Optimal charging method for lithium-ion power battery

A lithium-ion battery, power battery technology, applied in the direction of secondary battery charging/discharging, batteries, electrochemical generators, etc., can solve the problems of long charging time, increase charging current, battery temperature rise too fast, etc. The effect of charging efficiency, reducing impact, and increasing charging speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below in conjunction with specific embodiment the present invention is described in further detail:

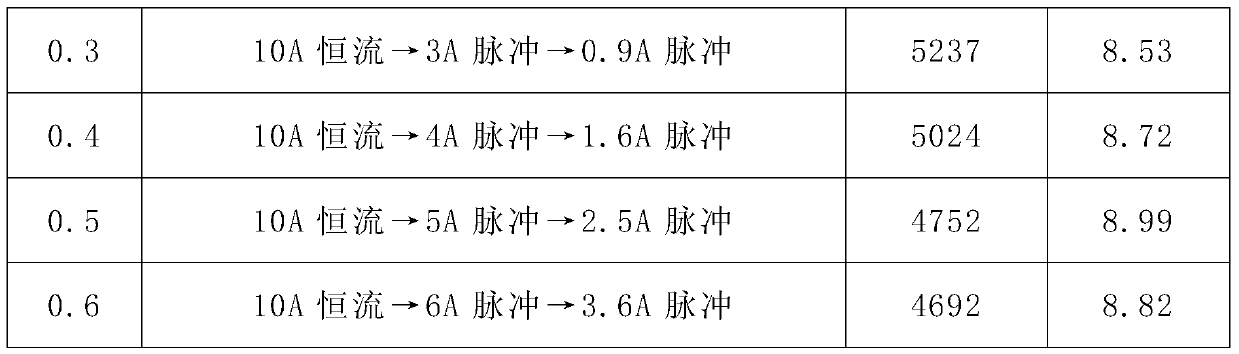

[0011] The optimal charging strategy of this charging method is: at the initial stage of charging, a relatively large charging current should be applied to the lithium-ion battery (the current should not be too large or too small at the initial stage of charging), so that it can charge a large amount of battery in a short period of time at the initial stage of charging. In addition, it is necessary to ensure that the charging current gradually decreases as the charging process proceeds, and at the same time, evaluate the polarization status of the lithium-ion battery and take depolarization measures in due course. , and depolarization measures should accompany the entire charging process.

[0012] The technical scheme adopted in the present invention specifically comprises the following steps:

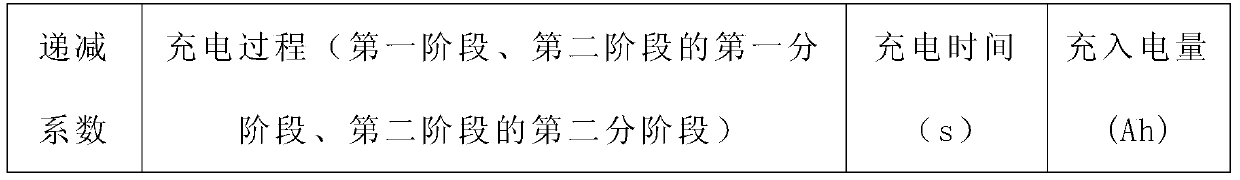

[0013] Step 1: Use various currents to conduct constant current charging e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com