A two-layer or multi-layer wear-resistant and impact-resistant pipe and its preparation method

An impact-resistant, double-layer technology, applied in the direction of pipes, pipe components, rigid pipes, etc., can solve the problems of poor wear resistance, short service life, poor wear resistance, etc., to ensure wear resistance, improve service life, and enhance The effect of abrasion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

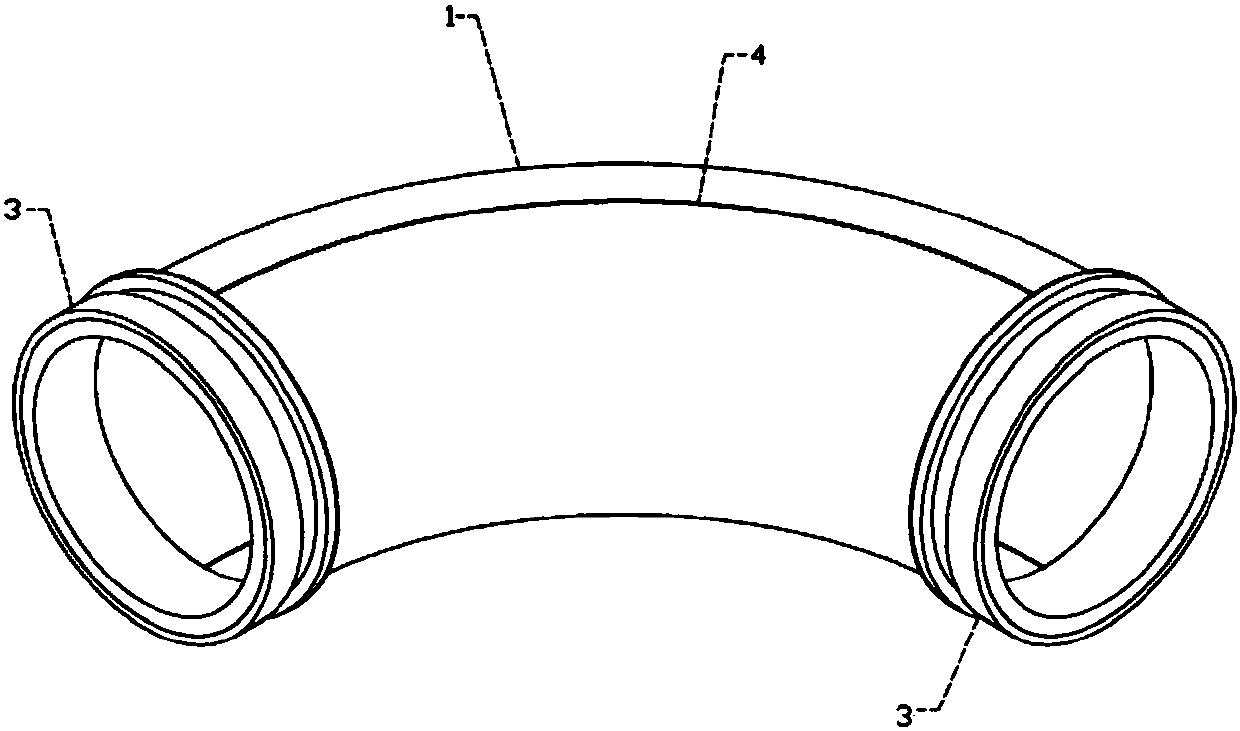

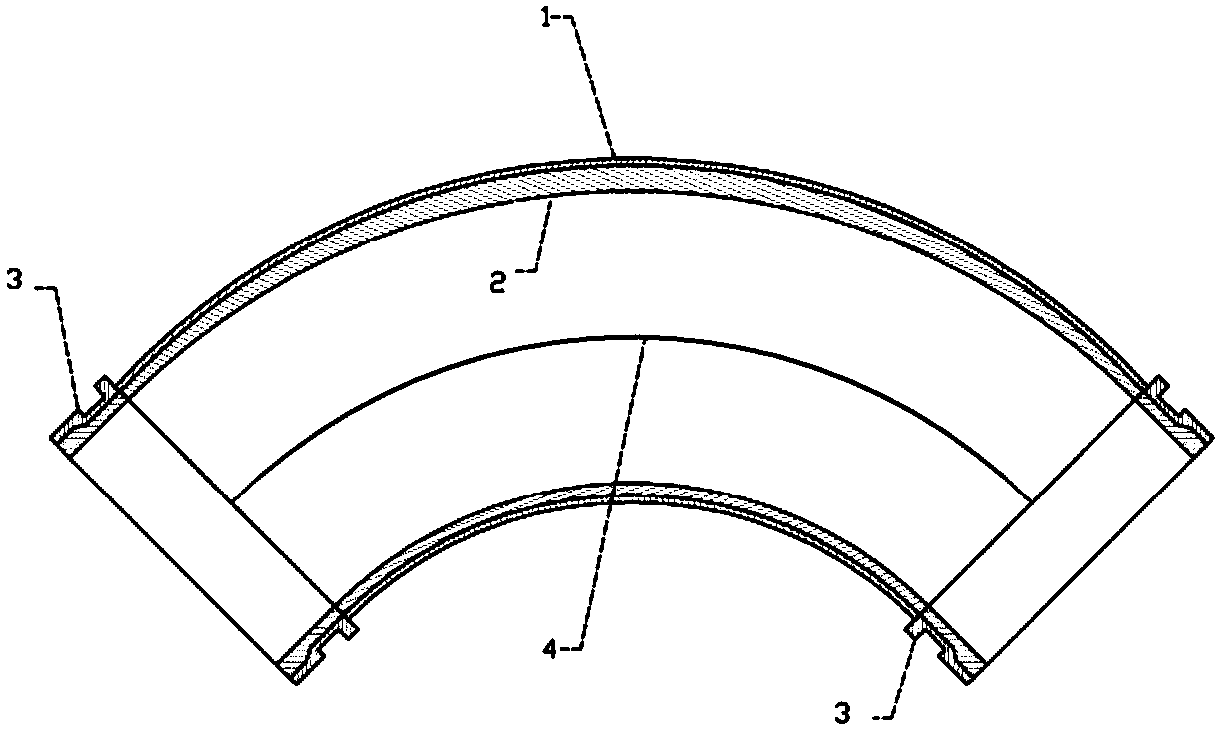

[0087] like Figure 1-3 As shown: In this embodiment, two or more double-layer wear-resistant and impact-resistant pipes are made into elbows, which are composed of an outer protective pipe 1 and an inner wear-resistant composite pipe 2, both of which are elbow structures . The inner wear-resistant composite pipe 2 is nested inside the outer protective pipe 1 . The outer protective tube 1 is used to protect the inner wear-resistant combined tube 2 to prevent the inner wear-resistant combined tube 2 from unnecessary damage during transportation, installation and use.

[0088] like Figure 4-16 As shown, the inner layer wear-resistant composite pipe 2 is divided into two parts: the inner layer wear-resistant large bend 8 and the inner layer wear-resistant small bend 12, both of which are semi-bent pipes, which are spliced together to form an inner layer with a circular cross section. Layer wear-resistant composite pipe2. The large wear-resistant bend 8 of the inner layer a...

Embodiment 2

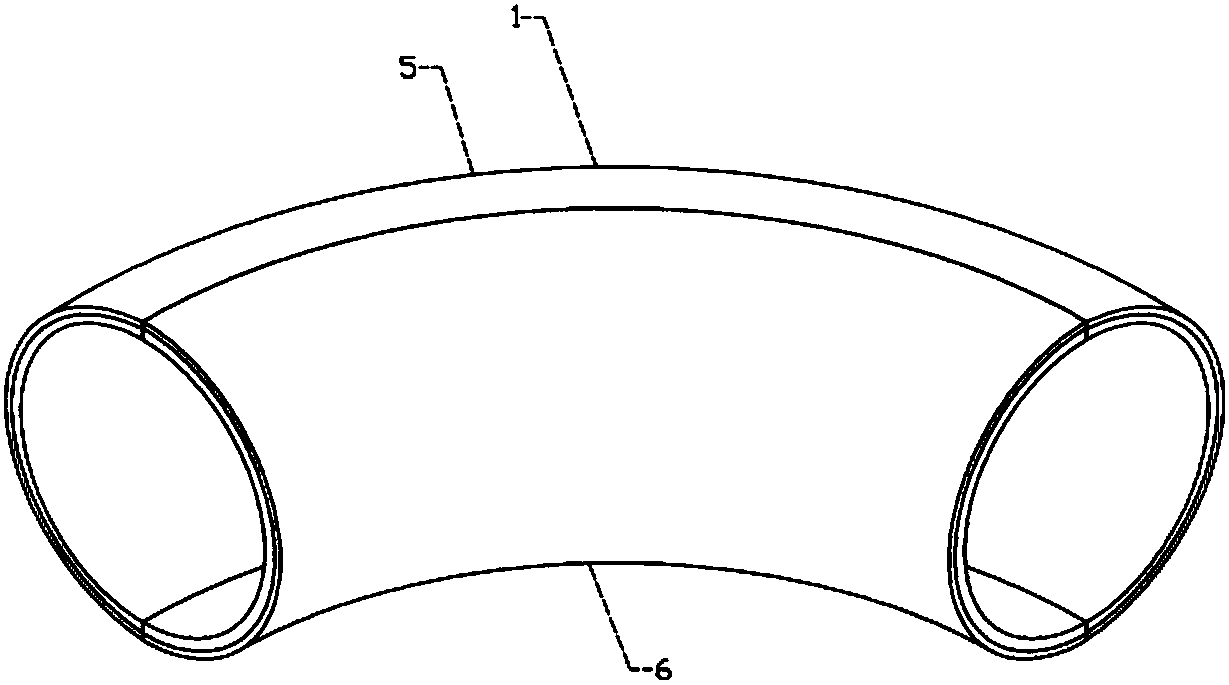

[0109] In this embodiment, another implementation manner of a two- or more-divided double-layered wear-resistant and impact-resistant tube is provided. like Figure 23 As shown, in this embodiment, the two- or more-divided double-layer wear-resistant and impact-resistant tube is composed of an outer-layer protection tube 1 and an inner-layer wear-resistant composite tube 2 . The inner layer wear-resistant composite tube 2 is nested inside the outer layer protection tube 1 . The outer layer protection tube 1 is used to protect the inner layer wear-resistant composite tube 2 to avoid unnecessary damage during transportation, installation and use.

[0110] The outer protection tube 1 is divided into two parts: a large-curved outer protection part 7 and a small-curved outer protection part 11 , which are welded together to form the outer protection tube 1 with an annular cross-section. The inner wear-resistant composite pipe 2 is divided into two parts: the inner wear-resistant ...

Embodiment 3

[0127] like Figure 24-25As shown in this embodiment, two or more double-layer wear-resistant and impact-resistant pipes are made into two double-layer straight pipes, which are composed of an outer protective pipe 1 and an inner wear-resistant combined pipe 2. All are straight pipe construction. The inner wear-resistant composite pipe 2 is nested inside the outer protective pipe 1 .

[0128] The inner wear-resistant composite pipe 2 is divided into two parts: the upper wear-resistant pipe wall 31 and the lower wear-resistant pipe wall 32, both of which are half-pipes with a semicircular cross-section, and are spliced together to form a ring-shaped cross-section Inner wear-resistant composite pipe 2. The upper wear-resistant pipe wall and the lower wear-resistant pipe wall are made of wear-resistant materials with different wear-resistant properties. Preferably, the wear resistance of the material used for the lower wear-resistant pipe wall is better than that of the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com