Methacrylaldehyde catalyst

A methacrolein and catalyst technology, which is applied in the direction of physical/chemical process catalysts, carbon-based compound preparation, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of low yield of methacrolein

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

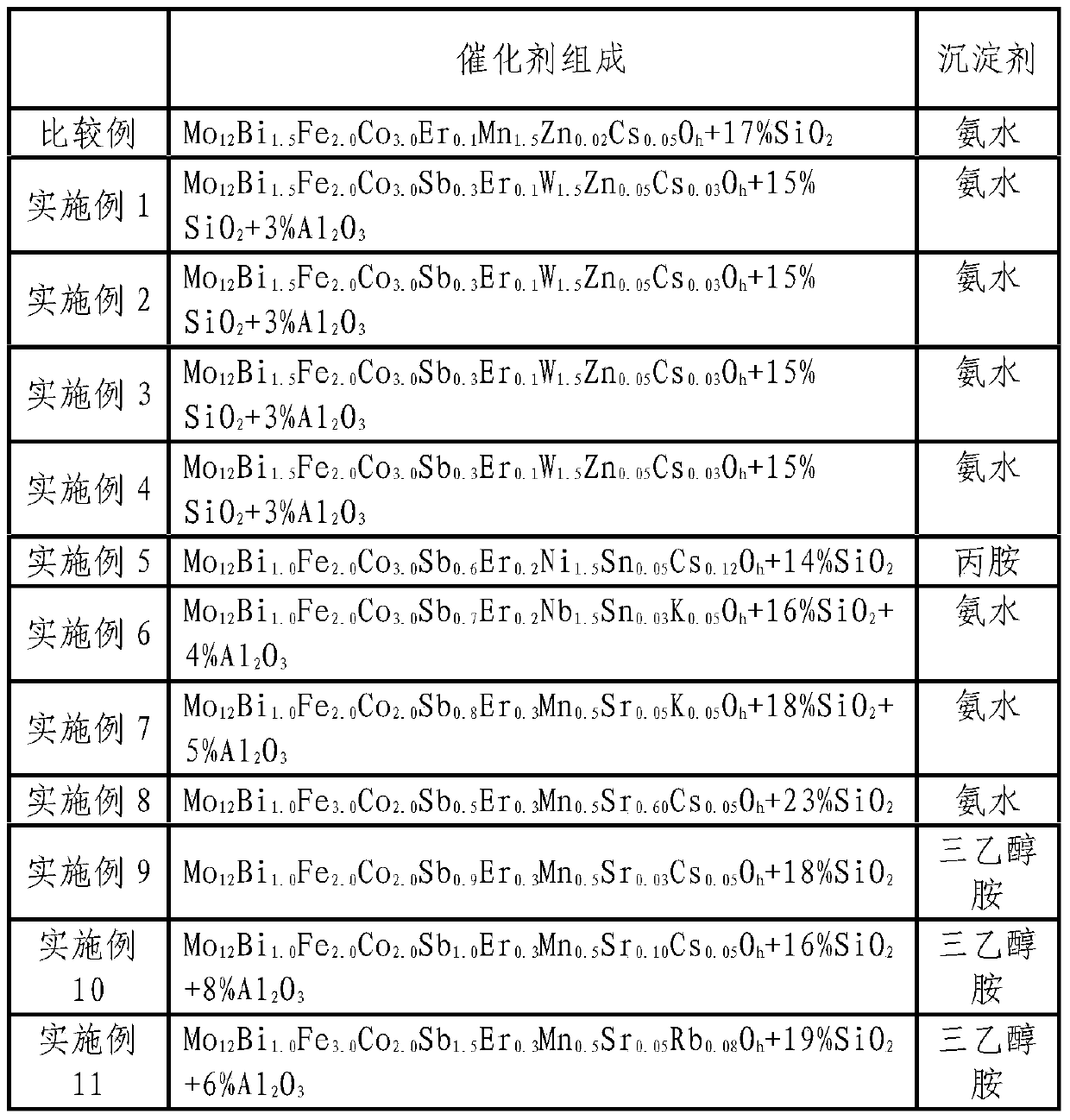

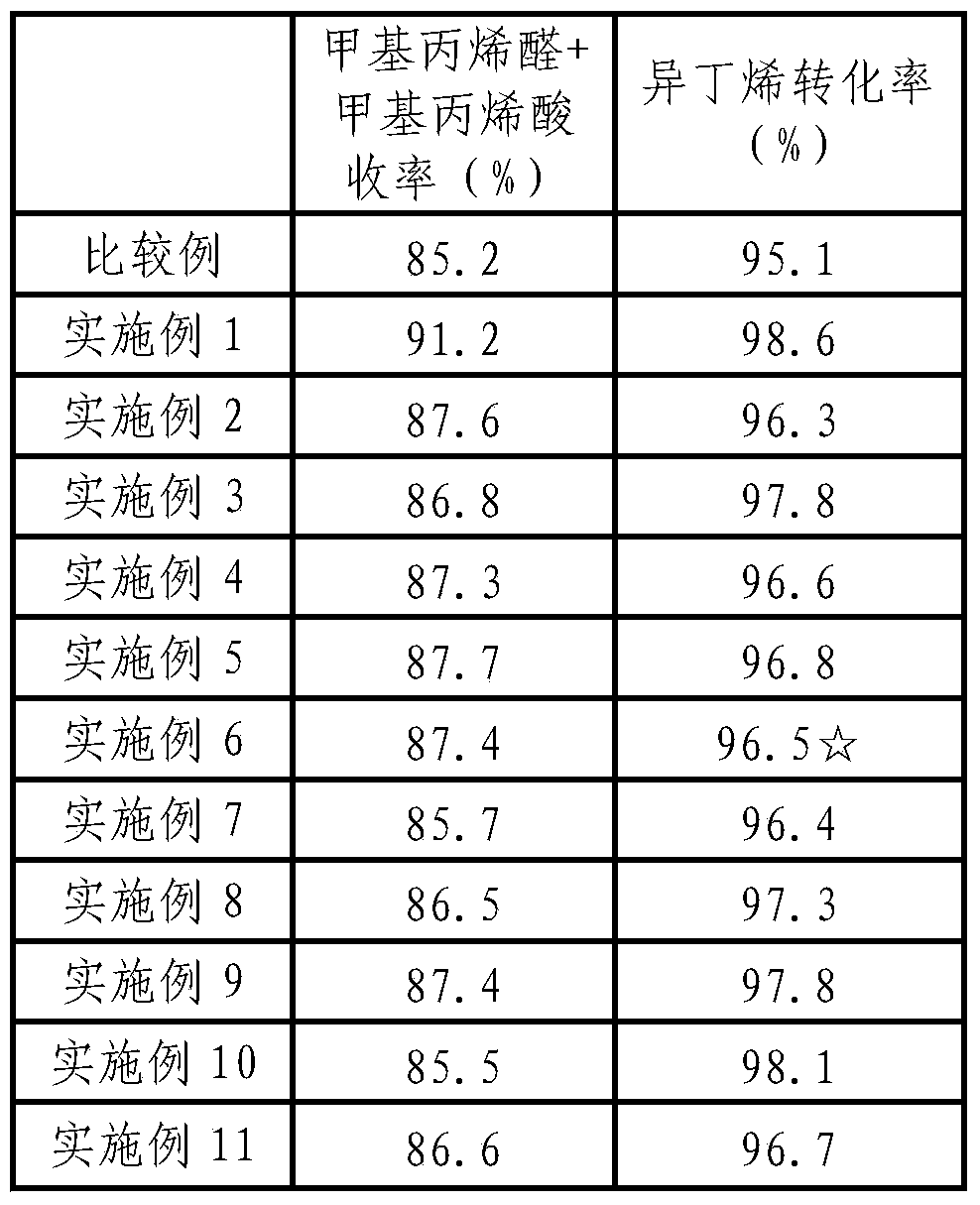

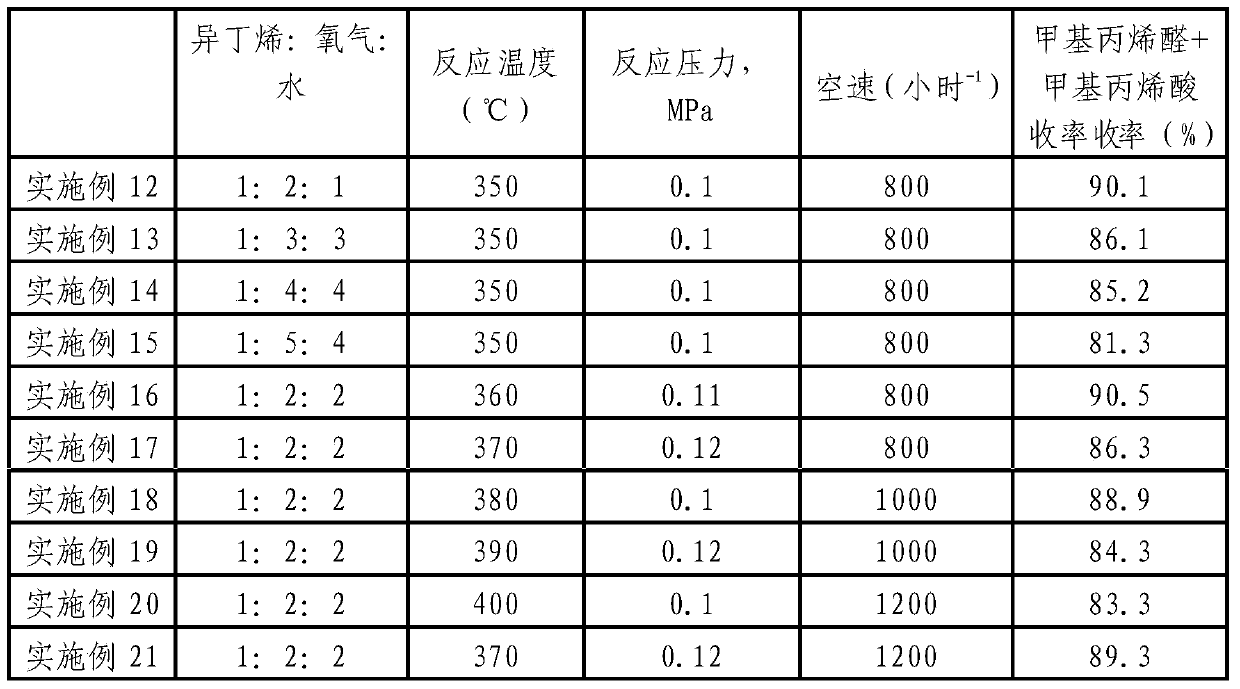

Examples

Embodiment 1

[0043] Catalyst preparation:

[0044] 100 g (NH 4 ) 6 Mo 7 o 24 4H 2 O was added to 100 g of water at 70° C., stirred to dissolve it completely, and 89.4 g of 40 wt % silica sol and 35.8 g of 20 wt % aluminum sol were added to obtain mixture I.

[0045] 38.5 g Fe(NO 3 ) 3 9H 2 O was added to 150 grams of water at 70°C, stirred and dissolved, and then 34.3 grams of Bi(NO 3 ) 3 ·5H 2 O, 41.2 g Co(NO 3 ) 2 ·6H 2 O, 2.1 g Er(NO 3 ) 3 ·3H 2 O, 0.7 g Zn(NO 3 ) 2 ·6H 2 O, 0.27 g CsNO 3 and 19.1 g (NH 4 ) 6 h 5 [H 2 (WO 4 ) 6 ] After stirring and dissolving, solution II was obtained.

[0046] Solution II was added to mixture I with stirring to obtain catalyst slurry III.

[0047] Adjust the pH value of the slurry III to pH 4 with commercially available ammonia water (concentration: 25w%) to obtain slurry IV.

[0048] Slurry IV was dried at 120° C. to obtain catalyst precursor V.

[0049] Mix 0.4 grams of antimony trioxide and the above-mentioned catalyst p...

Embodiment 2

[0053] Catalyst preparation:

[0054] 100 g (NH 4 ) 6 Mo 7 o 24 4H 2 O was added to 100 g of water at 70° C., stirred to dissolve it completely, and 89.4 g of 40 wt % silica sol and 35.8 g of 20 wt % aluminum sol were added to obtain mixture I.

[0055] 38.5 g Fe(NO 3 ) 3 9H 2 O was added to 150 grams of water at 70°C, stirred and dissolved, and then 34.3 grams of Bi(NO 3 ) 3 ·5H 2 O, 41.2 g Co(NO 3 ) 2 ·6H 2 O, 2.1 g Er(NO 3 ) 3 ·3H 2 O, 0.7 g Zn(NO 3 ) 2 ·6H 2 O, 0.27 g CsNO 3 , 19.1 g (NH 4 ) 6 h 5 [H 2 (WO 4 ) 6 ] and 0.4 g of antimony trioxide were stirred and dissolved to obtain solution II.

[0056] Solution II was added to mixture I with stirring to obtain catalyst slurry III.

[0057] Adjust the pH value of the slurry III to pH 4 with commercially available ammonia water (concentration: 25w%) to obtain slurry IV.

[0058] Slurry IV was dried at 120° C. to obtain catalyst precursor V.

[0059] Mix the above catalyst precursor V with water a...

Embodiment 3

[0063] Catalyst preparation:

[0064] 100 g (NH 4 ) 6 Mo 7 o 24 4H 2 O was added to 100 g of water at 70° C., stirred to dissolve it completely, and 89.4 g of 40 wt % silica sol and 35.8 g of 20 wt % aluminum sol were added to obtain mixture I.

[0065] 38.5 g Fe(NO 3 ) 3 9H 2 O was added to 150 grams of water at 70°C, stirred and dissolved, and then 34.3 grams of Bi(NO 3 ) 3 ·5H 2 O, 41.2 g Co(NO 3 ) 2 ·6H 2 O, 2.1 g Er(NO 3 ) 3 ·3H 2 O, 0.7 g Zn(NO 3 ) 2 ·6H 2 O, 0.27 g CsNO 3 and 19.1 g (NH 4 ) 6 h 5 [H 2 (WO 4 ) 6 ] After stirring and dissolving, solution II was obtained.

[0066] Under stirring, solution II was added to mixture I, and 0.4 g of antimony trioxide was added to obtain catalyst slurry III.

[0067] Adjust the pH value of the slurry III to pH 4 with commercially available ammonia water (concentration: 25w%) to obtain slurry IV.

[0068] Slurry IV was dried at 120° C. to obtain catalyst precursor V.

[0069] Mix the above catalyst pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com