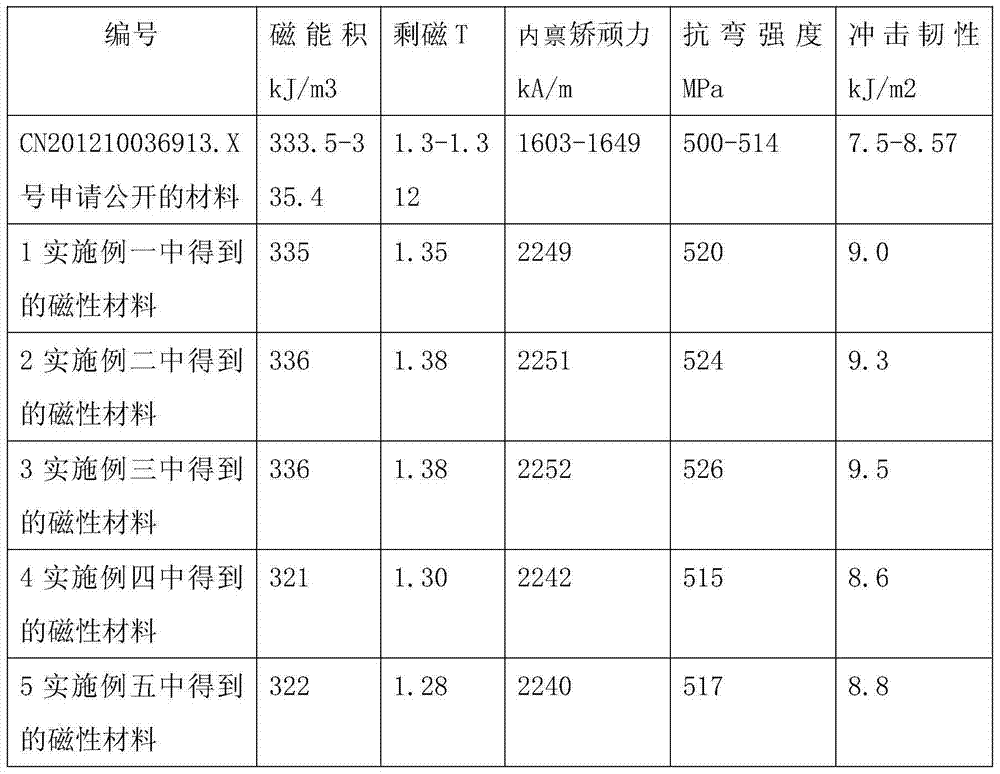

Examples

Embodiment 1

[0027] Prepare high-toughness magnetic materials according to the following steps:

[0028] 1) PrNd waste treatment: place praseodymium neodymium waste in hydrochloric acid with a mass concentration of 25% and mix them. The mass ratio of praseodymium neodymium waste to hydrochloric acid is 1:2.0, then add oxalic acid into the hydrochloric acid mixture and stir evenly, then mix the oxalic acid with hydrochloric acid The weight ratio of the solution was 2.5:1. The precipitate collected after 1 hour was dried at a temperature of 120° C. for 1 hour, and then kept at a temperature of 1050° C. for 1.5 hours to obtain a precipitated rare earth oxide.

[0029]2) Grinding ingredients: measure the content of Nd, Pr, Gd and Sc on the precipitated rare earth oxide, and add praseodymium oxide powder, neodymium oxide powder, gadolinium oxide powder and scandium oxide powder to the precipitated rare earth oxide to adjust the composition. The weight ratio of the four components of Nd, Pr, Gd ...

Embodiment 2

[0035] Prepare high-toughness magnetic materials according to the following steps:

[0036] 1) Treatment of praseodymium and neodymium waste: place praseodymium and neodymium waste in hydrochloric acid with a mass concentration of 30% and mix them, the mass ratio of praseodymium and neodymium waste to hydrochloric acid is 1:2.3, then add oxalic acid into the hydrochloric acid mixture and stir evenly, and mix the oxalic acid and hydrochloric acid The weight ratio of the solution is 2.5:1. The precipitate collected after 2 hours is dried at a temperature of 120°C for 1 hour, and then kept at a temperature of 1100°C for 1.5 hours to obtain a precipitated rare earth oxide;

[0037] 2) Grinding ingredients: measure the content of Nd, Pr, Gd and Sc on the precipitated rare earth oxide, and add praseodymium oxide powder, neodymium oxide powder, gadolinium oxide powder and scandium oxide powder to the precipitated rare earth oxide to adjust the composition. The weight ratio of the fou...

Embodiment 3

[0043] When preparing the magnetic alloy ingot in step 4), the ingredients are distributed according to the following weight percentages: Nd 30%, Pr 5%, Gd 0.5%, B 3%, Nb 0.12%, Hf 0.015%, W 0.015%, Sc 0.05%, the rest For Fe.

[0044] All the other preparation processes are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com