Environment-friendly multi-stage internal-circulation impurity removing system of grain dryer

A grain dryer and internal circulation technology, applied in the direction of drying and preserving seeds, separating solids, and separating solids from solids with airflow, can solve the problem of increasing energy consumption costs of grain drying operations and increasing grain drying The procurement cost of site equipment, the harsh working environment and other issues can achieve the effect of improving the drying effect, easy separation, and realizing the dust removal function.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The content of the present invention will be described below in conjunction with specific embodiments.

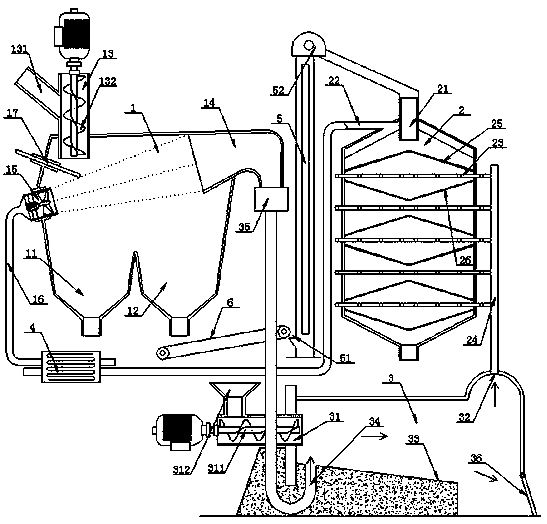

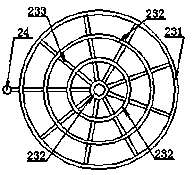

[0025] Such as figure 1 with figure 2 As shown, it is a schematic structural diagram of a multi-stage internal circulation environmental protection impurity removal system for a grain dryer according to the present invention. A multi-stage internal circulation environment-friendly impurity removal system for a grain dryer according to the present invention includes a closed impurity removal mechanism for separating sand, gravel and straw impurities in the grain, a closed drying mechanism for drying the grain, and a closed heating mechanism for supplying heat to the closed drying mechanism;

[0026] The closed impurity removal mechanism includes an impurity removal bin (1), the bottom of the impurity removal bin (1) is provided with a gravel discharge cylinder (11) and a grain discharge cylinder (12), and the impurity removal bin (1) The top is provided with a gra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com