Ammonia injection denitrification system and denitrification process in high temperature flue gas area of large boiler

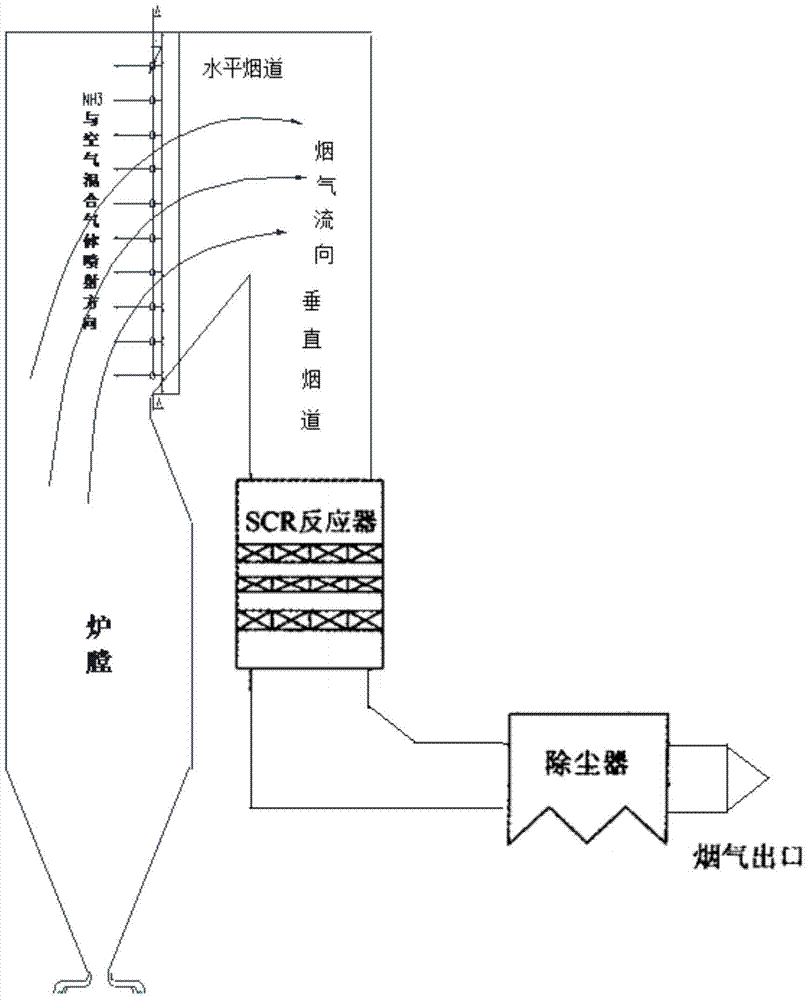

A technology of high-temperature flue gas and regional ammonia injection, applied in gas treatment, combustion product treatment, combustion methods, etc., can solve the problems of poor flue gas purification effect, increased ammonia escape, secondary pollution, etc., and achieve good mixing , Precisely control the reaction conditions and maintain the effect of reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

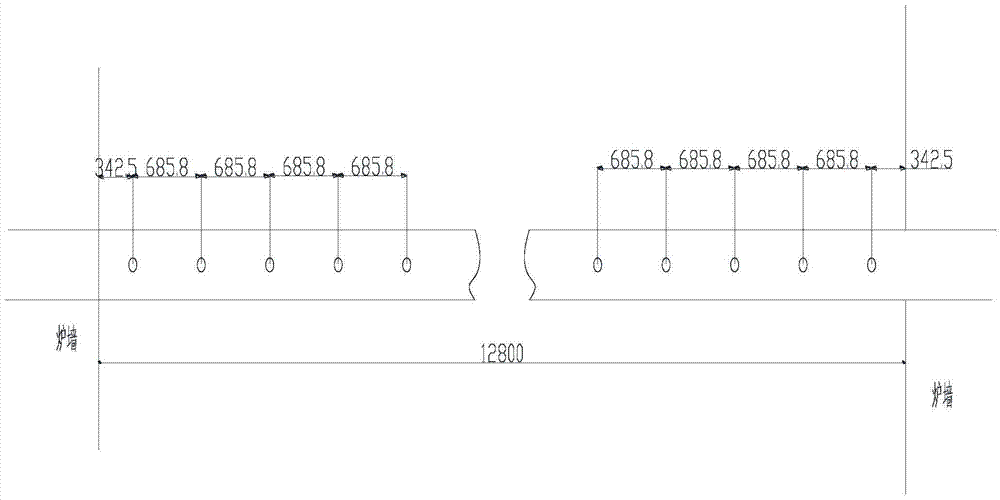

[0054] Embodiment 1: nozzle pipe longitudinal arrangement, the total length of nozzle pipe is 12800mm, offers 19 nozzle holes on this nozzle pipe, and the aperture of nozzle hole is 6-10mm, counts from the nozzle hole of nozzle input end, and aperture changes successively Larger, the pore diameter becomes larger in turn, so that the reducing agent is sprayed more uniformly, and the contact with the flue gas is more uniform, without bias, the purification of the flue gas is more thorough, and at the same time, it can further prevent ammonia from escaping.

[0055] A. Preparation of ammonia gas: ammonia gas is obtained by evaporating liquid ammonia, which is temporarily stored in the reducing agent storage tank;

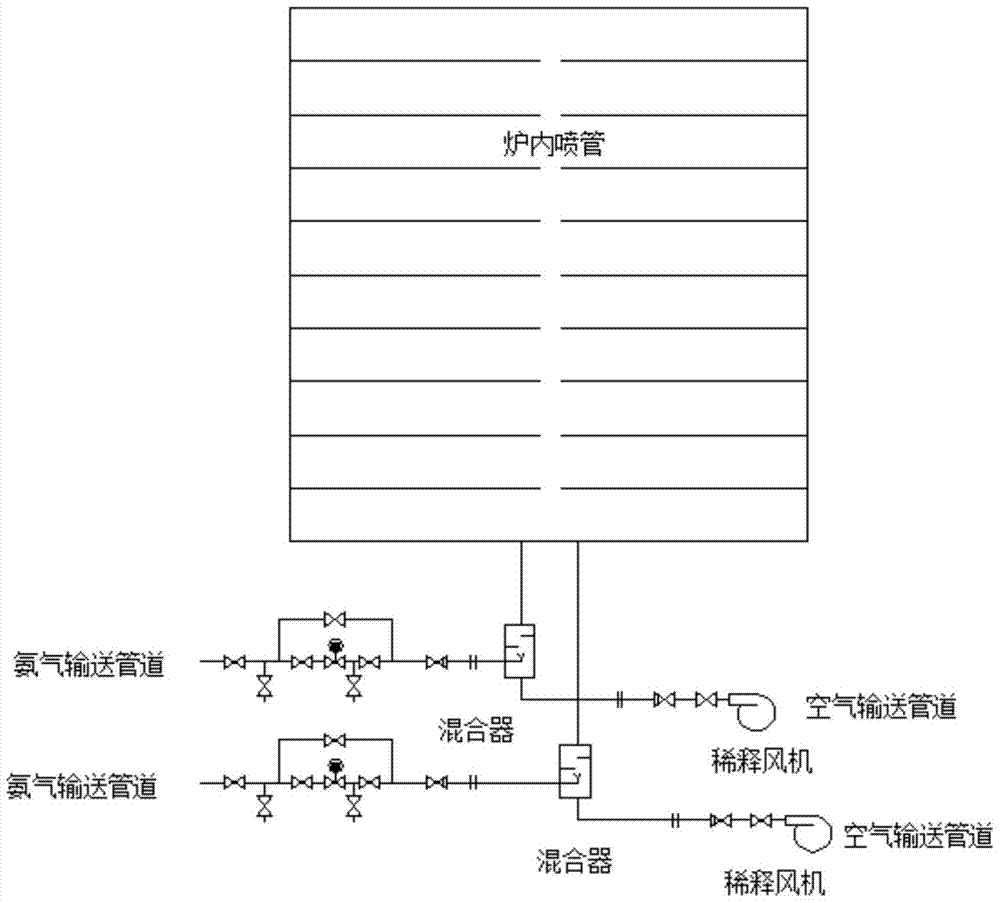

[0056] B. Primary denitrification: the ammonia gas output from the reducing agent storage tank is transported to the mixer through the ammonia gas delivery pipeline, and at the same time, the dilution fan is used to transport the air to the mixer through the air deliver...

Embodiment 2

[0059] Embodiment 2: nozzle pipe is horizontally arranged, and the total length of every nozzle pipe is 6300mm, offers 10 nozzle holes on this nozzle pipe, and the aperture of nozzle hole is 20-30mm, counts from the nozzle hole of nozzle input end, aperture become larger in turn.

[0060] A. Preparation of ammonia gas: ammonia gas is obtained by evaporating liquid ammonia, which is temporarily stored in the reducing agent storage tank;

[0061] B. Primary denitrification: the ammonia gas output from the reducing agent storage tank is transported to the mixer through the ammonia gas delivery pipeline, and at the same time, the dilution fan is used to transport the air to the mixer through the air delivery pipeline, and the ammonia and air are in the mixer After mixing, control the flow of ammonia and air by controlling the valves and flowmeters on the ammonia delivery pipeline and air delivery pipeline, so that the volume ratio of ammonia to air in the mixture is 4%-10%, and th...

Embodiment 3

[0064] Embodiment 3: nozzle pipe longitudinal arrangement, the total length of every nozzle pipe is 13000mm, offers 21 nozzle holes on this nozzle pipe, and the aperture of nozzle hole is 10-15mm, counts from the nozzle hole of nozzle input end, aperture become larger in turn.

[0065] A. Preparation of ammonia gas: ammonia gas is obtained by evaporating liquid ammonia, which is temporarily stored in the reducing agent storage tank;

[0066] B. Primary denitrification: the ammonia gas output from the reducing agent storage tank is transported to the mixer through the ammonia gas delivery pipeline, and at the same time, the dilution fan is used to transport the air to the mixer through the air delivery pipeline, and the ammonia and air are in the mixer After mixing, control the flow of ammonia and air by controlling the valves and flowmeters on the ammonia delivery pipeline and air delivery pipeline, so that the volume ratio of ammonia to air in the mixture is 5%-8%, and then u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com