Functional material and preparation method

A functional material, mass percentage technology, applied in the direction of magnetic materials, inorganic material magnetism, magnetic objects, etc., can solve the problem of insufficient magnetic induction intensity, and achieve the effects of good practicability, cost reduction, and high social value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

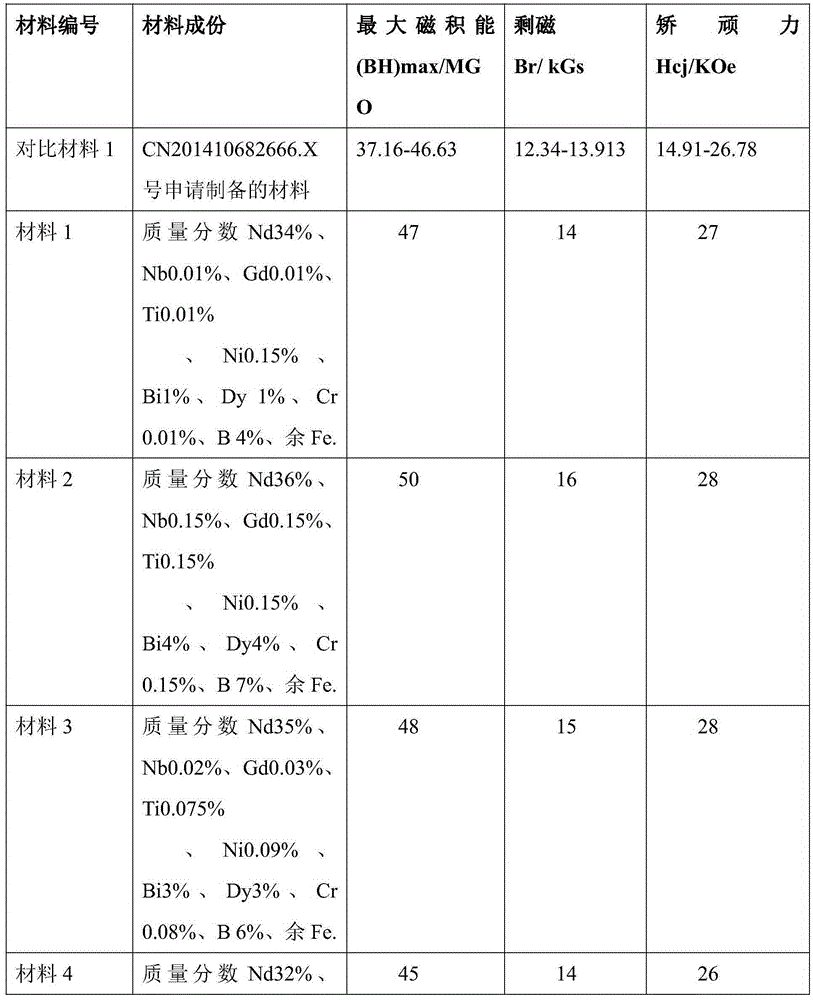

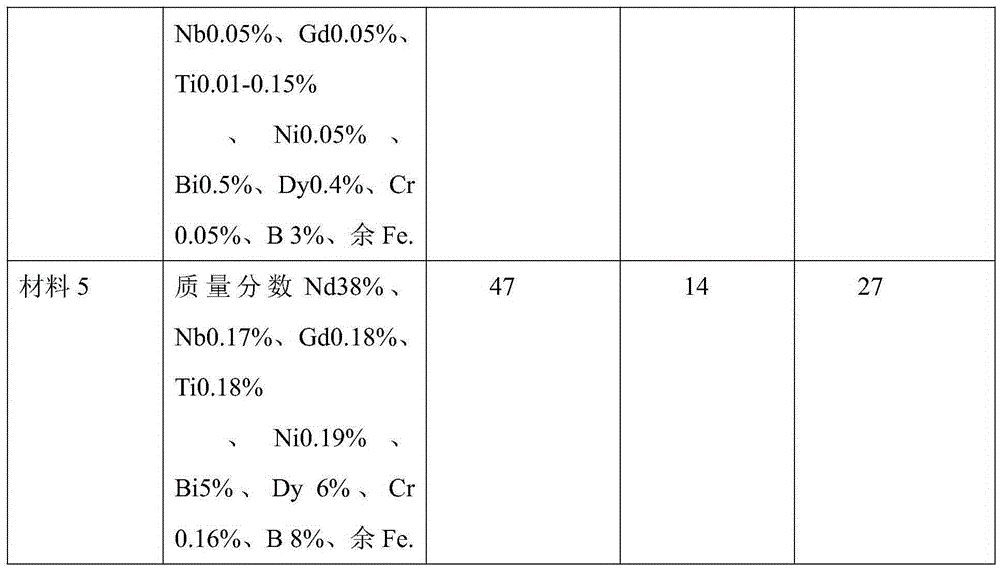

Embodiment 1

[0018] A preparation method of multiple rare earth phase materials, comprising the following steps:

[0019] 1) Dosing according to the following mass percentages: Nd34%, Nb0.01%, Gd0.01%, Ti0.01%, Ni0.15%, Bi1%, Dy1%, Cr0.01%, B4%, and Fe;

[0020] 2) Add the prepared raw materials above into a vacuum induction furnace to melt an alloy ingot, and the vacuum degree of the electric furnace is required to be less than 0.1Pa. Then put the obtained alloy ingot into the remelting tubular crucible in the vacuum induction forming furnace for remelting. The remelting temperature is 1600-1670°C. At 2-4mm above the rim, put the above alloy ingot in a tubular crucible and melt it. After the alloy is melted, it will be sprayed out from the hole at the bottom of the crucible under the action of argon and contact with the edge of the rotating runner to form a thickness of 770-780μm. , Alloy strip with a width of 13-15mm, the rotational speed of the runner rim is 20-24m / s.

[0021] 3) Put ...

Embodiment 2

[0023] A preparation method of multiple rare earth phase materials, comprising the following steps:

[0024] 1) Dosing according to the following mass percentage: Nd36%, Nb0.15%, Gd0.15%, Ti0.15%, Ni0.15%, Bi4%, Dy4%, Cr0.15%, B7%, remaining Fe;

[0025] 2) Add the prepared raw materials above into a vacuum induction furnace to melt an alloy ingot, and the vacuum degree of the electric furnace is required to be less than 0.1Pa. Then put the obtained alloy ingot into the remelting tubular crucible in the vacuum induction forming furnace for remelting. The remelting temperature is 1600-1670°C. At 2-4mm above the rim, put the above alloy ingot in a tubular crucible and melt it. After the alloy is melted, it will be sprayed out from the hole at the bottom of the crucible under the action of argon and contact with the edge of the rotating runner to form a thickness of 770-780μm. , Alloy strip with a width of 13-15mm, the rotational speed of the runner rim is 20-24m / s.

[0026] 3)...

Embodiment 3

[0028] A preparation method of multiple rare earth phase materials, comprising the following steps:

[0029] 1) Dosing according to the following mass percentages: Nd35%, Nb0.02%, Gd0.03%, Ti0.075%, Ni0.09%, Bi3%, Dy3%, Cr0.08%, B6%, and Fe;

[0030] 2) Add the prepared raw materials above into a vacuum induction furnace to melt an alloy ingot, and the vacuum degree of the electric furnace is required to be less than 0.1Pa. Then put the obtained alloy ingot into the remelting tubular crucible in the vacuum induction forming furnace for remelting. The remelting temperature is 1600-1670°C. At 2-4mm above the rim, put the above alloy ingot in a tubular crucible and melt it. After the alloy is melted, it will be sprayed out from the hole at the bottom of the crucible under the action of argon and contact with the edge of the rotating runner to form a thickness of 770-780μm. , Alloy strip with a width of 13-15mm, the rotational speed of the runner rim is 20-24m / s.

[0031] 3) Put...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com