A kind of mg-mn master alloy and preparation method thereof

A master alloy, mg-mn technology, applied in the field of metal materials, can solve the problems of small Mn diffusion coefficient, reduced refinement effect of master alloy, uneven distribution of Mn, etc., to achieve uniform distribution, avoid violent oxidation, and achieve good refinement effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

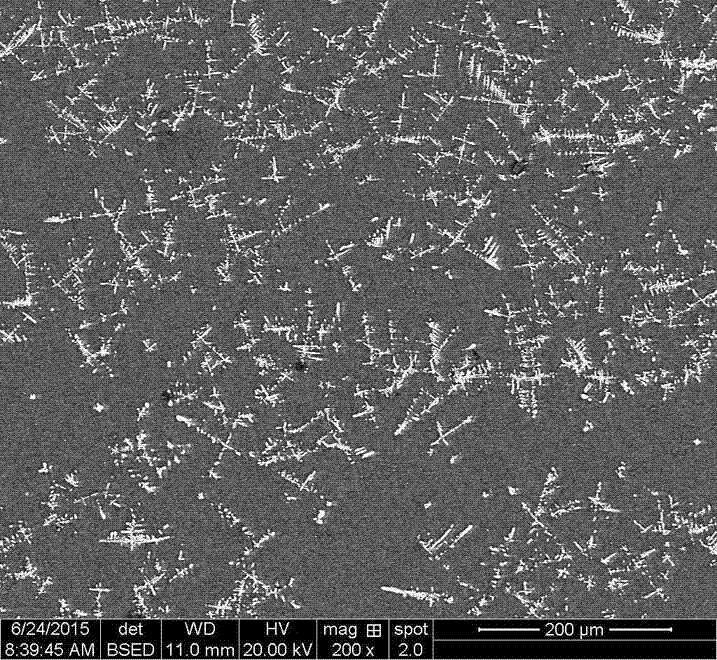

Embodiment 1

[0022] (1) Weigh the raw materials according to the mass percentage of industrial pure magnesium 95% and pure manganese 5%;

[0023] (2) Put Mg and Mn into the crucible at the same time, raise the furnace temperature to 680~700°C, wait until the Mg is completely melted, cover the surface of the melt with a layer of protective solvent with a thickness of 3~8mm, and raise the temperature to 820~950°C , keep warm for 10~20min;

[0024] (3) Direct casting, which can be cast into ingots or prepared into bars.

[0025] In the Mg-Mn master alloy prepared according to the above-mentioned proportion and process, the mass percentage of Mn is 5.3-5.7%.

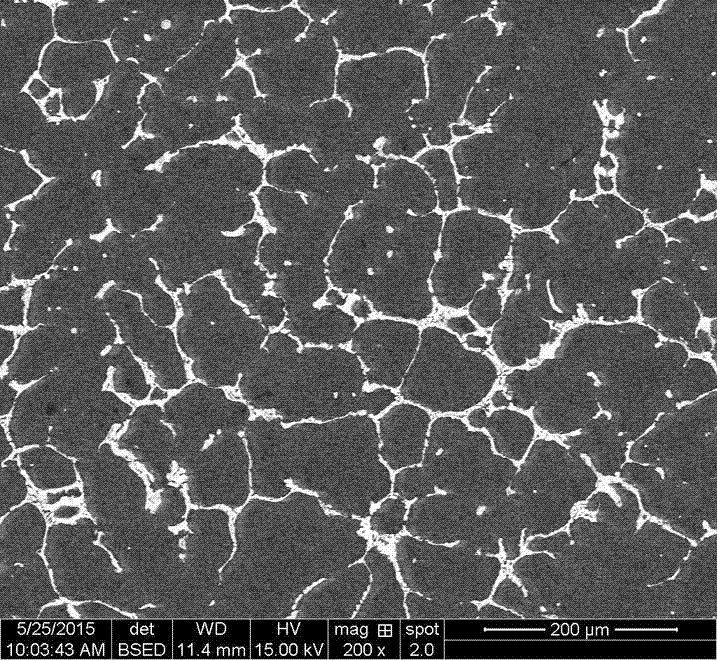

Embodiment 2

[0027] (1) Weigh the raw materials according to the mass percentage of industrial pure magnesium 90% and pure manganese 10%;

[0028] (2) Put Mg and Mn into the crucible at the same time, use an intermediate frequency furnace to completely melt Mg with a frequency of 170~250HZ, cover the surface of the melt with a layer of protective solvent with a thickness of 4~9mm, and use a frequency of 250~350HZ to raise the temperature To 900~1000℃, keep warm for 20~30min;

[0029] (3) Direct casting, which can be cast into ingots or prepared into bars.

[0030] In the Mg-Mn master alloy prepared according to the above-mentioned proportion and process, the mass percentage of Mn is 10.2-10.9%.

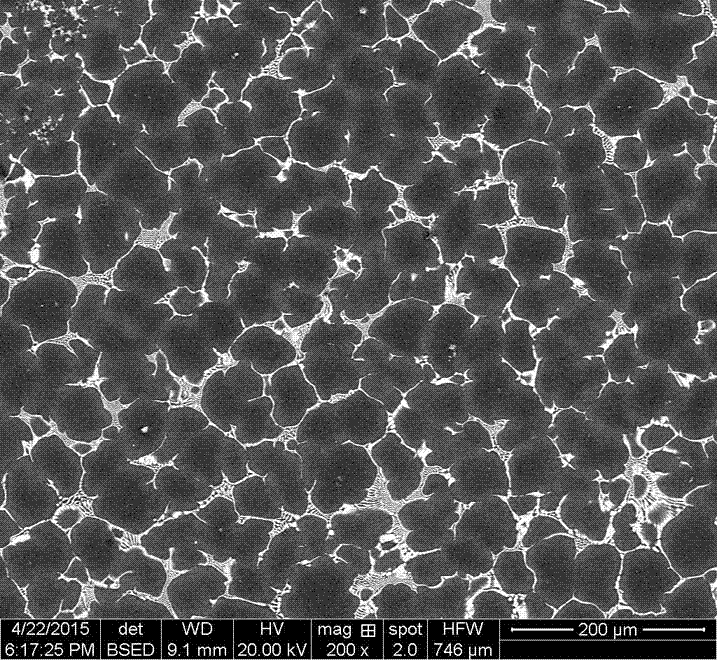

Embodiment 3

[0032] (1) Weigh the raw materials according to the mass percentage of 85% industrial pure magnesium and 15% pure manganese;

[0033] (2) Put Mg and Mn into the crucible at the same time, use an intermediate frequency furnace to completely melt Mg with a frequency of 170~250HZ, cover the surface of the melt with a layer of protective solvent with a thickness of 5~9mm, and use a frequency of 300~350HZ to raise the temperature To 900~1000℃, keep warm for 30~40min;

[0034] (3) Direct casting, which can be cast into ingots or prepared into bars.

[0035] In the Mg-Mn master alloy prepared according to the above-mentioned proportion and process, the mass percentage of Mn is 15.4-16.1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com