Power soft package lithium battery filling machine

A soft-pack lithium battery and liquid injection machine technology, which is applied in the field of liquid injection machines, can solve the problems of unreasonable use of production space, unfavorable saving of production costs, and reduction of production costs, achieving compact structure, less production space, and reduced production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to describe the technical content, structural features, and achieved effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

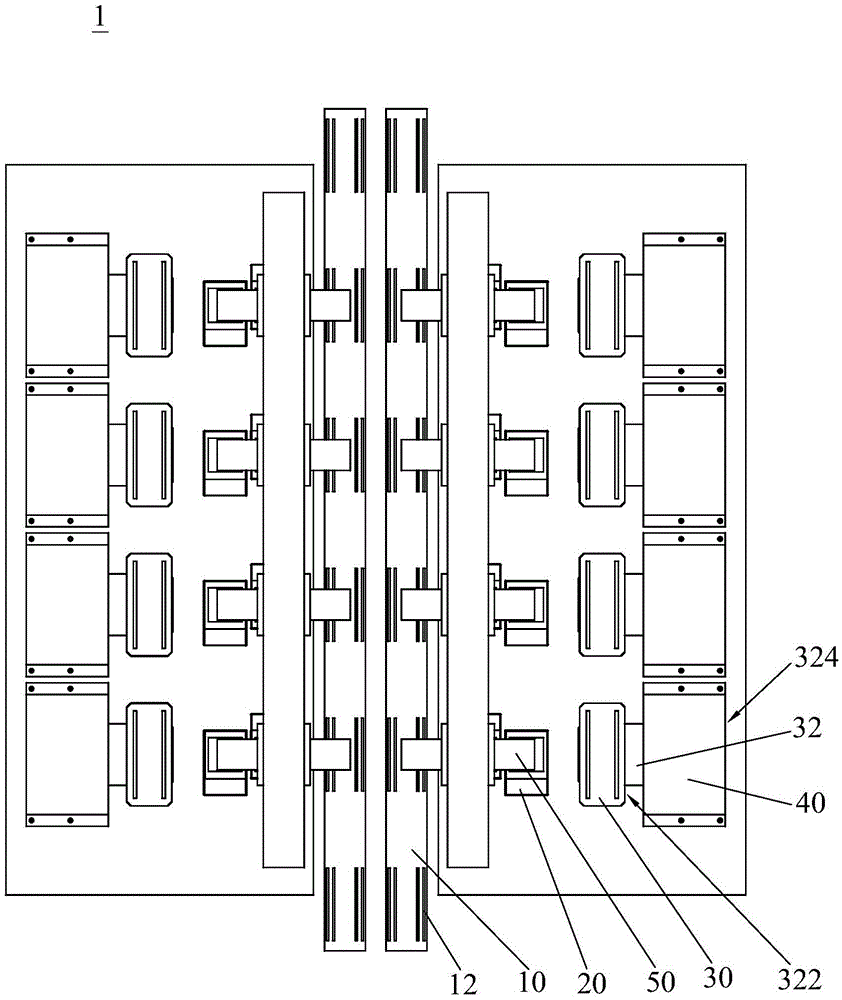

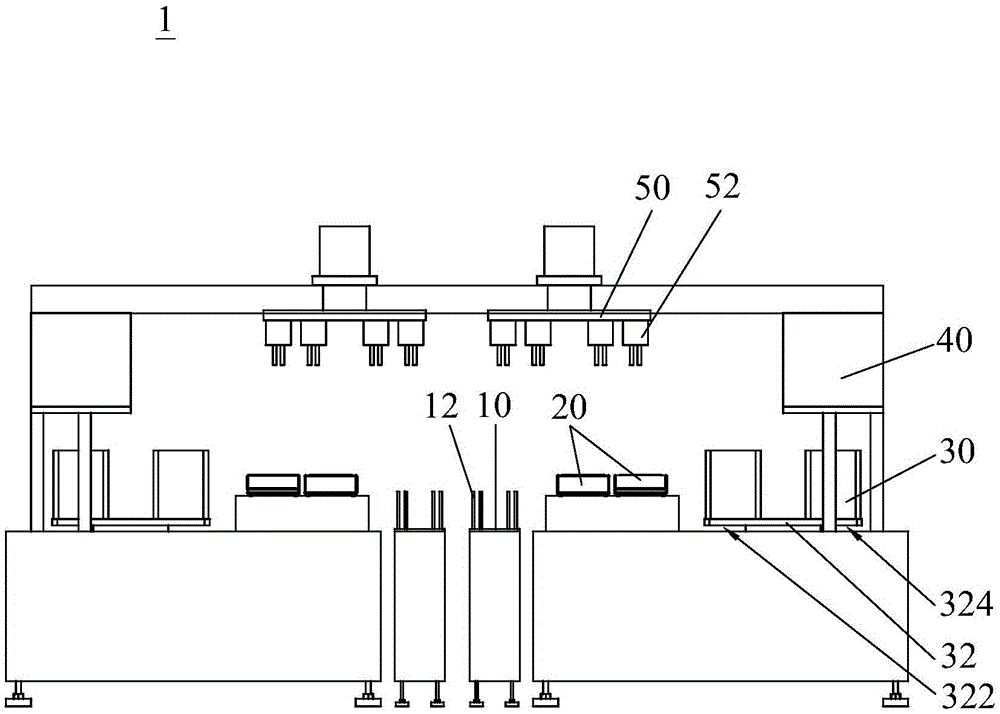

[0014] Such as figure 1 and 2 As shown, the power soft pack lithium battery liquid injection machine 1 includes a conveyor belt 10 , a weighing and code scanning mechanism 20 , a liquid injection fixture 30 , a vacuum liquid injection chamber 40 and a rotating mobile manipulator 50 . The weighing and code scanning mechanism 20 weighs and scans the power soft-pack lithium battery (not shown) to be injected and the injected power soft-pack lithium battery (not shown), and the vacuum liquid injection chamber 40 injects the power soft-pack lithium battery in the liquid injection fixture 30. liquid, rotating and moving the manipulator 50 between the conveyor belt 10, the weighing scanning code mechanism 20 and the liquid injection fixture 30 to rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com