Tubular pile distribution control device, system and method

A technology for controlling equipment and fabric, applied in auxiliary forming equipment, manufacturing tools, supply devices, etc., can solve the problems of poor automatic distribution of pipe piles, low accuracy of distribution control, and low quality of distribution, so as to reduce impact, avoid Interference, the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

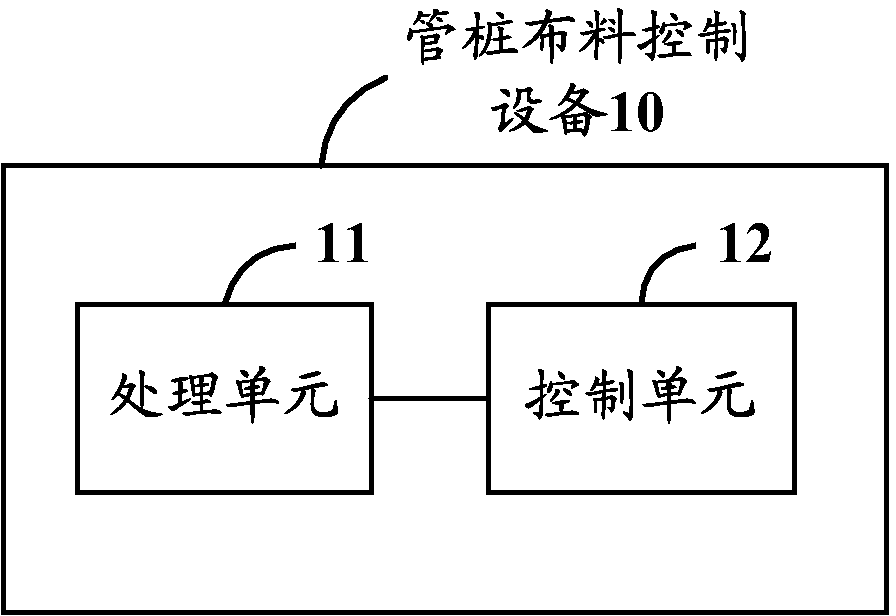

[0027] Embodiment 1 of the present invention provides a pipe pile distribution control device, which can be applied to a pipe pile pumping distribution system including a concrete pumping device, a pipe pile formwork, and a pipe pile formwork transportation device . Such as figure 1 As shown, it is a schematic structural diagram of the pipe pile distribution control device 10 in Embodiment 1 of the present invention. The pipe pile distribution control device 10 may include:

[0028] The processing unit 11 can be used to determine the amount of cloth required per unit length of the pipe pile, and during the cloth distribution process, at the end of each pumping reversing cycle of the concrete pumping device, according to the required amount per unit cloth length The volume of material distribution and the operating displacement of the pipe pile formwork transport device in this pumping reversing cycle determine the target square volume of the pipe pile formwork transporting de...

Embodiment 2

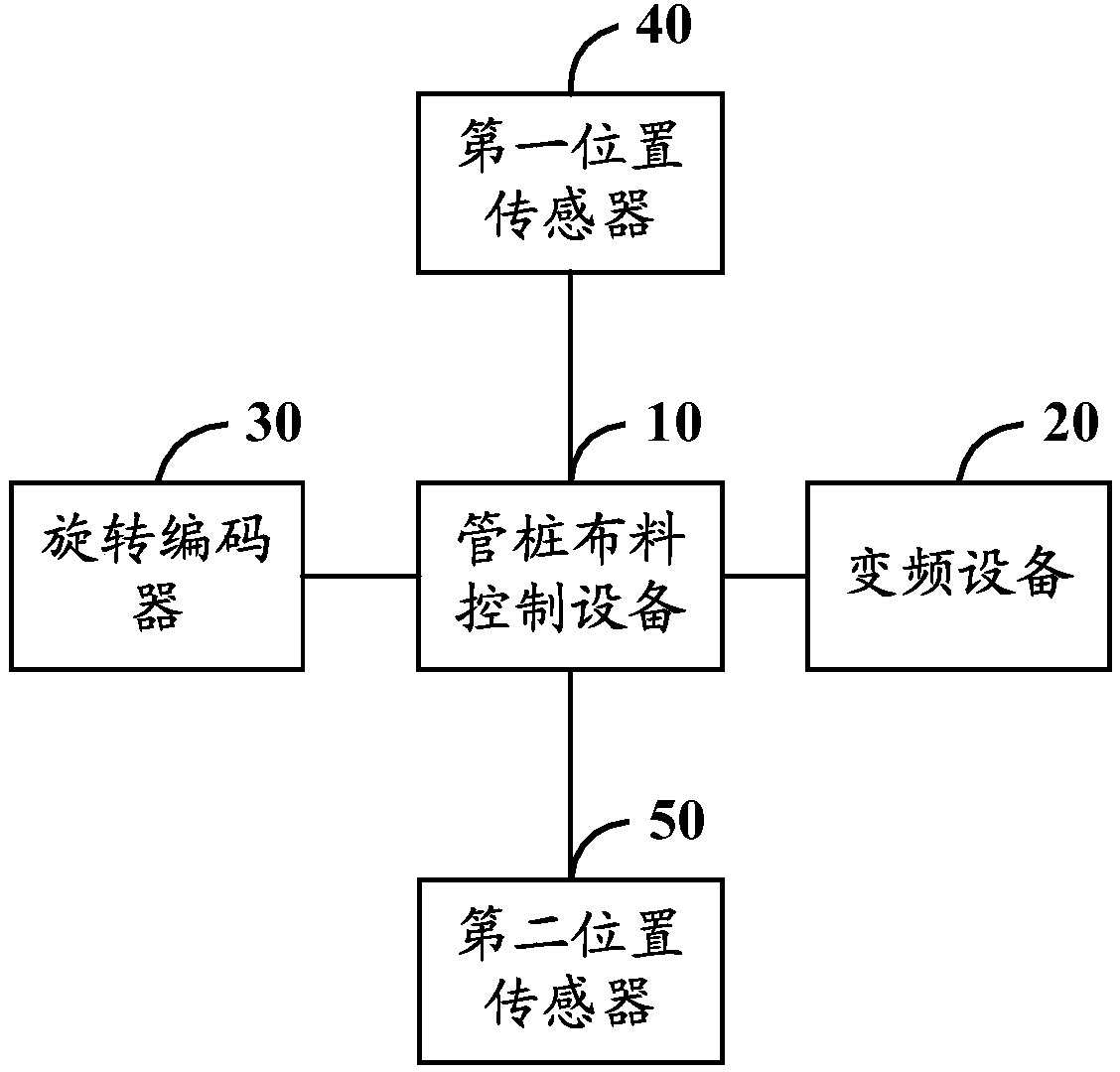

[0052] Embodiment 2 of the present invention provides a pipe pile distribution control system, which can be applied to a pipe pile pumping distribution system including a concrete pumping device, a pipe pile formwork, and a pipe pile formwork transportation device , which will not be described in detail in this embodiment of the present invention.

[0053] Specifically, such as figure 2 As shown, it is a structural schematic diagram of the pipe pile distribution control system described in Embodiment 2 of the present invention. The pipe pile distribution control system may include the pipe pile distribution control device 10 described in Embodiment 1 of the present invention, wherein the For the specific structure and functions of the pipe pile material distribution control device 10, reference may be made to the relevant descriptions in Embodiment 1 of the present invention, and details will not be repeated in Embodiment 2 of the present invention.

[0054] Further, as fi...

Embodiment 3

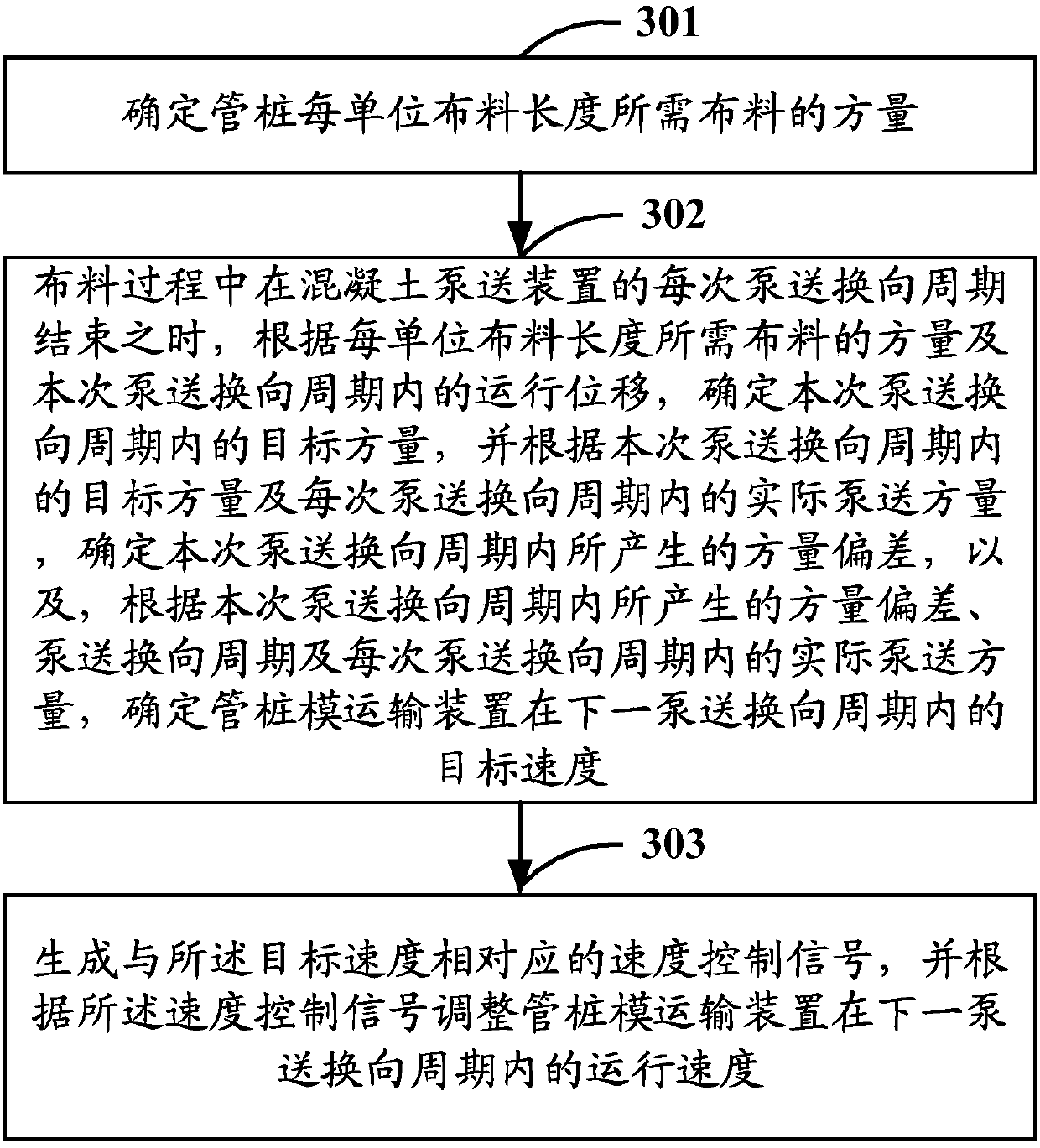

[0066] Embodiment 3 of the present invention provides a pipe pile distribution control method, which can be applied to a pipe pile pumping distribution system including a concrete pumping device, a pipe pile formwork, and a pipe pile formwork transportation device . Such as image 3 As shown, it is a schematic flow chart of the pipe pile distribution control method described in Embodiment 3 of the present invention, and the method may include the following steps:

[0067] Step 301: Determine the amount of fabric required per unit fabric length of the pipe pile.

[0068] Specifically, in the third embodiment of the present invention, the execution subject of each step may generally be the pipe pile distribution control device described in the first or second embodiment of the present invention, which will not be described in detail in the embodiment of the present invention.

[0069] Further, determining the amount of fabric required per unit fabric length of the pipe pile ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com