Lateral smoke discharge and top blowing furnace

A technology of top-blown furnace and smoke outlet, applied in furnace, charge, furnace components, etc., can solve the problems of large consumption of refractory material, high supporting workshop, unstable operation, etc., to prevent the leakage of cooling water, convenient manufacturing, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

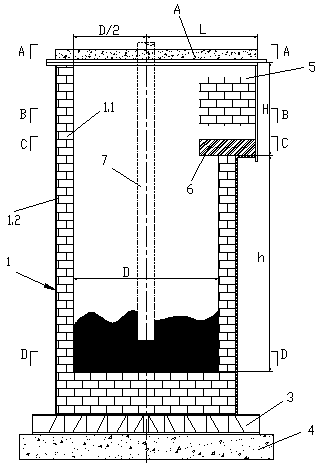

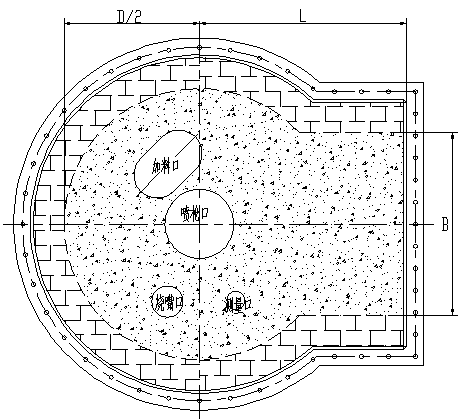

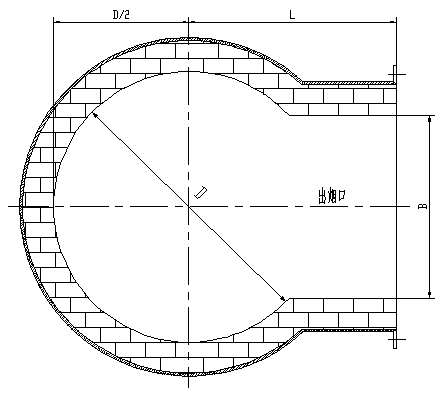

[0017] Embodiment 1: side-type smoke outlet top-blown furnace, including cylindrical vertical furnace body 1, furnace roof cover 2 at the top of furnace body 1, on the furnace roof cover 2, there are spray gun mouth, charging port, heat preservation burner mouth and measurement The furnace body 1 is composed of a refractory brick lining 1.1 and a steel furnace shell 1.2 on the outer surface. Water cooling facilities (such as surface water spray cooling or water jacket cooling) can be installed outside the steel furnace shell 1.2, or no cooling facilities can be provided. Insulation bricks are arranged in the steel furnace shell. A furnace frame 3 is arranged at the bottom end of the furnace body 1 , and the furnace frame 3 is welded to the furnace body 1 . Bolt connection holes are arranged on the furnace frame 3, and the furnace frame 3 is connected with the furnace body foundation 4 through connecting bolts. The strength of the frame 3 is required to be able to withstand th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com