Two-stage series gap lightning flashover protector capable of being replaced in electrified mode

A series gap, live replacement technology, applied in overvoltage protection resistors, overvoltage arresters using spark gaps, circuits, etc. Achieve the effect of reducing power failure detection and replacing lightning protection devices, preventing flashover accidents and extending service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

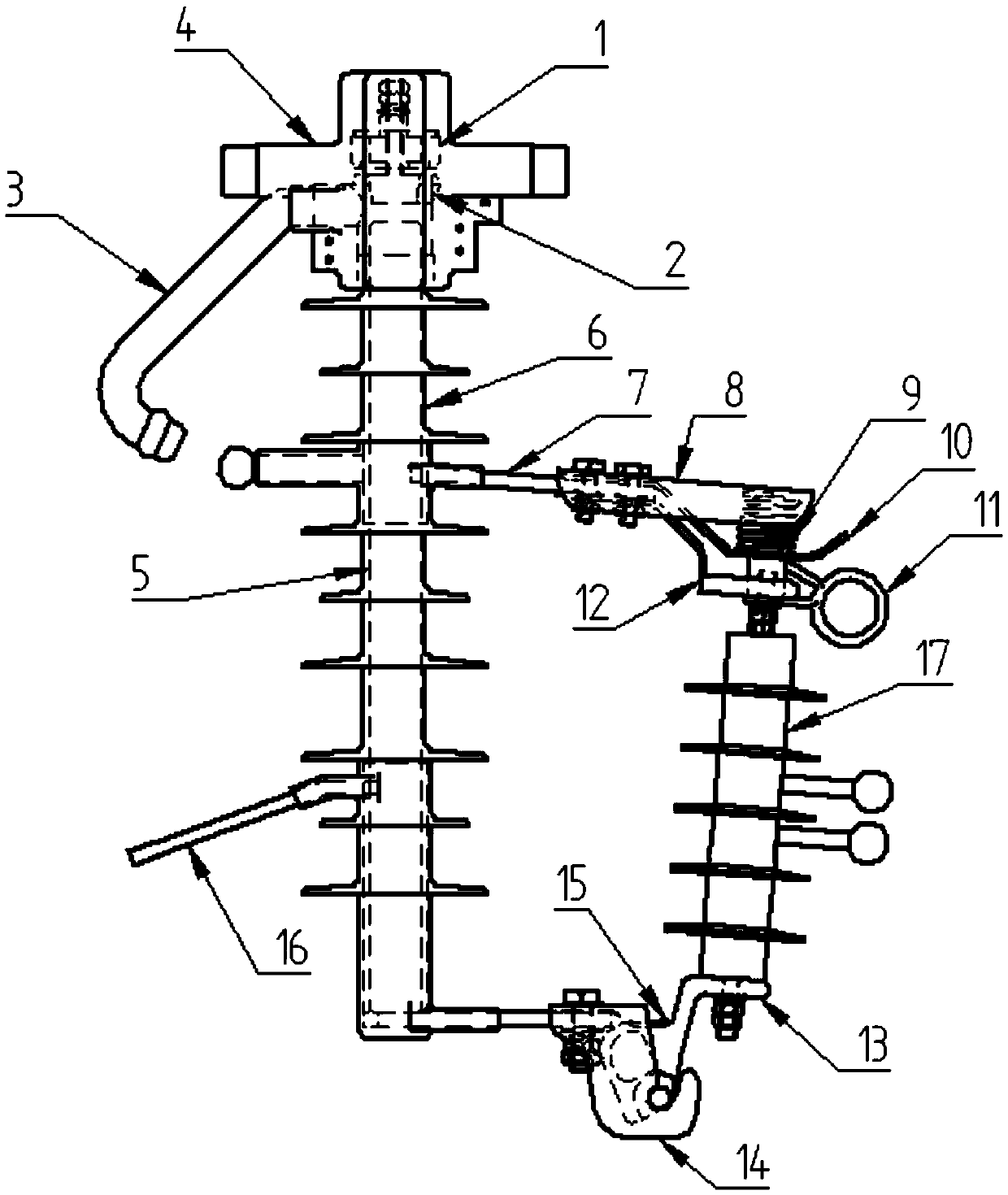

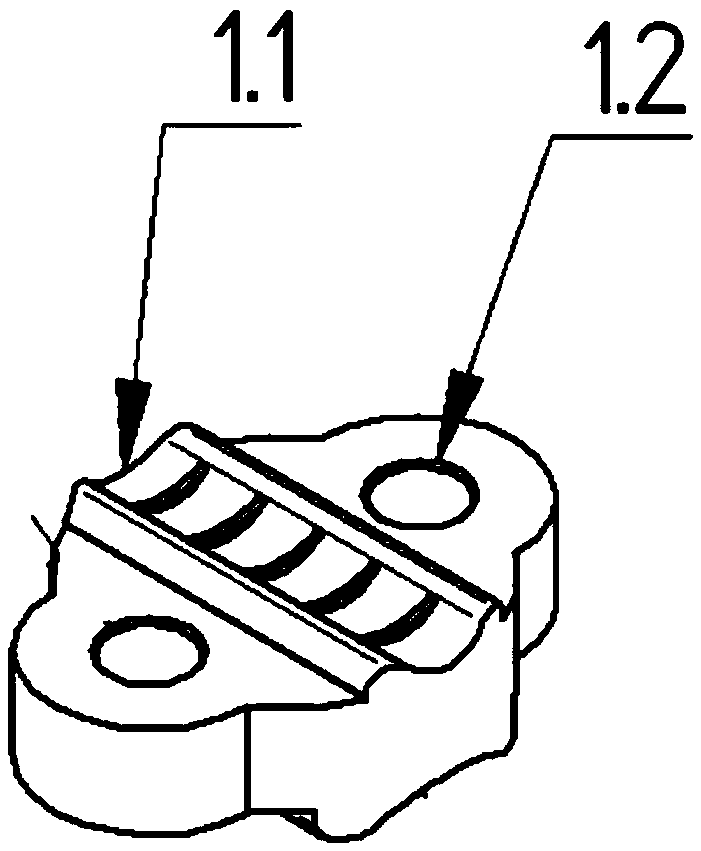

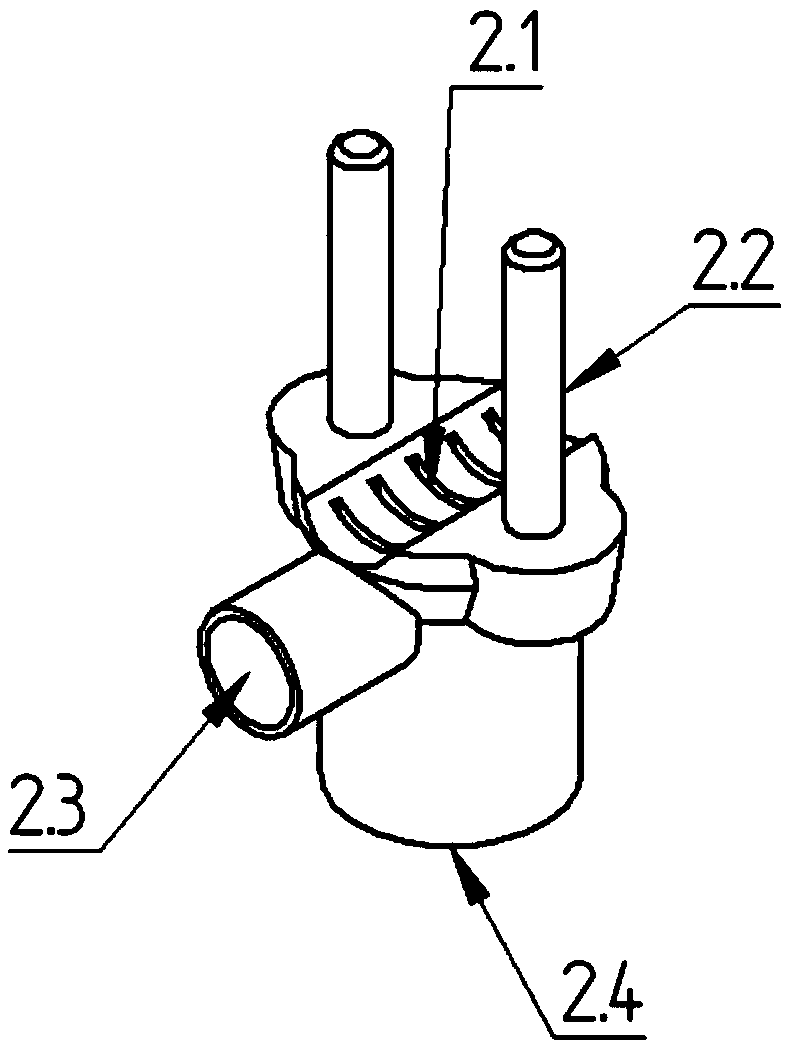

[0046] Such as figure 1 Shown is a live-replaceable two-stage series gap lightning strike flashover protector designed by the present invention, including a wire clamp pressing block 1, a wire clamp seat 2, a drainage rod 3, an insulating sheath assembly 4, a mandrel 5, and a composite jacket 6. Discharge ball fixing component 7, groove-shaped pressing plate 8, spring 9, spring pressing piece 10, pull ring 11, guide piece 12, fixing seat 13, connecting component 14, shrapnel 15, fixed supporting component 16 and zinc oxide arrester 17, Wherein: the surfaces of the discharge ball fixing component 7 and the fixing support component 16 are all treated by hot-dip galvanizing.

[0047] Zinc oxide surge arrester 17 is used to prevent lightning overvoltage and cut-off Zinc oxide surge arrester with external series gap for power frequency f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com