Low-cost preparation method of titanium silicon alloy target material

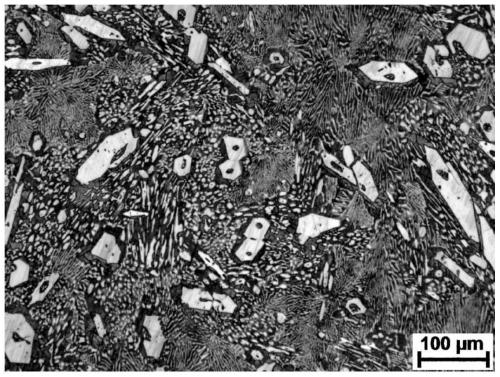

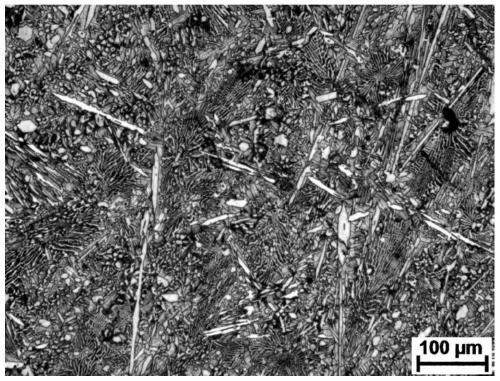

A titanium-silicon alloy, low-cost technology, applied in metal material coating process, ion implantation plating, coating, etc., can solve problems such as uneven structure, composition segregation, high cost, etc., to improve composition uniformity and metallurgical The effect of uniform quality, structure and composition, low yield and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

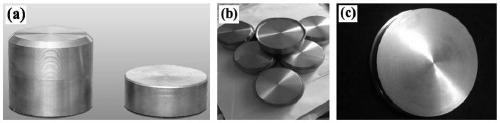

Examples

Embodiment 1

[0039] The titanium-silicon alloy target of the present invention is made of raw materials with the following mass fractions: sponge titanium 93.5%, crystalline silicon 6.5%;

[0040] The purity of the sponge titanium is ≥99.6%, and the purity of the crystalline silicon is ≥99.68%.

[0041] The preparation method of the titanium-silicon alloy target of this embodiment includes the following steps:

[0042] (1) Mixing: the sponge titanium (particle size is 1mm) and crystalline silicon (particle size size is 2mm) are uniformly mixed with a three-dimensional mixer, and the mixing time is 5min;

[0043] (2) Electrode pressing: Use a 630-ton hydraulic press to press the evenly mixed raw materials into electrode rods with a diameter of 35×45×380mm, each electrode rod is 2.5kg; keep the temperature in a 90°C oven for 3.5h.

[0044] (3) One-time consumable smelting: use a argon arc welding machine in a protective atmosphere to weld an appropriate number of electrode rods in step (2) ...

Embodiment 2

[0050] The titanium-silicon alloy target of the present invention is made of the following raw materials in atomic percentage: 87.5% of titanium sponge and 12.5% of crystalline silicon;

[0051] The purity of the sponge titanium is ≥99.6%, and the purity of the crystalline silicon is ≥99.68%.

[0052] The preparation method of the titanium-silicon alloy target of this embodiment includes the following steps:

[0053] (1) Mixing: the titanium sponge (particle size is 10mm) and the crystalline silicon (the size is 6mm) are uniformly mixed with a three-dimensional mixer, and the mixing time is 8min;

[0054] (2) Electrode pressing: Use a 630-ton hydraulic press to press the evenly mixed raw materials into electrode rods with a diameter of 35 × 50 × 380 mm, each electrode rod is 2.8 kg; keep the temperature in a 100 ℃ oven for 4 hours.

[0055] (3) One-time consumable smelting: use a argon arc welding machine in a protective atmosphere to weld an appropriate number of electrode...

Embodiment 3

[0061] The titanium-silicon alloy target of the present invention is made of the following raw materials in atomic percentage: 80% of titanium sponge and 20% of crystalline silicon;

[0062] The purity of the sponge titanium is ≥99.6%, and the purity of the crystalline silicon is ≥99.68%.

[0063] The preparation method of the titanium-silicon alloy target of this embodiment includes the following steps:

[0064] (1) Mixing: the sponge titanium (particle size is 8mm) and crystalline silicon (size is 6mm) are uniformly mixed with a three-dimensional mixer, and the mixing time is 10min;

[0065] (2) Electrode pressing: Use a 630-ton hydraulic press to press the evenly mixed raw materials into electrode rods with a diameter of 35×60×380mm, each electrode rod is 4.5kg; keep the temperature in a 110°C oven for 6h.

[0066] (3) One-time consumable smelting: use a argon arc welding machine in a protective atmosphere to weld an appropriate number of electrode rods in step (2) in an e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com