Nuclear primary blasting valve shear cap forging process

A technology of blasting valve and process, which is applied in the direction of valve device, etc., can solve the problems that the performance of forgings cannot be guaranteed to meet the blasting valve project, etc., and achieve the effect of mechanical performance, uniform performance, and uniform structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

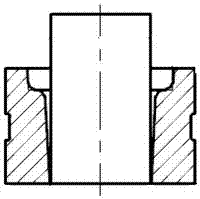

Image

Examples

Embodiment Construction

[0037] The present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

[0038] The forging process of the shear cap of the nuclear primary blasting valve is characterized in that it includes the following specific process steps:

[0039] 1. Raw material cutting

[0040] Carry out blanking according to the required size. After the blanking is completed, it will form a section of the required shape, and the edges and corners of the end of the section will be blunted;

[0041] The obtuse angle R of the end corners is 5%-10% of the diameter of the material section; taking the 18-inch shear cap as an example, the blanking size is Ф380×1158, the end chamfer R30, round steel or square steel.

[0042] 2. Raw material heating

[0043] 1) Heating furnace heating pre-treatment

[0044] Chamber-type heating furnace is adopted, and austenitic stainless steel plates without ferrite should be paved in the furnace before heating....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com