A spindle sealing system for working motors under high temperature or high pressure environment

A high-voltage environment, working motor technology, applied in the direction of engine sealing, electromechanical devices, electrical components, etc., can solve the problems of motor thin oil leakage, motor damage, and easy damage of seals, so as to prevent thin oil leakage and prolong maintenance cycle , Improve the effect of sealing reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

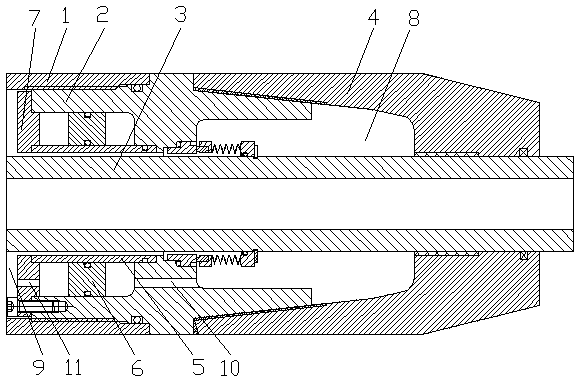

[0041] see figure 1 , a spindle sealing system for motors working in high temperature or high pressure environments, including a first joint 2 connected to the motor housing 1 and a second joint 4 connected to the main shaft 3, the first joint 2 and the second joint 4 are threaded connected, the main shaft 3 is covered with a piston rod 5, the piston rod 5 is connected with a piston 6, one end of the first joint 2 is connected with a piston end cover 7, and the other end is connected with a first seal, and the second joint 4 passes through The second seal is connected with the main shaft 3, the first joint 2, the second joint 4 and the main shaft 3 enclose a transition chamber 8, the motor housing 1, the main shaft 3 and the piston end cover 7 enclose an inner chamber 9, and the first joint 2 A first pressure balance hole 10 is opened on it, and a second pressure balance hole 11 is opened on the piston end cover 7 .

[0042] This embodiment is the most basic implementation. A...

Embodiment 2

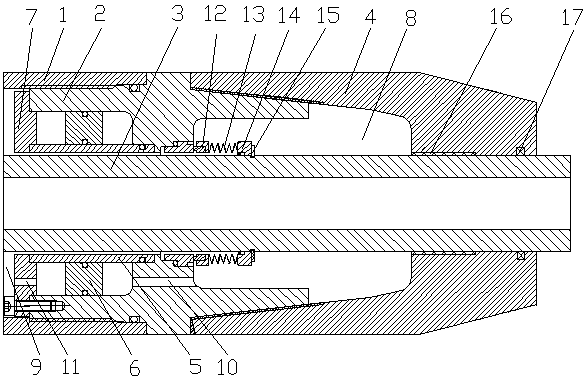

[0044] see figure 2 , a spindle sealing system for motors working in high temperature or high pressure environments, including a first joint 2 connected to the motor housing 1 and a second joint 4 connected to the main shaft 3, the first joint 2 and the second joint 4 are threaded connected, the main shaft 3 is covered with a piston rod 5, the piston rod 5 is connected with a piston 6, one end of the first joint 2 is connected with a piston end cover 7, and the other end is connected with a first seal, and the second joint 4 passes through The second seal is connected with the main shaft 3, the first joint 2, the second joint 4 and the main shaft 3 enclose a transition chamber 8, the motor housing 1, the main shaft 3 and the piston end cover 7 enclose an inner chamber 9, and the first joint 2 A first pressure balance hole 10 is opened on it, and a second pressure balance hole 11 is opened on the piston end cover 7 .

[0045] The first seal is an end face mechanical seal, inc...

Embodiment 3

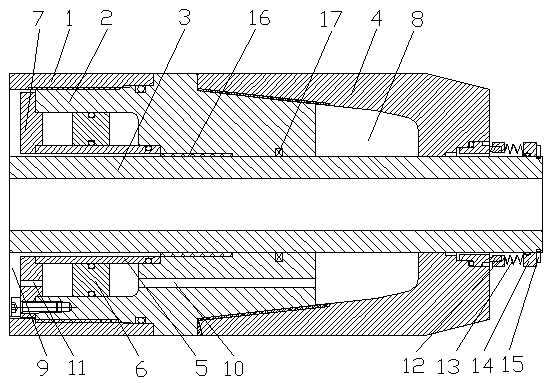

[0048] see image 3 , a spindle sealing system for motors working in high temperature or high pressure environments, including a first joint 2 connected to the motor housing 1 and a second joint 4 connected to the main shaft 3, the first joint 2 and the second joint 4 are threaded connected, the main shaft 3 is covered with a piston rod 5, the piston rod 5 is connected with a piston 6, one end of the first joint 2 is connected with a piston end cover 7, and the other end is connected with a first seal, and the second joint 4 passes through The second seal is connected with the main shaft 3, the first joint 2, the second joint 4 and the main shaft 3 enclose a transition chamber 8, the motor housing 1, the main shaft 3 and the piston end cover 7 enclose an inner chamber 9, and the first joint 2 A first pressure balance hole 10 is opened on it, and a second pressure balance hole 11 is opened on the piston end cover 7 .

[0049] The first seal is a radial seal, including a radial...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com