Magnetic material and preparation method thereof

A technology of magnetic materials and waste, applied in the direction of magnetic materials, magnetic objects, inorganic materials, etc., can solve the problem of insufficient coercivity of materials, and achieve the effect of improving magnetic properties, high social value, and improving the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

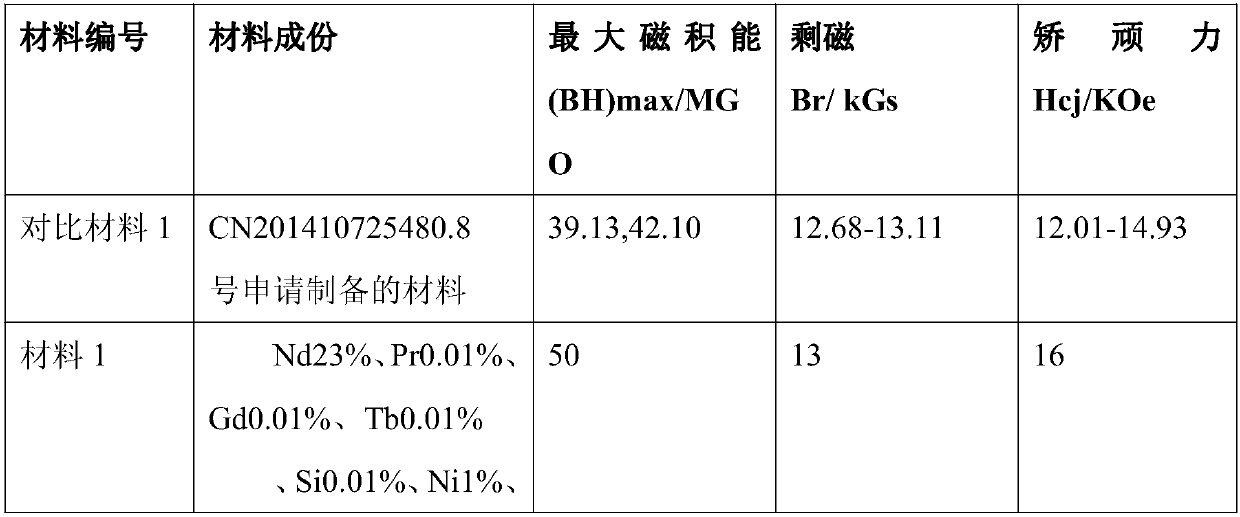

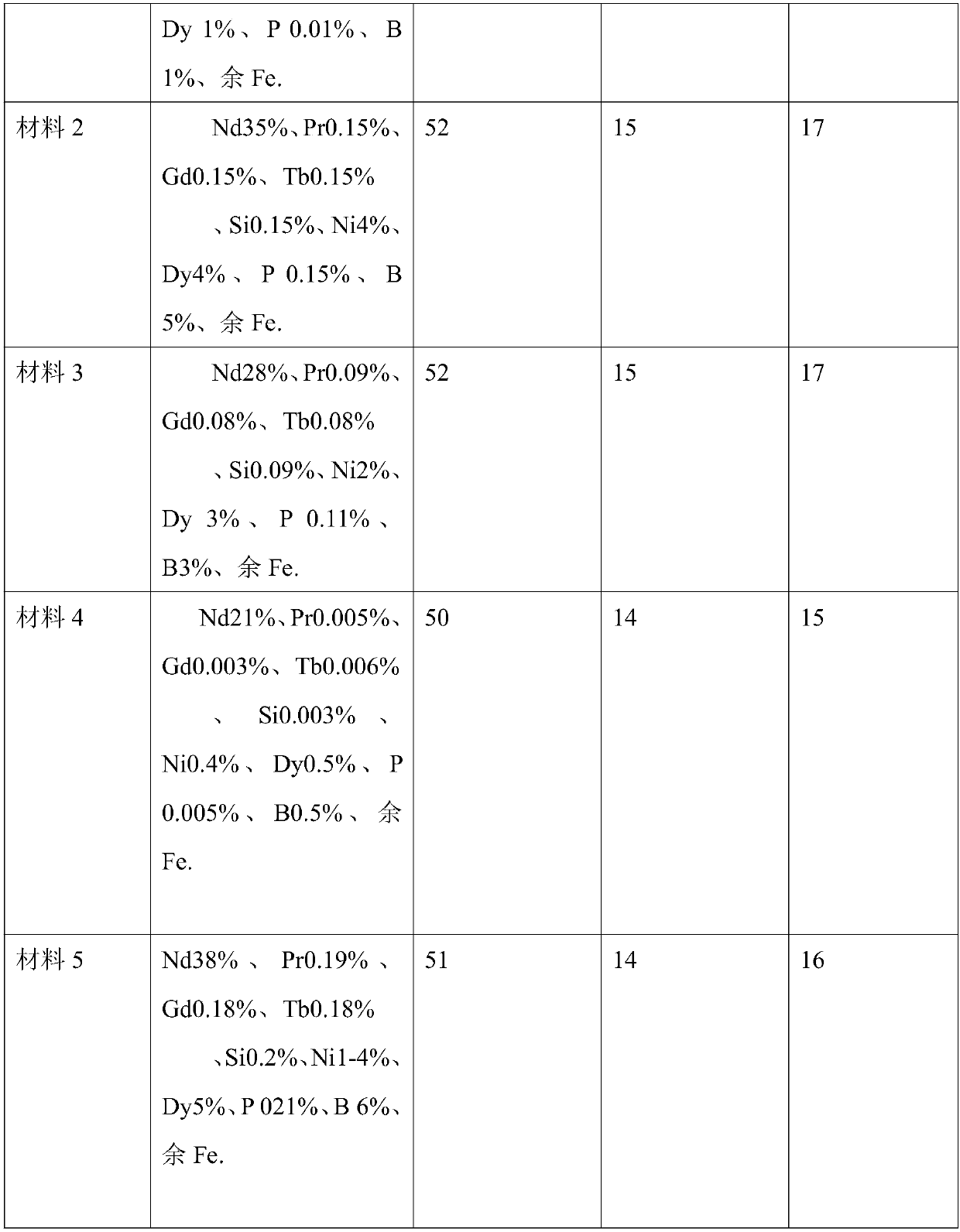

Examples

Embodiment 1

[0028] A magnetic material, the magnetic material is prepared by the following method:

[0029] 1) Put phosphor powder waste and permanent magnet waste in a roasting furnace at 500°C for pretreatment; the weight ratio of phosphor powder waste to permanent magnet waste is 1:1. The milled waste was mixed with Na 2 CO 3 mixed and treated at 680°C for 2 hours, where Na 2 CO 3 The mass ratio of the roasted fluorescent powder waste is 4:1; add hydrochloric acid to the obtained reaction product, and the mass ratio of the reaction product to hydrochloric acid is 1:1; put the prepared mixed solution into a 70°C constant temperature water bath Heating for 2 hours, then filtering to obtain a leach solution containing rare earth elements; mixing 121g / L oxalic acid solution with the leach solution to precipitate compounds, the amount of oxalic acid solution is 35-45% of the mass of the roasted waste, and washing the precipitated compounds with water After 3-5 times, collect the precipi...

Embodiment 2

[0034] A magnetic material, the magnetic material is prepared by the following method:

[0035] 1) Put phosphor powder waste and permanent magnet waste in a roasting furnace at 650°C for pretreatment; the weight ratio of phosphor powder waste to permanent magnet waste is 1:2. The milled waste was mixed with Na 2 CO 3 Mix and treat at 680-810°C for 4 hours, where Na 2 CO 3 The mass ratio of the roasted fluorescent powder waste is 4:1-1.5; add hydrochloric acid to the obtained reaction product, and the mass ratio of the reaction product to hydrochloric acid is 2:1; put the prepared mixed solution into 80°C constant temperature water Heated in the bath for 3h, then filtered to obtain a leachate containing rare earth elements; the compound was precipitated after mixing the oxalic acid solution of 121g / L with the leachate, and the amount of the oxalic acid solution was 45% of the mass of the roasted waste material, and the precipitated compound was washed with water After 3-5 t...

Embodiment 3

[0040] A magnetic material, the magnetic material is prepared by the following method:

[0041] 1) Put phosphor powder waste and permanent magnet waste in a roasting furnace at 600°C for pretreatment; the weight ratio of phosphor powder waste to permanent magnet waste is 1:2. The milled waste was mixed with Na 2 CO 3 mixed and treated at 800°C for 4 hours, where Na 2 CO 3 The mass ratio of the roasted fluorescent powder waste is 4:1.5; add hydrochloric acid to the obtained reaction product, and the mass ratio of the reaction product to hydrochloric acid is 2:1; put the prepared mixed solution into a constant temperature water bath at 80°C Heating for 3h, then filtering to obtain a leach solution containing rare earth elements; the oxalic acid solution of 121g / L is mixed with the leach solution to separate out the compound, the amount of the oxalic acid solution is 45% of the quality of the waste material of the roasting treatment, and the precipitated compound is washed wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com