Input suite of cycloidal reducer and machining method of input suite

The technology of a cycloid reducer and a processing method is applied in the directions of engine components, mechanical equipment, transmission parts, etc., which can solve the problems of short service life, high cost of materials and processing costs, waste of materials, etc., and reduce the cumulative tolerance. , The effect of saving processing time and saving raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

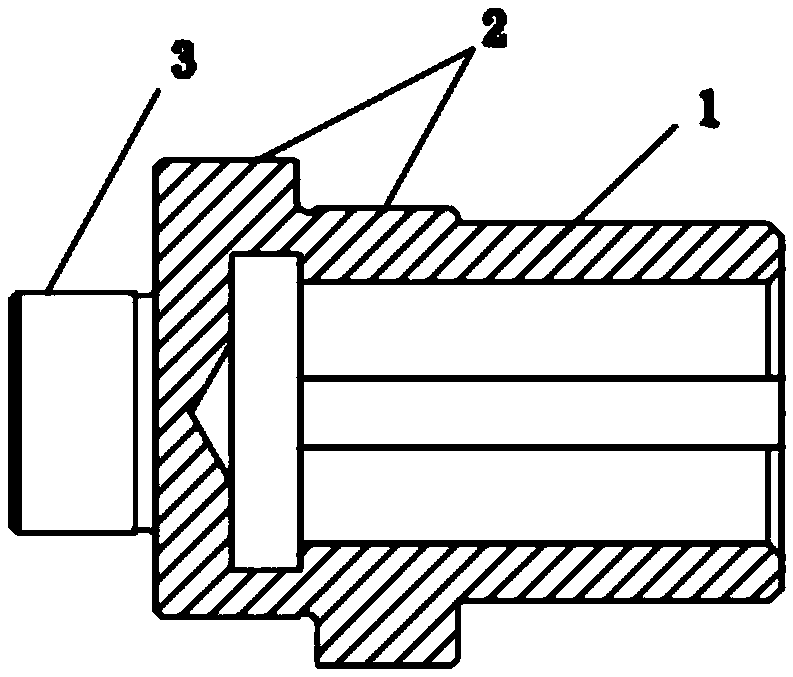

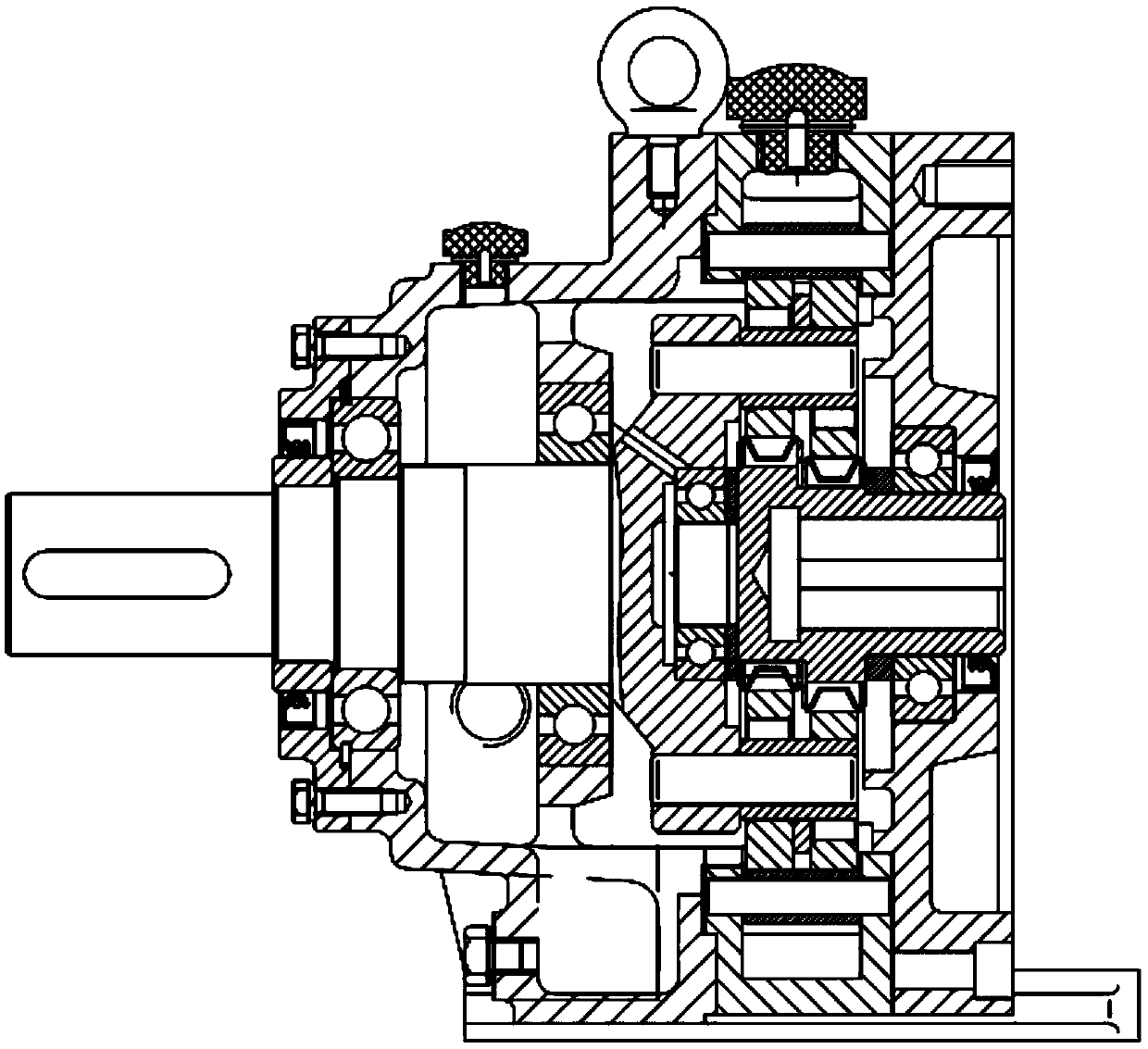

[0029] Such as figure 1 with figure 2 As shown, an input kit of a cycloidal reducer, it is worth noting that it includes an input shaft 1, and an annular protrusion 2 is integrally provided on the periphery of the input shaft, the annular protrusion is circular, and the circumference The facing outer surface is a smooth surface, which is a track for the rolling elements in the bearing to roll, and the center of the ring-shaped protrusion is eccentrically set with the axis center of the input shaft. There are two ring-shaped projections, and the eccentric directions of the two ring-shaped projections are opposite, and the eccentric distances of the two ring-shaped projections are equal. The inside of the input shaft is provided with a plug for the output end of the drive source to be inserted. The hole groove is processed with a keyway on the inner wall of the hole groove. A fixed end 3 for bearing installation is provided protruding from the annular protrusion in the axial ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com