Magnetic material containing nitrogen-boron composite phase and preparation method

A technology of magnetic materials and composite phases, applied in the direction of magnetic materials, magnetic objects, inorganic materials, etc., can solve the problem of insufficient magnetic induction intensity, achieve good stability and practicability, flexible composition ratio, and improve the effect of the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

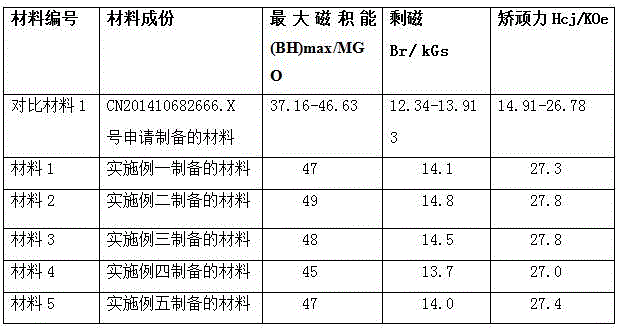

Examples

Embodiment 1

[0034] The preparation method of nitrogen-boron composite phase magnetic material of the present invention, the method comprises the following steps:

[0035] 1) Waste disposal:

[0036] First place the phosphor waste in a roasting furnace for pretreatment at a temperature of 650°C. The treatment temperature and holding time are 2 hours. After cooling, the waste is ball milled to 20-80 microns to obtain the pretreatment waste; then the pretreatment waste is added to a concentration of 7mol / L of hydrochloric acid, then add mass concentration of 30% hydrogen peroxide, and keep warm at 95°C for 2 hours; the mass volume ratio of pretreatment waste to hydrochloric acid is 1.5kg / L, and the mass volume ratio of pretreatment waste to hydrogen peroxide is 0.3kg / L; then soaked with water for 5 times to obtain acid-soluble slag for later use; take acid-soluble slag and mix evenly with a mass fraction of 15% Na2CO3, roast at 1000°C for 2 hours, and then treat with 4mol / L hydrochloric ac...

Embodiment 2

[0045] The preparation method of nitrogen-boron composite phase magnetic material of the present invention, the method comprises the following steps:

[0046] 1) Waste disposal:

[0047] First place the phosphor powder waste in a roasting furnace for pretreatment at a temperature of 500°C. The treatment temperature and holding time are 1 hour. After cooling, ball mill to 20-80 microns to obtain the pretreated waste; then add the pretreated waste to a concentration of 4 -7mol / L of hydrochloric acid, then add mass concentration of 30% hydrogen peroxide, and incubate at 95°C for 2 hours; the mass volume ratio of pretreatment waste to hydrochloric acid is 1.3kg / L, and the mass volume ratio of pretreatment waste to hydrogen peroxide is 0.2kg / L; then soaked with water for 3 times to obtain acid soluble slag for later use; take acid soluble slag and (mass fraction: 10%) Na2CO3, mix evenly, roast at 1000°C for 2h, and then treat with 4mol / L hydrochloric acid, The mass ratio of acid s...

Embodiment 3

[0056] This example prepares nitrogen-boron composite phase magnetic material alloy ingot: ingredients are prepared according to the following mass percentages: Nd28%, Y2.8%, Eu4.2%, Ce1.4%, Tb1.4%, B3%, P0.4% , Ba0.2%, V0.50%, and the rest is Fe. All the other preparation conditions and processes are the same as in Example 1. The mass percent content of N in the material is 0.65%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com