A kind of high wear-resistant transparent coating for metal surface

A technology for transparent coatings and metal surfaces, applied in the direction of alkali metal silicate coatings, antifouling/underwater coatings, coatings, etc., can solve the problem of scratch resistance and poor gloss, low aging resistance, and low wear resistance and other problems, to achieve good protection, high wear resistance, and prevent wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further elaborated below in conjunction with specific examples.

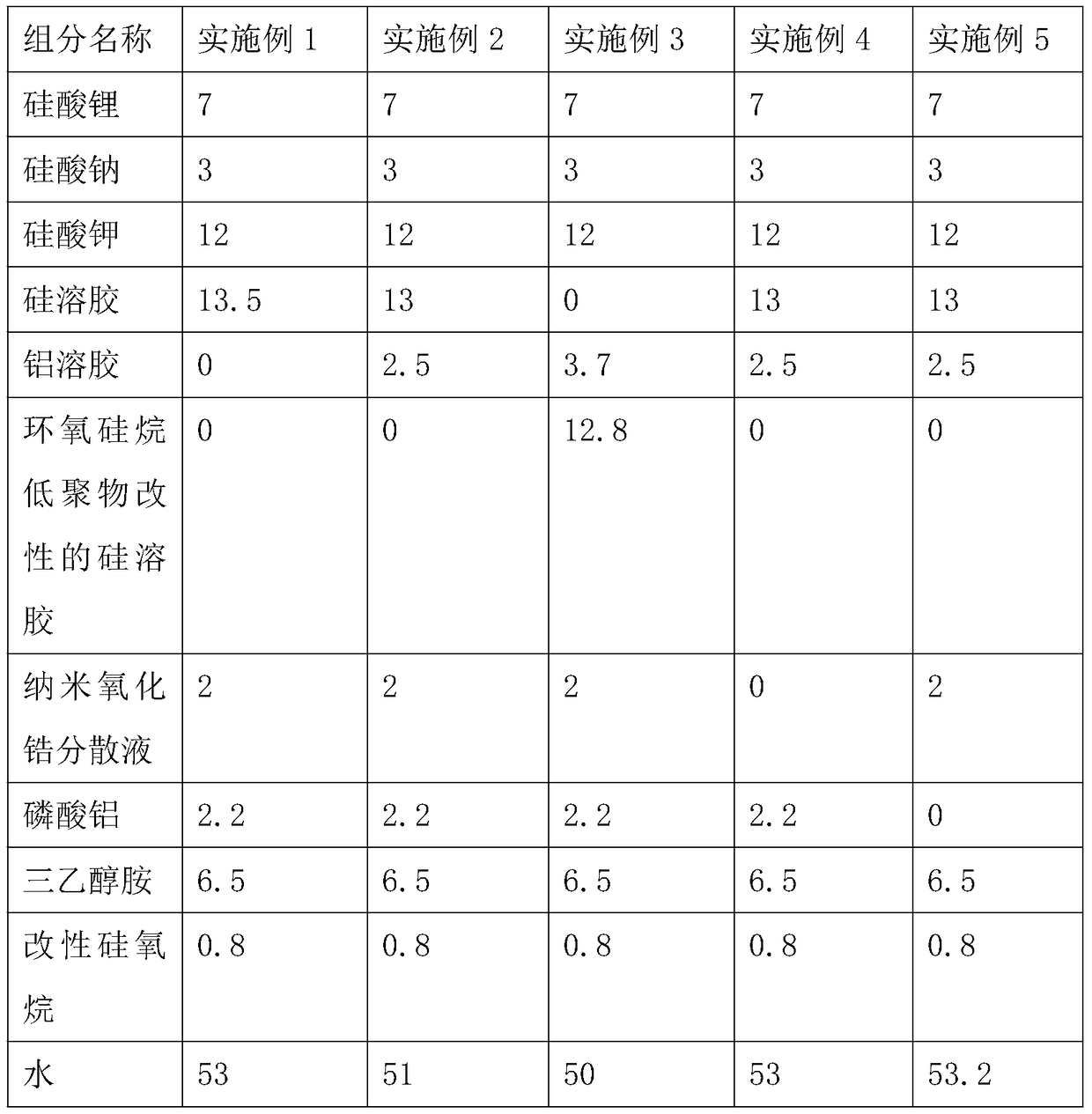

[0025] The high wear-resistant transparent paint that the metal surface of embodiment 1 to embodiment 5 is used, its each component distribution ratio sees Table 1:

[0026] Table 1

[0027]

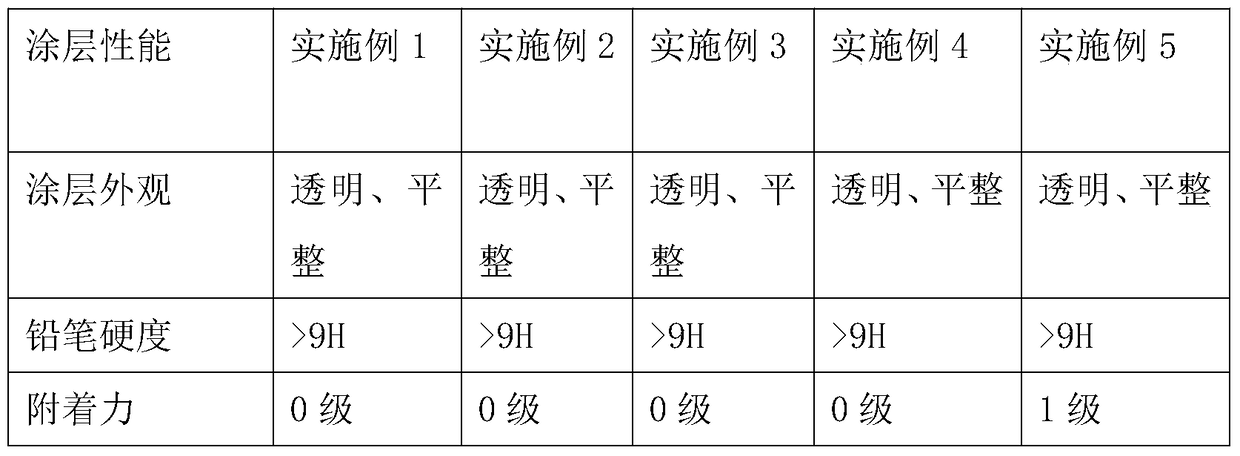

[0028] Prepare coating according to the formula of embodiment 1~embodiment 7 in table 1, adopt spraying mode to make coating on the brushed stainless steel plate of 120mm * 150mm; First bake 10min at low temperature (such as 50 ℃), then at 180 ℃ Bake for 60 minutes; see Table 2 for the detection performance of Examples 1-5.

[0029] Table 2

[0030]

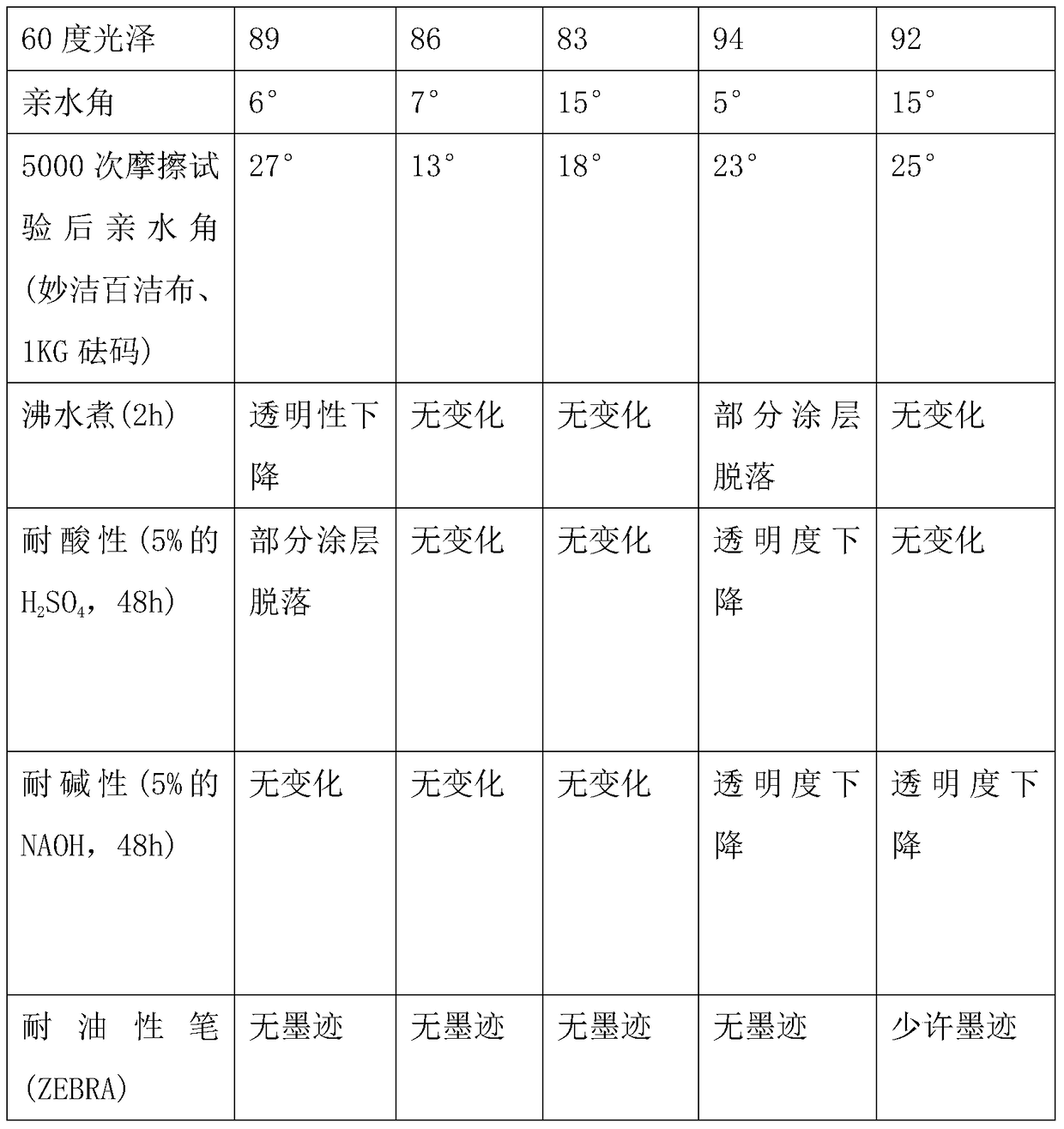

[0031]

[0032] Can get from above-mentioned performance detection result: embodiment 1 to embodiment 3 coating each performance is better, especially adopted the embodiment 3 of epoxy silane oligomer modified silica sol, although its hydrophilic angle is bigger, But its friction resistance is better than other examples, and af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com