Ultrasonic-assisted semi-solid welding method of aluminum alloy and magnesium alloy

An ultrasonic-assisted, welding method technology, applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of low welding efficiency and high welding temperature, achieve the effect of improving welding efficiency, eliminating intermetallic compounds, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

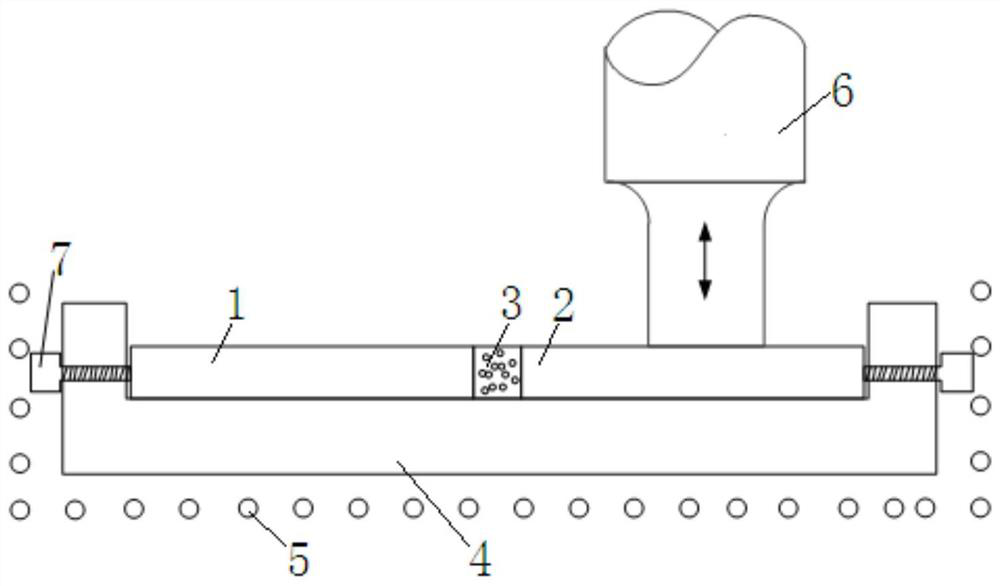

[0027] Specific implementation mode 1: This implementation mode is an ultrasonic-assisted semi-solid welding method of aluminum alloy and magnesium alloy, which is specifically completed according to the following steps:

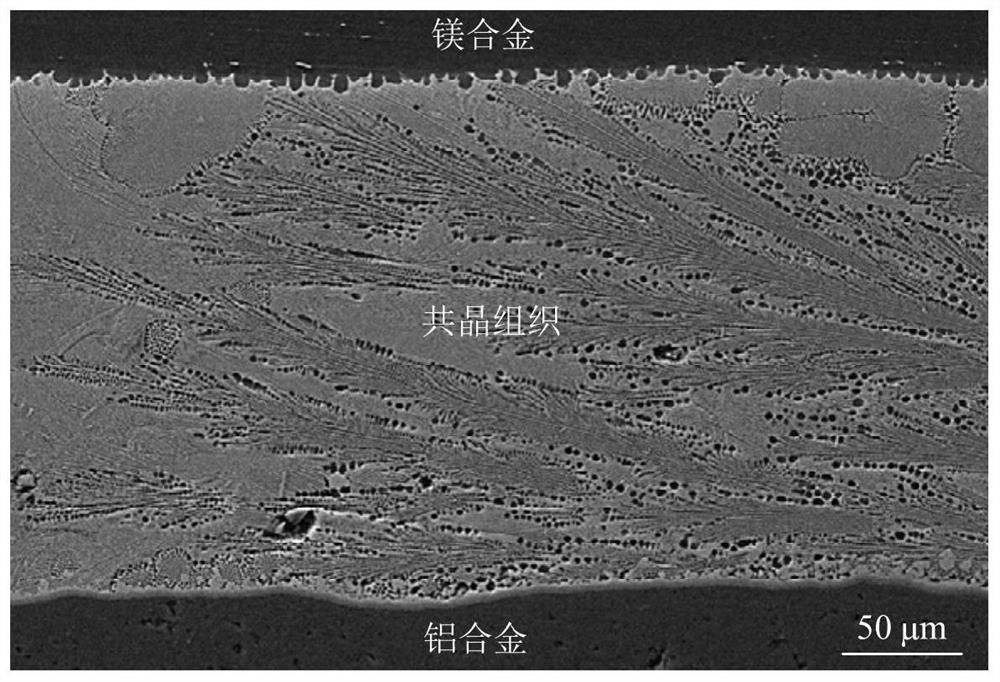

[0028] 1. Selection of solder components: The selection principle of solder components is not to react with magnesium or aluminum to form hard and brittle intermetallic compounds;

[0029] 2. Brazing material preparation: According to the alloy phase diagram, according to the solder composition in step 1, the difference between the solid-liquid phase interval endpoints of the solder is not less than 20°C to determine the solder composition, and prepare the solder, and the welding temperature is at the brazing temperature. The solid-liquid phase interval of the material is selected to obtain the solder;

[0030] 3. Pretreatment: Use sandpaper and ultrasonic waves to grind and clean the surfaces of aluminum alloy and magnesium alloy respectively, and then plac...

specific Embodiment approach 2

[0039]Embodiment 2: The difference between this embodiment and Embodiment 1 is that the solder described in step 1 is Sn-Zn solder or Zn-Al-based solder. Others are the same as the first embodiment.

specific Embodiment approach 3

[0040] Specific embodiment three: the difference between this embodiment and specific embodiment two is: in step two, when the solder is Sn-Zn solder, and the Sn-Zn solder is Sn-30Zn, the welding temperature is 200-300°C ; When the solder is Zn-Al-based solder, and the Zn-Al-based solder is Zn-20Al, the welding temperature is 420-470°C. Others are the same as in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com