System and method for testing failure of thermal barrier coating

A test system, thermal barrier coating technology, applied in joint test system, thermal barrier coating failure test system, in-situ dynamic non-destructive real-time online monitoring field, can solve the difficulty of acoustic emission signal analysis, distortion, acoustic emission signal attenuation and other issues to achieve the effect of saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described below in conjunction with the drawings and the following embodiments. It should be understood that the drawings and the following embodiments are only used to illustrate the present invention rather than limit the present invention.

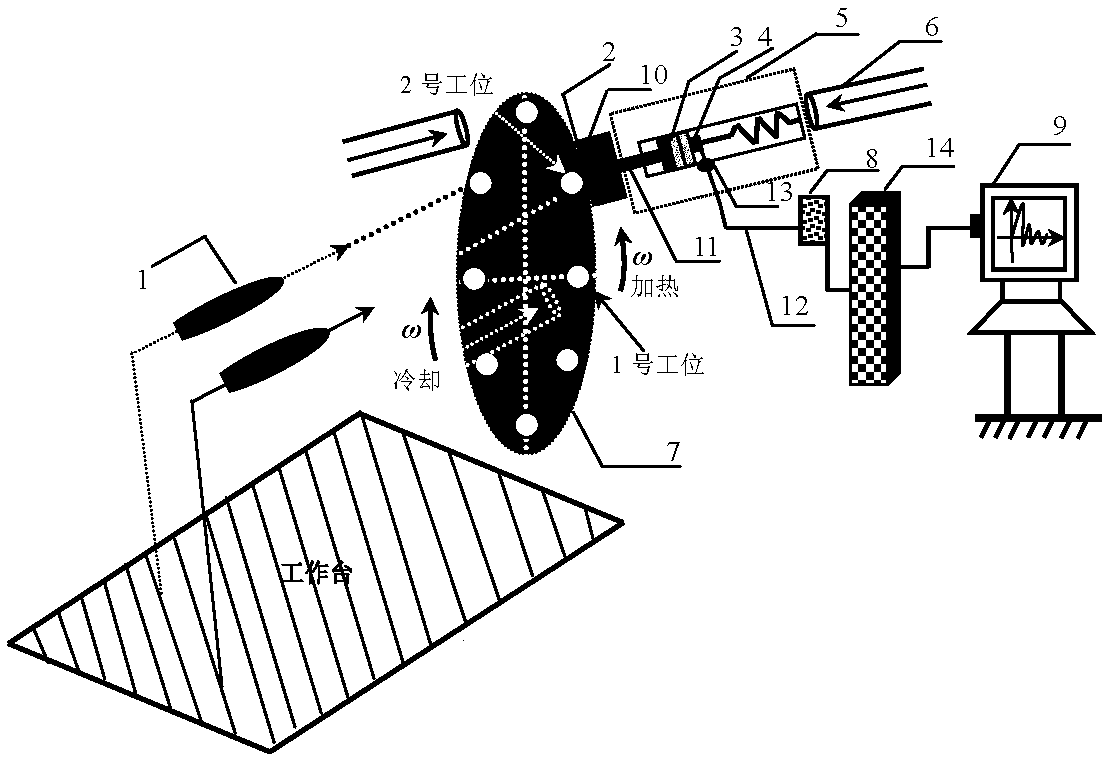

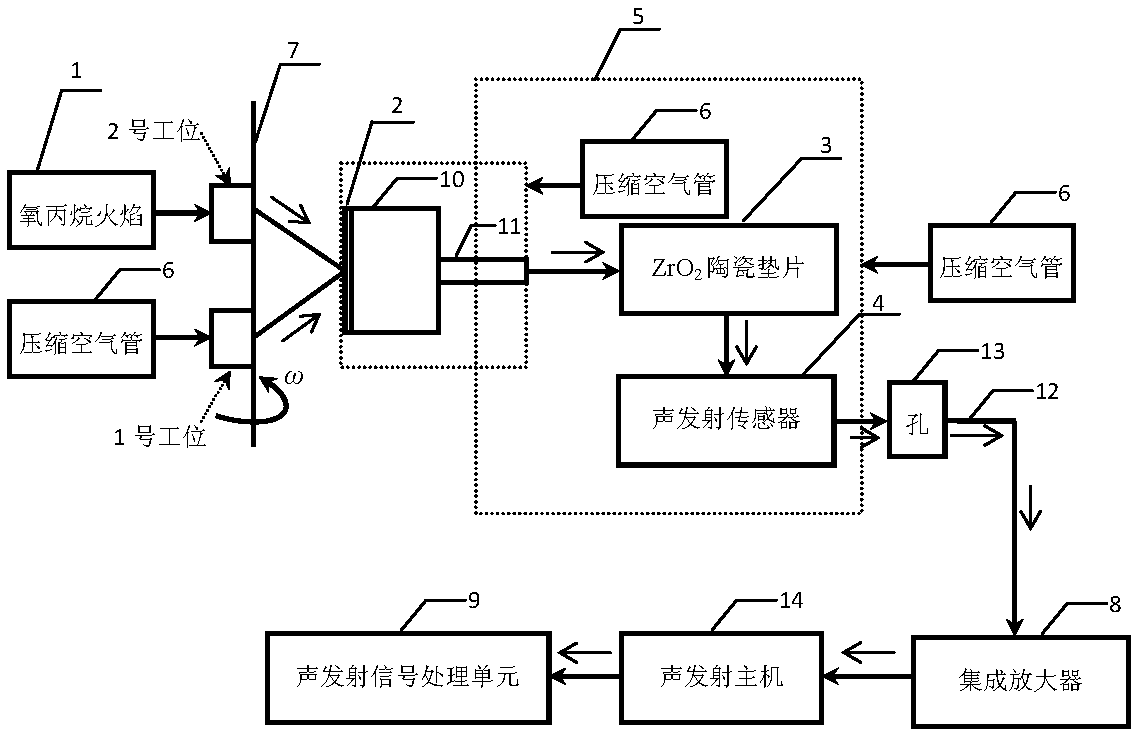

[0052] One of the purposes of the present invention is to solve the prediction of coating failure under high temperature conditions, especially under high temperature and strong heat flux assessment conditions, and then integrate and introduce an acoustic emission signal detection device on the high temperature and strong heat flux cycle thermal assessment device .

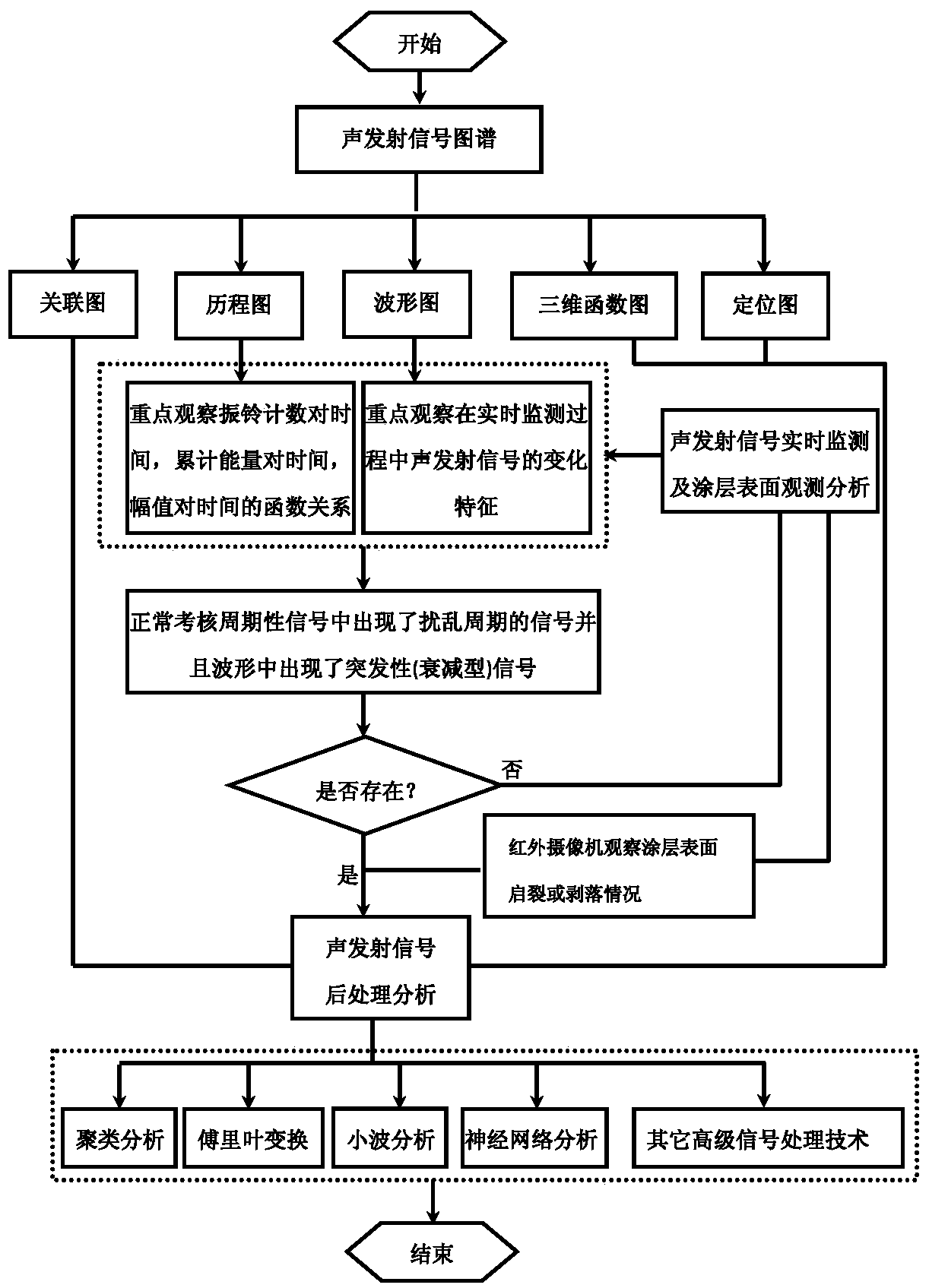

[0053] The second purpose of the present invention is to study the internal mechanism of coating peeling failure under the condition that there is a temperature gradient between the surface and the back of the coating. By analyzing the collected acoustic emission signals, the source information and information of the coating failu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com