Greenhouse insulation film control mechanism and its installation method

A technology of control mechanism and installation method, which is applied in the fields of botanical equipment and methods, greenhouse cultivation, climate change adaptation, etc., can solve the problems of heat dissipation and cooling in a greenhouse without a double-layer frame, high degree of sealing, heat dissipation, and poor thermal insulation effect, and saves energy. The effect of manpower, temperature control and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

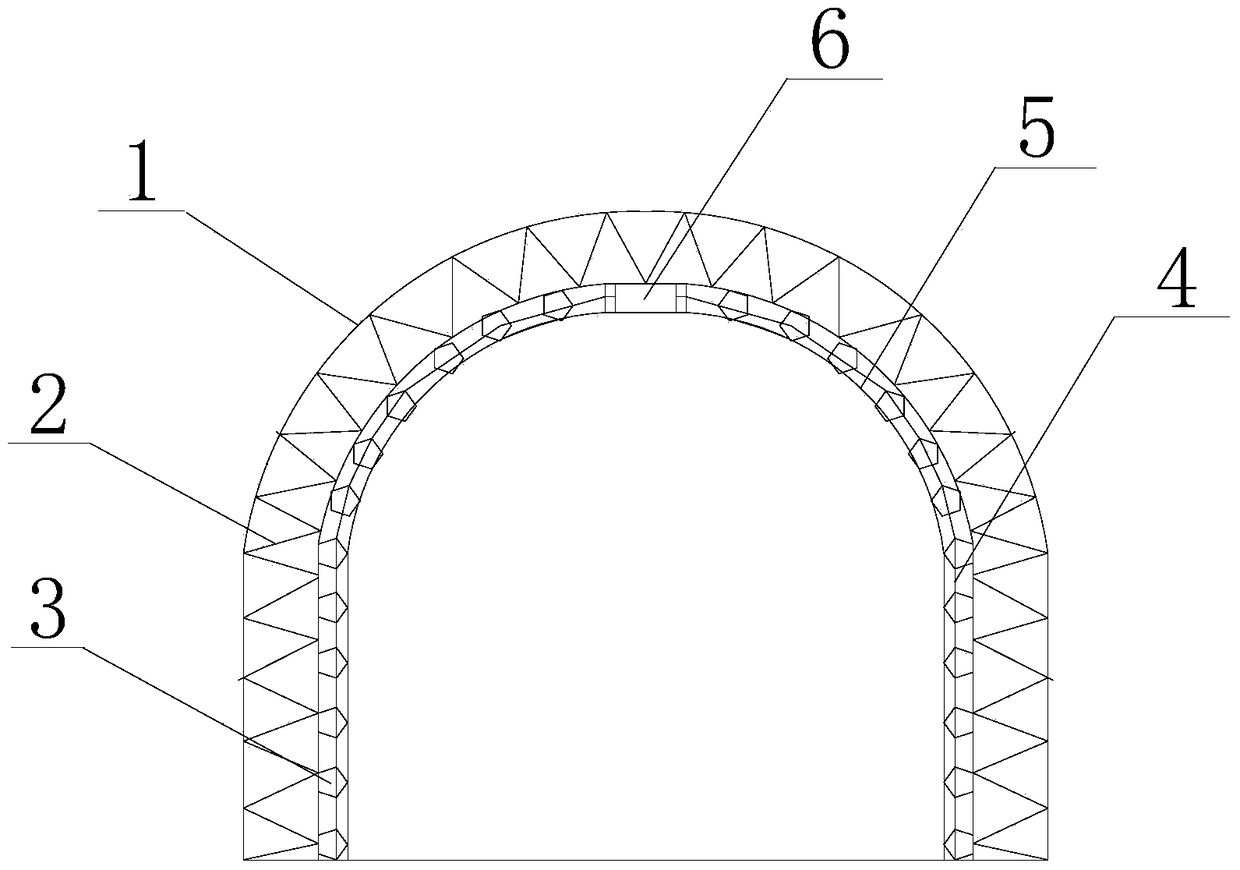

[0026] Such as figure 1 with Figure 4 As shown, a greenhouse insulation film control mechanism, the control mechanism is located inside the double-layer framework 2, the control mechanism includes a controller 6 on the top of the double-layer framework 2 and movable film-hanging devices 3 located on both sides of the double-layer framework 2, the movable hanging The membrane device 3 is closely attached to the double-layer skeleton 2 and arranged at intervals from bottom to top, and the movable membrane device 3 is also fixed with the thermal insulation film 5; the control mechanism controls its movement up and down by stretching the rope 4 on the movable membrane device 3; the thermal insulation film 5 Stretched from the bottom to the top of the greenhouse by the movable film hanging device 3 to form a closed inner membrane space, which together with the outer membrane 1 space of the double-layer skeleton 2 constitutes a two-layer thermal insulation membrane 5 structure.

...

Embodiment 2

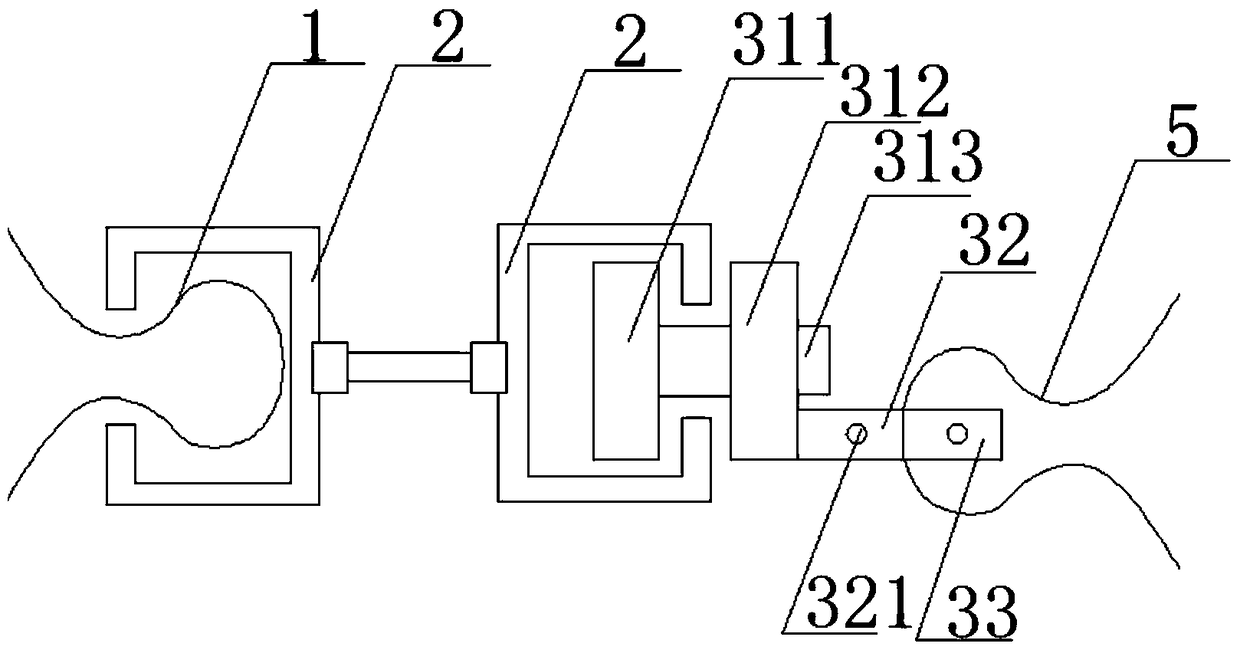

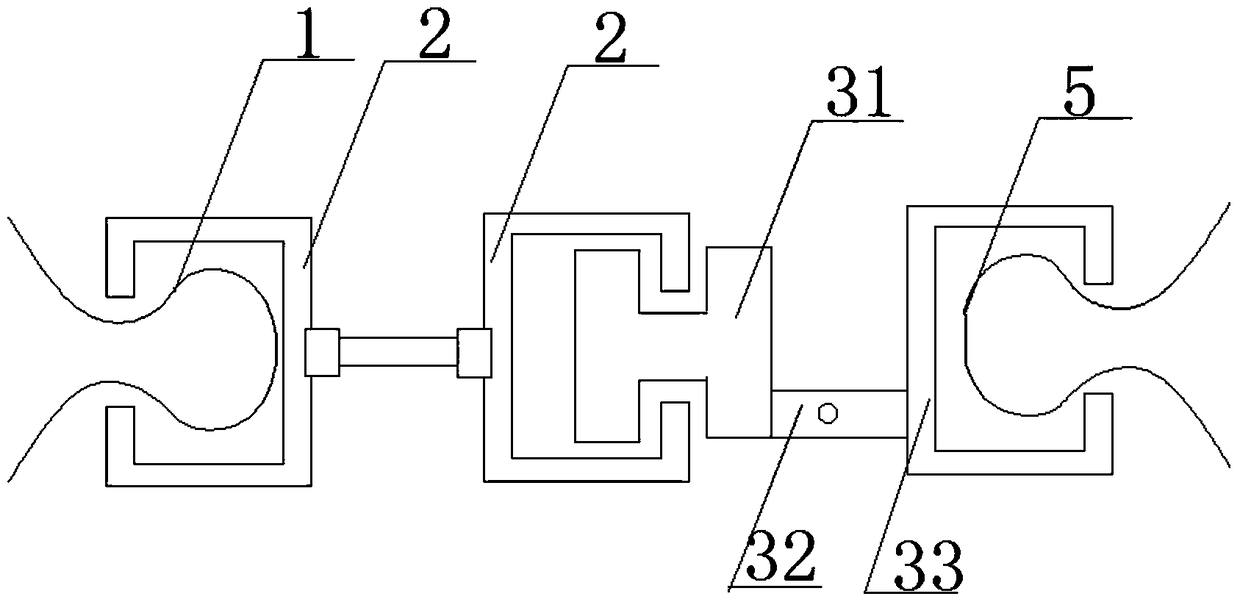

[0041] Such as figure 2 with image 3 As shown, there are multiple connection modes between the movable film hanging device 3 and the thermal insulation film 5 in the present invention. figure 2 In the middle, the mode of direct connection is adopted, by setting the thermal insulation film 5 into a skirt shape in advance, the movable film hanging device 3 can be directly connected with the thermal insulation film 5 through the skirt. The advantage of this method is that it can save materials and is easy to operate. But pull frequently, be easy to cause permanent damage to insulation film 5. image 3 It adopts another indirect connection method, by adding a groove between the movable film hanging device 3 and the thermal insulation film 5, and inserting the thermal insulation film 5 into the groove through the circlip, and the movable film hanging device 3 is directly connected with the groove, That is, an indirect connection is realized. The advantage of this method is t...

Embodiment 3

[0043] In the actual application process, the inner membrane space formed by the thermal insulation membrane 5 has poor sealing performance. Because the thermal insulation film 5 is well sealed with the bottom of the greenhouse, the problem occurs at the top of the greenhouse. In order to ensure that the gap of the top insulation film 5 can be filled after merging, it is usually necessary to superimpose multiple layers of insulation film 5 before installation to prevent the problem of poor contact of the top insulation film 5 and ensure a good sealing effect. . The specific method is to install a rectangular thermal insulation film 5 at 1-5m around the controller 6 at the top, which can be pressed together with the expanded thermal insulation films 5 on both sides or realize top sealing by falling and overlapping.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com