Round composite continuous sucker rod operation machine and method

A composite material and sucker rod technology, which is applied in the field of circular composite material continuous sucker rod operation machines, can solve the problems of difficult control of the holding force, easy cracking, and easy pinch breaking, etc., and achieves convenient adjustment and large clamping force. , The effect of convenient clamping pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

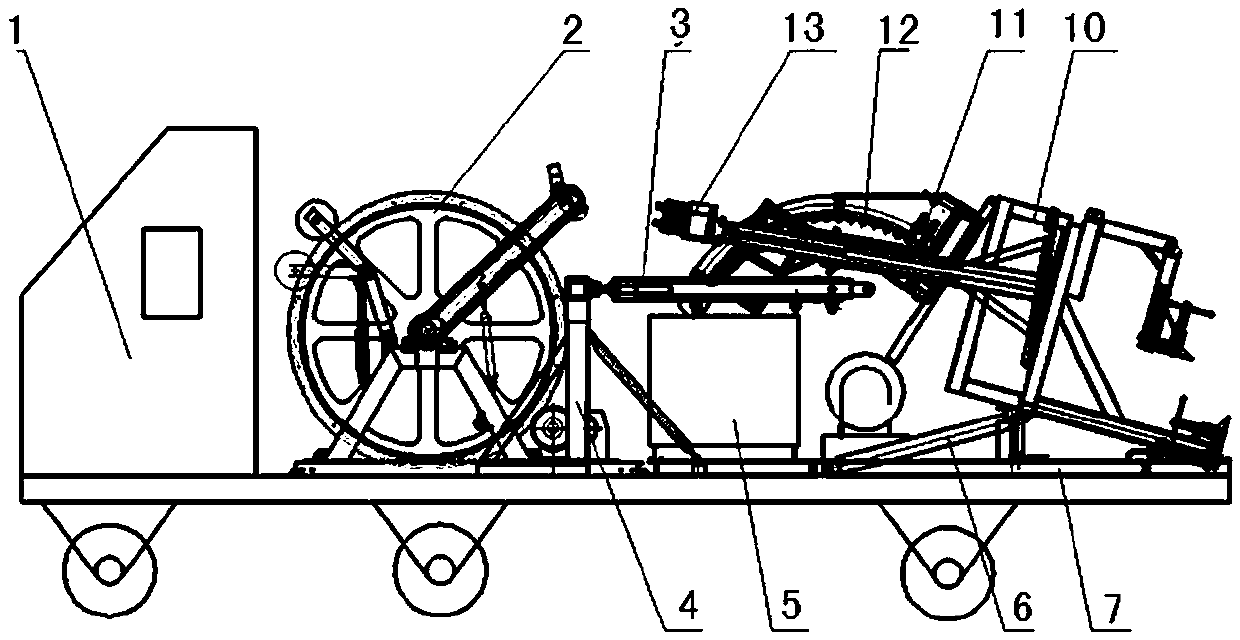

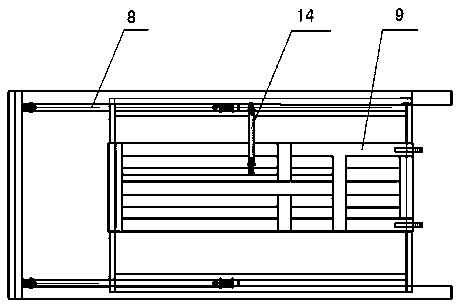

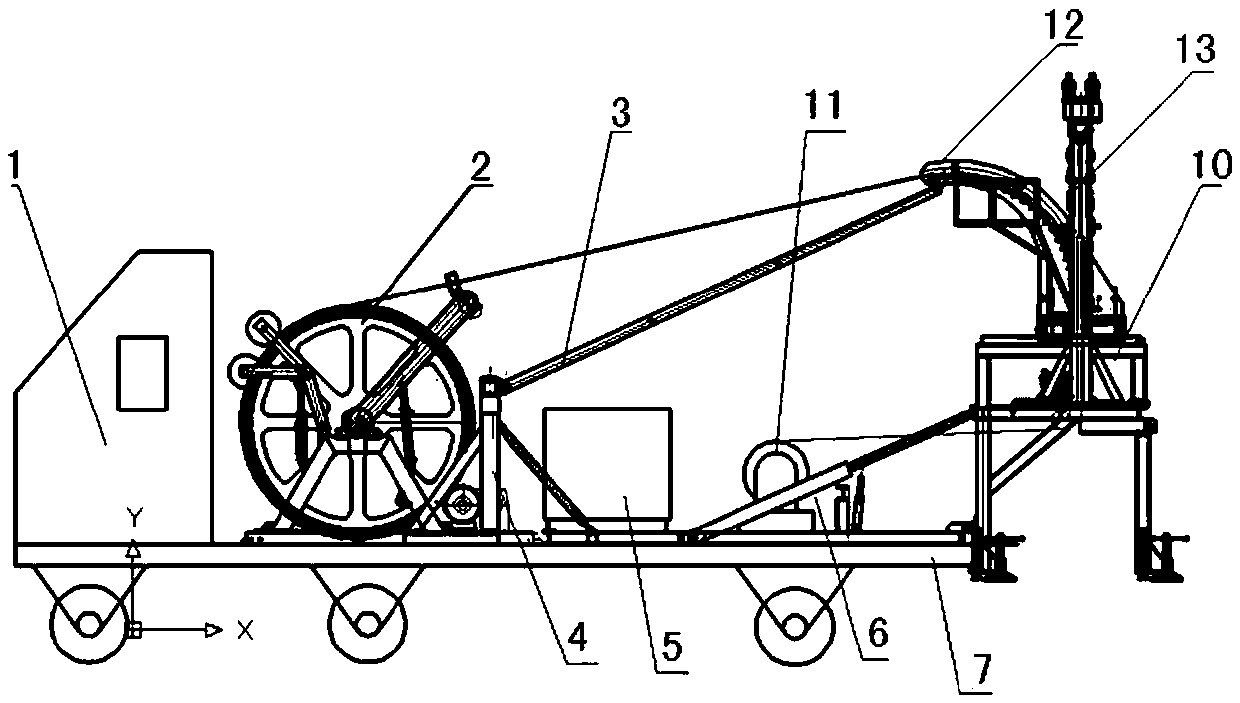

[0031] combined with Figure 1-8 , to further describe the present invention:

[0032]A circular composite material continuous sucker rod operating machine mentioned in the present invention includes a transport vehicle 1, a power drum 2, a strut system 3, a support frame 4, a diesel engine hydraulic station 5, a rotary lifting cylinder 6, and a skid-mounted platform 7 , front and rear telescopic oil cylinders 8, mobile frame 9, wellhead assembly 10, hydraulic winch 11, guide rod frame assembly 12, gantry crane 13, the power drum 2 and skid-mounted platform 7 are fixed on the transport vehicle 1, and the diesel engine The hydraulic station 5 is installed on the skid-mounted platform 7, the support frame 4 and the frame of the power drum 2 are fixed together, one end of the strut system 3 is hinged with the jacket assembly 12, and the other end is hinged with the support frame 4; the hydraulic winch 11 Fixed on the upper part of the mobile frame 9, the cylinder body of the fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com