Emulsion explosive medium-length-hole quick-blasting construction method used in coal mine high-temperature fire area

An emulsion explosive and construction method technology, applied in the field of blasting, can solve the problems such as the inability to reach a temperature area that can be reduced to safe construction, inconvenient construction, poor economic benefits, etc., and achieves reduction of economic costs and operation difficulty, safe and fast construction, and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

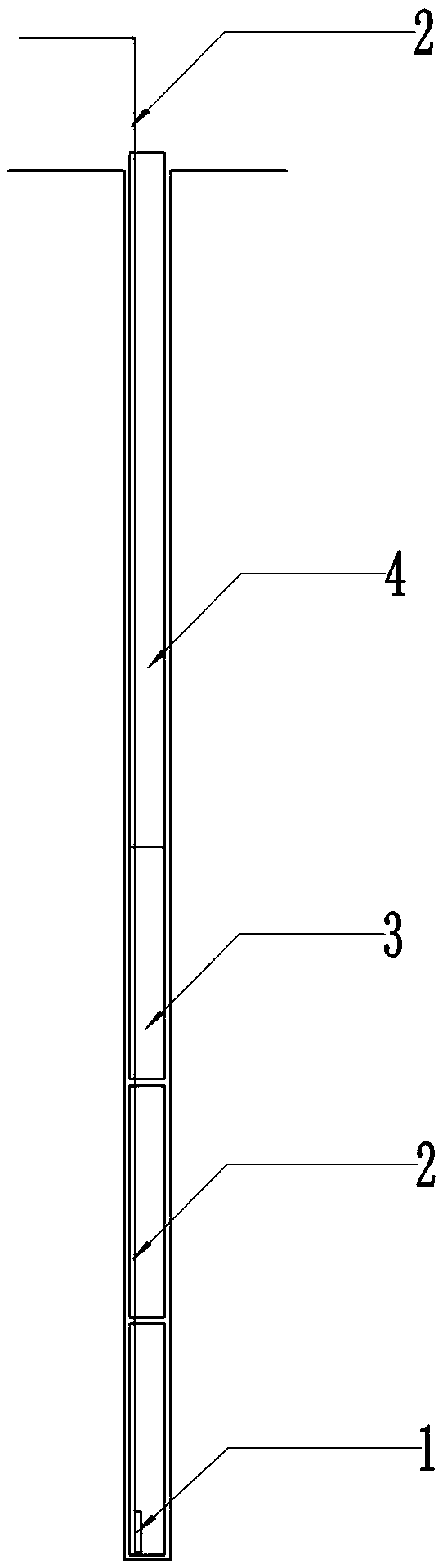

[0021] Such as figure 1 As shown, the construction method of rapid blasting of deep holes in emulsion explosives in high-temperature fire areas of coal mines includes the following steps:

[0022] ① Determine the blasting point and the number of blasting holes in the high-temperature fire area of the coal mine. In this embodiment, the number of blasting holes is 7, and the blasting holes are excavated. The blasting holes are used as the first-order blasting holes, and the depth of the first-order blasting holes is 5m;

[0023] ②A detonating cord 2 is set corresponding to each blasting hole, and one end of each detonating cord 2 is connected to the detonating object 1. One end of the detonating cord, the other end of the leading detonating cord is connected to the detonator;

[0024] ③Each blast hole corresponds to a worker, and each worker first fills in the blasting material 1 at the bottom of the respective blast hole, and then fills two explosive columns 2 into the blast...

Embodiment 2

[0029] Such as figure 1 As shown, the construction method of rapid blasting of deep holes in emulsion explosives in high-temperature fire areas of coal mines includes the following steps:

[0030] ① Determine the blasting point and the number of blasting holes in the high-temperature fire area of the coal mine. In this embodiment, the number of blasting holes is 8, and the blasting holes are excavated. The blasting holes are used as the first-order blasting holes, and the depth of the first-order blasting holes is 8m;

[0031] ②A detonating cord 2 is set corresponding to each blasting hole, and one end of each detonating cord 2 is connected to the detonating object 1. One end of the leading detonating cord, the other end of the leading detonating cord is connected to the detonator;

[0032] ③Each blast hole corresponds to a worker, and each worker first fills initiating materials 1 into the bottom of their respective blast holes, and then fills two explosive columns 2 into ...

Embodiment 3

[0037] Such as figure 1 Shown, a kind of coal mine high temperature fire area emulsion explosive medium deep hole rapid blasting construction method, comprises the following steps:

[0038] ① Determine the blasting point and the number of blasting holes in the high-temperature fire area of the coal mine. In this embodiment, the number of blasting holes is 8, and the blasting holes are excavated. The blasting holes are used as the first-order blasting holes, and the depth of the first-order blasting holes is 6m;

[0039] ②A detonating cord 2 is set corresponding to each blasting hole, and one end of each detonating cord 2 is connected to the detonating object 1. One end of the leading detonating cord, the other end of the leading detonating cord is connected to the detonator;

[0040] ③Each blast hole corresponds to a worker, and each worker first fills in the blasting material 1 at the bottom of the respective blast hole, and then fills two explosive columns 2 into the blas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com