Composite sodium-storage positive electrode for solid-state secondary sodium battery and preparation method for composite sodium-storage positive electrode

A composite sodium storage and solid-state technology, applied in secondary batteries, battery electrodes, circuits, etc., can solve problems such as potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 0.3gNaMnO 2 , 0.3gNaPF 6 Solution, 0.3g acetylene black, 0.1g PVDF-HFP were uniformly mixed in 10g acetone solution, and stirred continuously at 50°C for 4 hours to obtain a uniform sol-state liquid;

[0031] The homogeneous sol-state liquid in (1) is evenly coated on the β”-Al by screen printing. 2 o 3 On the surface of the electrolyte, the thickness of the electrolyte is 170 microns, and after drying, a solid-state composite sodium storage positive electrode layer in close contact with the electrolyte is obtained, with a thickness of 60 microns;

[0032] A metal sodium sheet was pressed on the other side of the sodium ion-conducting ceramic electrolyte layer to a thickness of 70 μm. Encapsulate the solid-state battery in a button battery to obtain a high-specific-energy solid-state secondary sodium battery that operates at room temperature;

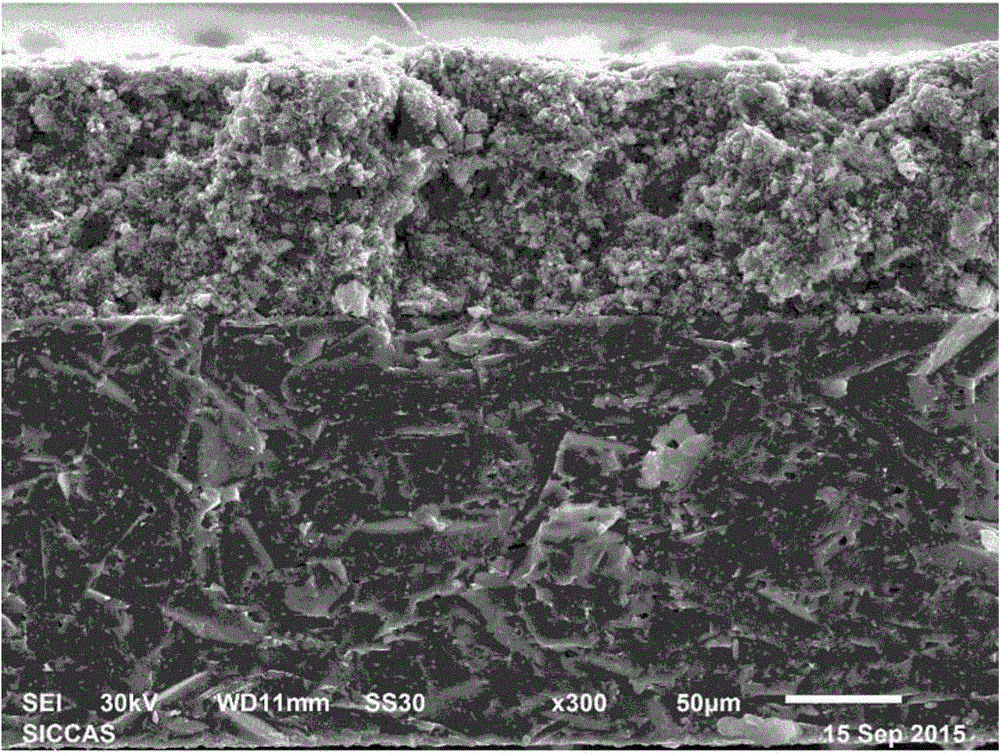

[0033] figure 1 The scanning electron micrograph of the interface between the solid-state composite sodium-storage positiv...

Embodiment 2

[0035] 0.3gNaTi 2 (PO 4 ) 3 , 0.3gNaClO 4 Solution, 0.3g acetylene black, 0.1g PVDF-HFP were uniformly mixed in 10g acetone solution, and stirred continuously at 50°C for 4 hours to obtain a uniform sol-state liquid;

[0036] The homogeneous sol-state liquid in (1) is evenly coated on the β”-Al by screen printing. 2 o 3 On the surface of the electrolyte, after drying, a solid-state composite sodium storage positive electrode layer in close contact with the electrolyte is obtained, with a thickness of 52 microns;

[0037] A metal sodium sheet was pressed on the other side of the sodium ion-conducting ceramic electrolyte layer to a thickness of 70 μm. Encapsulate the solid-state battery in a button battery to obtain a high-specific-energy solid-state secondary sodium battery that operates at room temperature;

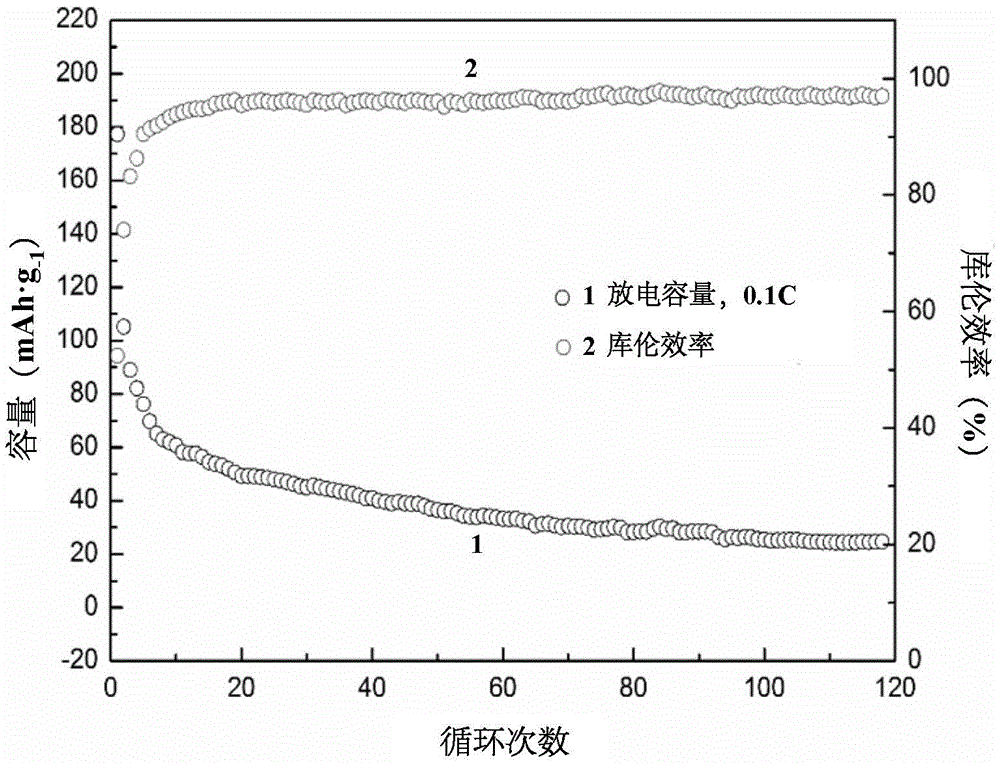

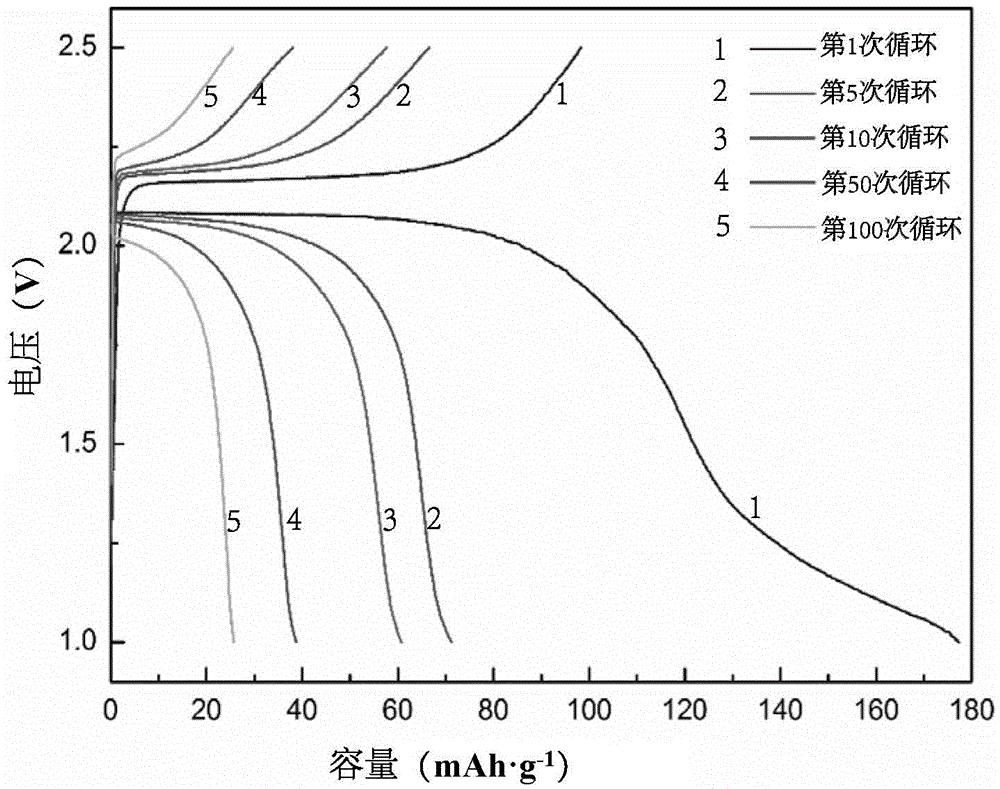

[0038] figure 2 The capacity-cycle curve of the room-temperature operating solid-state secondary sodium battery prepared for Example 2 of the present invention du...

Embodiment 3

[0040] 0.85gNaTi 2 (PO 4 ) 3 , 0.05gNaClO 4 Solution, 0.05g acetylene black, 0.05g PVDF were uniformly mixed in 10g acetone solution, and stirred continuously at 50°C for 12h to obtain a uniform sol-state liquid;

[0041] The homogeneous sol-state liquid in (1) is evenly coated on the β”-Al by screen printing. 2 o 3 On the surface of the electrolyte, after drying, a solid-state composite sodium storage positive electrode layer in close contact with the electrolyte is obtained, with a thickness of 83 microns;

[0042] A metal sodium sheet was pressed on the other side of the sodium ion-conducting ceramic electrolyte layer to a thickness of 70 μm. Encapsulate the solid-state battery in a button battery to obtain a high-specific-energy solid-state secondary sodium battery operating at room temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com