Tea seed grading winnowing machine

A technology for grading wind and tea seeds, which is applied in the direction of solid separation, separating solids from solids with air flow, chemical instruments and methods, etc., can solve the problems of high labor intensity, long construction period, high equipment cost, etc., and reduce the cost of equipment Damage, reduce wind loss, reduce the effect of erosion damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

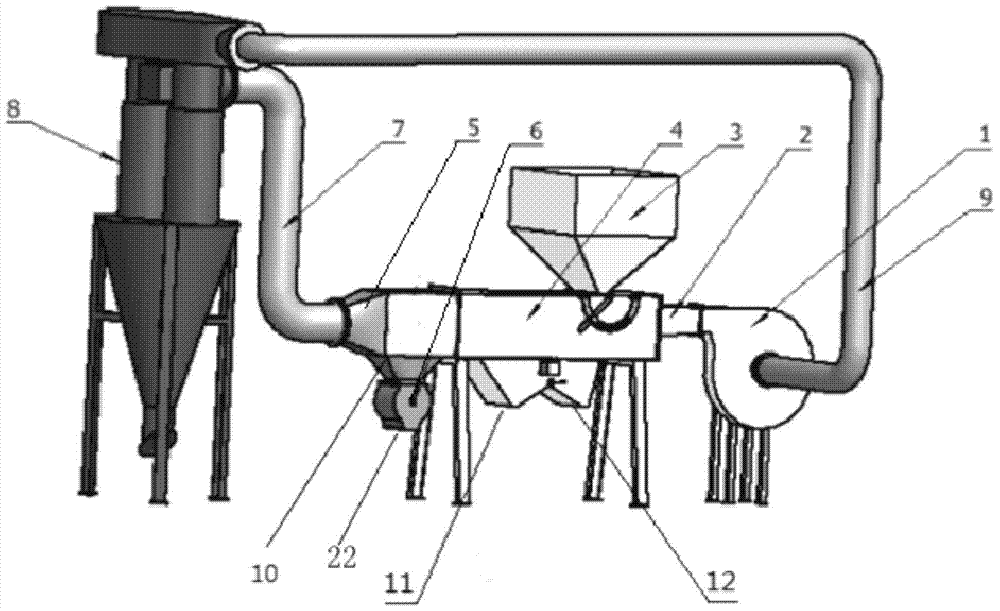

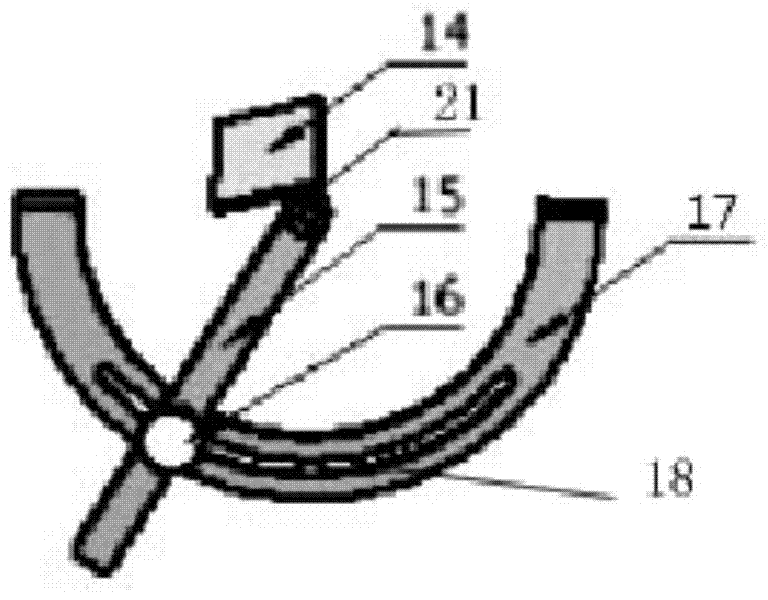

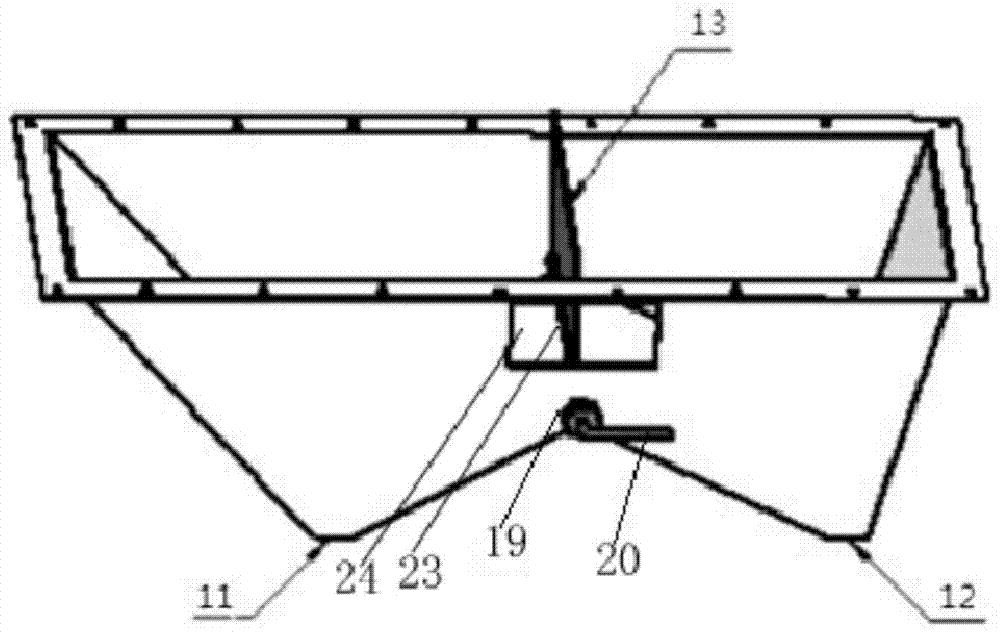

[0016] Embodiment 1 The embodiment includes a blower 1, an air duct 4, an air inlet pipe 7, a dust remover 8, and an air return pipe 9 connected in sequence; A hopper 12 for full seeds, a hopper 11 for seeds that is not full, and a hopper 10 for miscellaneous shells are provided in sequence. The bottom of the hopper 3 is provided with a blanking adjustment mechanism, which includes a blanking adjustment plate 14, a handle 15, a locking handwheel 16, and an arc guide plate 17. The blanking adjustment plate 14 and the handle 15 form an angle Fixedly connected, there is a locking hole on the handle, and the locking handwheel shaft passes through the arc guide groove 18 and the locking hole on the arc guide plate 17 in sequence, and the joint between the blanking adjustment plate and the handle is provided with a blanking hole. Articulation shaft 21. The shaft of the locking handwheel is provided with an external thread, the locking hole is provided with an internal thread, and t...

Embodiment 2

[0017] Embodiment 2 This embodiment is basically the same as Embodiment 1, the difference is that the two ends of the hinge shaft at the joint between the blanking adjustment plate and the handle are fixed on the hopper or on the frame, and the connection between the blanking adjustment plate 14 and the handle 15 The head is set on the hinge shaft and rotates around the hinge shaft.

[0018] The working process of the present invention is: the motor works to drive the blower 1 to rotate, and the wind enters the rectangular air inlet 2 to form a rectangular wind column with equal pressure. The hopper 3 falls into the air duct 4 at an inclined angle along the blanking adjustment plate 14. At this time, the strong wind blows the tea seeds and the shells to move forward. The density of the crushed shells is different, so under the action of wind blowing, the distance when falling to the bottom of the air duct 4 is different. The tea seeds with full particles fall to the full seed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com