A kind of piezoelectric functional porous electrode composite material and its preparation method

A composite material and multi-functional technology, applied in the manufacture/assembly of piezoelectric/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, circuits, etc., can solve the cumbersome process and the piezoelectric performance needs to be improved and other problems to achieve the effect of simple process, strong structure and flexible composition ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] A method for preparing a piezoelectric functional porous electrode composite material. The material preparation process includes the following steps:

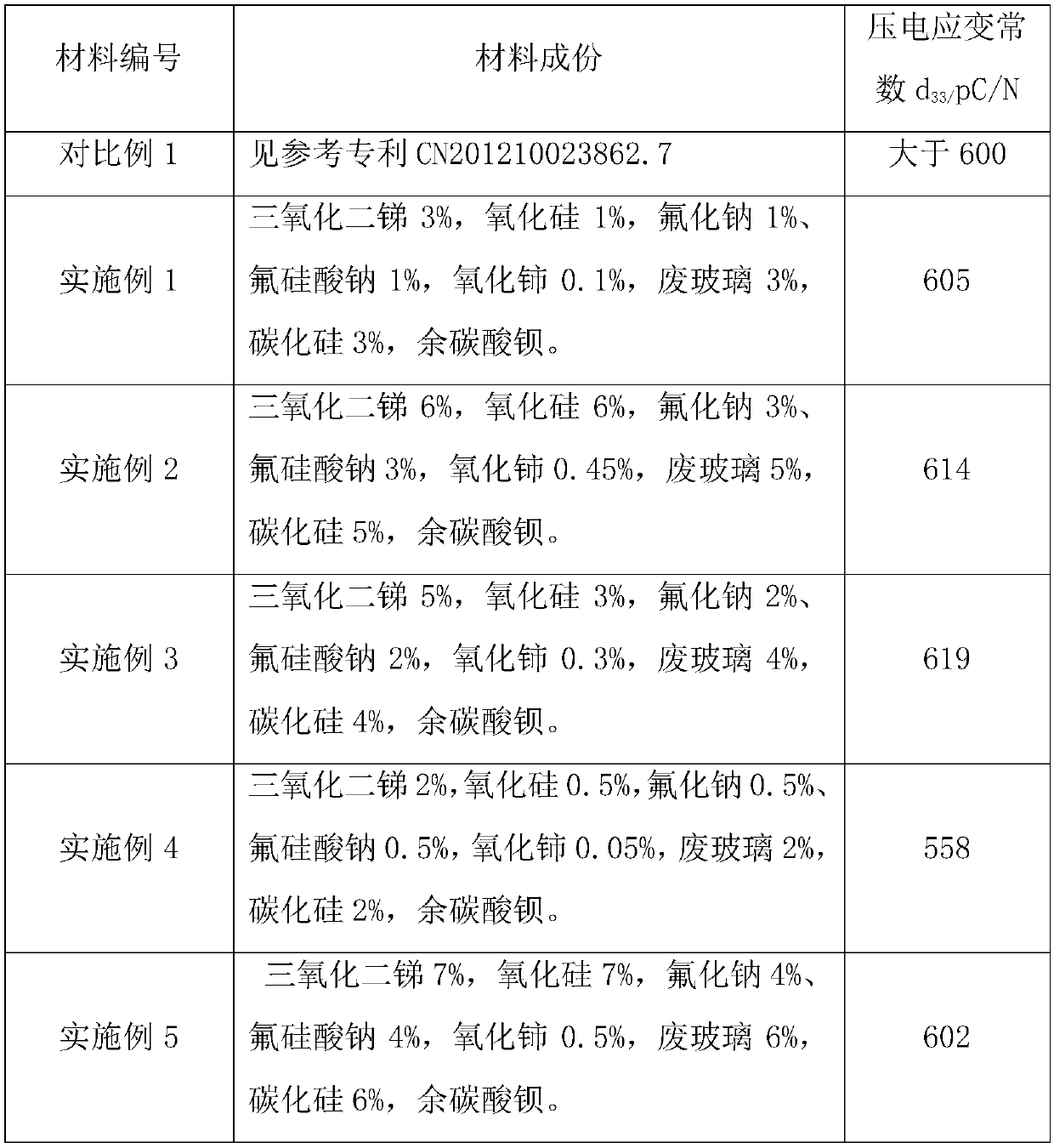

[0029] (a) According to the mass percentage of material composition: antimony trioxide 3-6%, silicon oxide 1-6%, sodium fluoride 1-3%, sodium fluorosilicate 1-3%, cerium oxide 0.1-0.45%, 3-5% of waste glass, 3-5% of silicon carbide, and the balance of barium carbonate are used for batching and mixing.

[0030] (b) Put the mixed powder sample into a ball mill for ball milling for 48 hours to make the powder evenly mixed;

[0031] (c) squeeze the ground powder tightly into a cylindrical mold, place it on a tablet press for pressing, and the pressure of the tablet press is 100MPa;

[0032] (d) put the pressed sample into a resistance furnace for sintering, the sintering temperature is 1200-1300° C., the holding time is 50-60 minutes, and the sample is taken out after naturally cooling to room temperature;

[0033] (e) Aft...

Embodiment 1

[0037] The mass percentage of material composition is: 3% antimony trioxide, 1% silicon oxide, 1% sodium fluoride, 1% sodium fluorosilicate, 0.1% cerium oxide, 3% waste glass, 3% silicon carbide, and the balance is carbonic acid barium.

Embodiment 2

[0039] The mass percentage of material composition is: antimony trioxide 6%, silicon oxide 6%, sodium fluoride 3%, sodium fluorosilicate 3%, cerium oxide 0.45%, waste glass 5%, silicon carbide 5%, and the balance is carbonic acid barium.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com