A metal matrix and its surface treatment method, metal-resin composite and its manufacturing method

A technology of metal matrix and metal resin, applied in the direction of coating, etc., can solve the problems of poor binding force, difficult to remove, not resistant to acid and alkali, etc., and achieve the effect of improving binding force and excellent binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0047] Take a SUS304 stainless steel plate with a thickness of 1mm, cut it into a rectangular piece of 15mm×80mm, put it into a polishing machine for polishing, and then perform degreasing, water washing, sandblasting, water washing, and drying at 80°C in sequence. Obtain a stainless steel substrate.

Embodiment 1

[0049] This example is used to illustrate the surface treatment method of the metal substrate of the present invention, the metal substrate prepared by this method, and the metal-resin composite body and its manufacturing method.

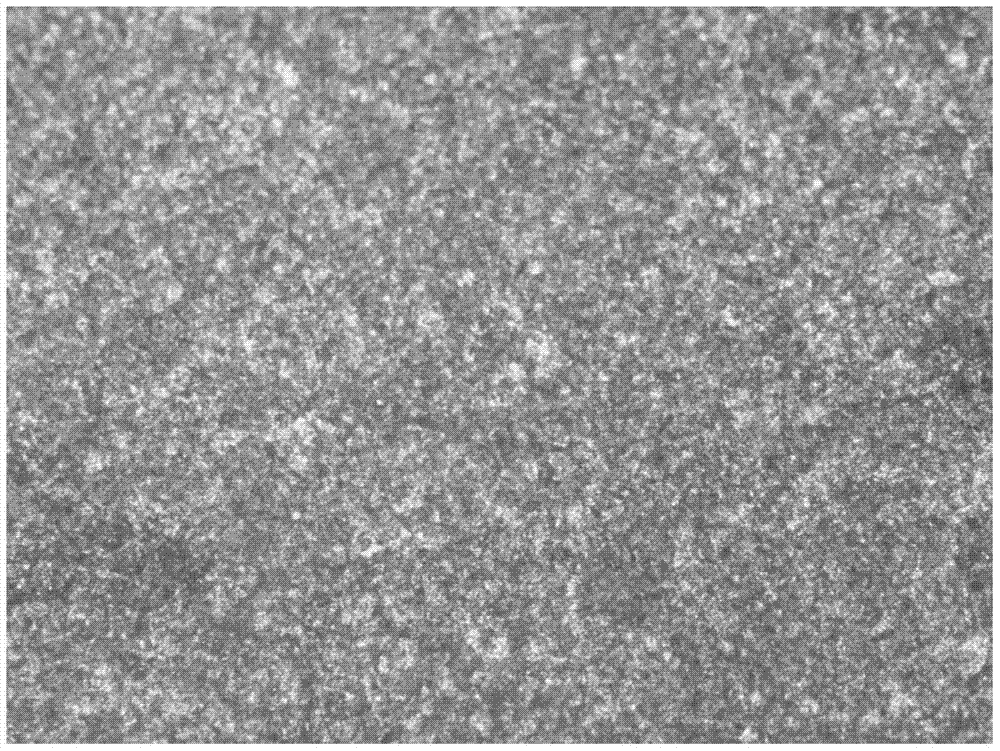

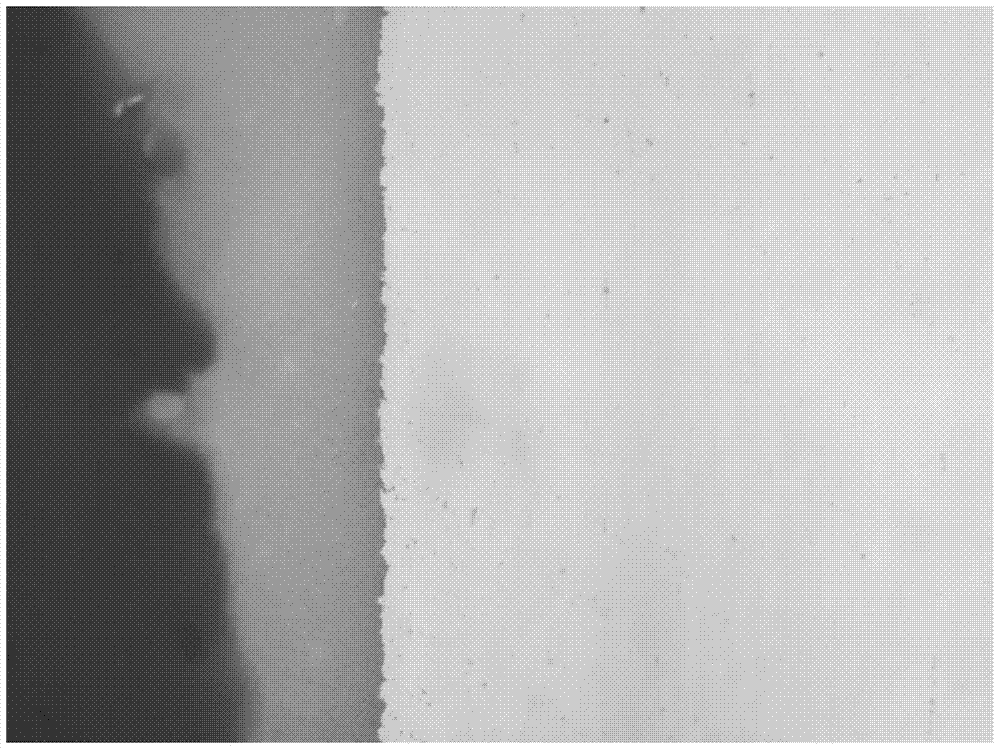

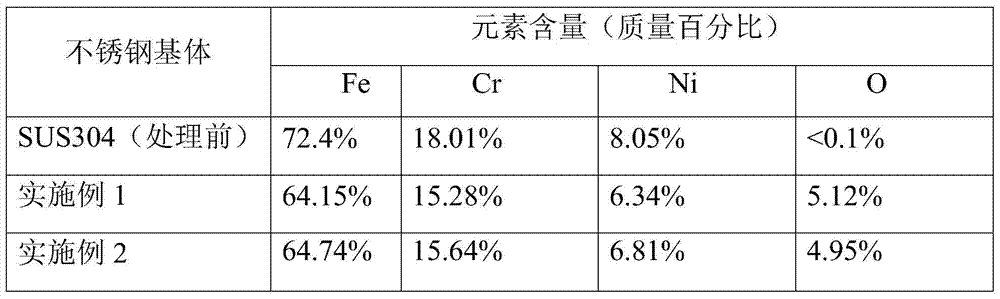

[0050] Put the stainless steel substrate prepared in Preparation Example 1 into a sulfuric acid solution with a weight percentage of 20% by weight, soak it at 40° C. for 120 minutes for pretreatment, and form irregular corrosion holes on the stainless steel substrate; then, take out the stainless steel substrate, Wash with water, then put into 30% by weight of sodium hydroxide solution, use the carbon plate as the cathode, and the stainless steel substrate as the anode, conduct electrochemical corrosion at 3V for 3min, to remove the black on the surface of the pretreated metal substrate Ash layer, take out the stainless steel substrate obtained after electrochemical corrosion and wash and dry to obtain irregular corrosion holes on the surface (the sc...

Embodiment 2

[0055] This example is used to illustrate the surface treatment method of the metal substrate of the present invention, the metal substrate prepared by this method, and the metal-resin composite body and its manufacturing method.

[0056] Put the stainless steel substrate prepared in Preparation Example 1 into a 20% sulfuric acid solution by weight, soak it at 40°C for 120 minutes for pretreatment, and form irregular corrosion holes on the stainless steel substrate; then, take out the stainless steel substrate and wash it with water. , and then soaked in the mixed acid solution for 60 minutes, wherein the mixed acid solution is a mixed acid solution of phosphoric acid and nitric acid, and the concentration of the mixed acid solution is 25% by weight, so as to remove the Take out the stainless steel substrate obtained after chemical immersion and wash and dry to obtain irregular corrosion holes on the surface (the scope of the corrosion holes formed on the metal substrate after ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com